201 stainless steel sheet

Standard Stock Sizes: 1ft x 4ft, 2ft x 2ft, 2ft x 4ft, 4ft x 4ft, 4ft x 8ft, 4ft x 10ft or Cut to Size.

Thickness: 0.25mm-100mm

Width: 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc

Length: 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

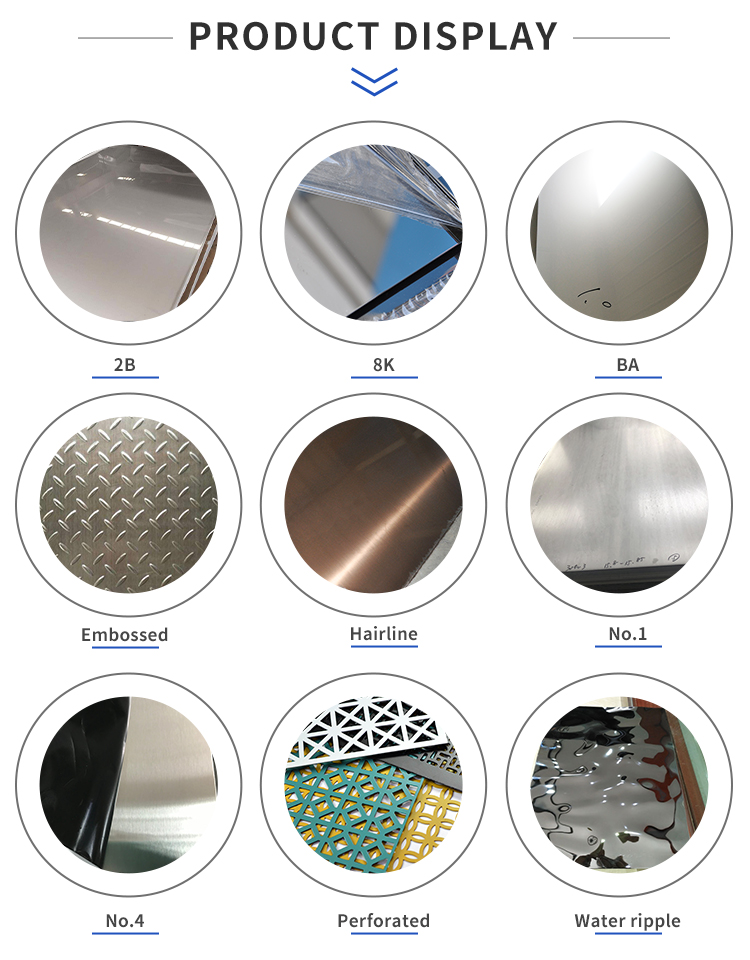

Surface: 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching, etc

Finish: Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated)

Our products: stainless steel including all sizes of steel coils, steel sheets, steel pipes, flat steel, angle steel, round steel, channel steel and other metal materials.

201 stainless steel has certain acid and alkali resistance, high density, no bubbles, no pinholes, etc. It is used to produce high-quality materials for various watch cases and watchband bottom covers. Mainly used to make decorative tubes, industrial tubes, and some shallow stretched products.

201 stainless steel is mainly an iron-carbon alloy composed of chromium, nickel, manganese and nitrogen, and the melting point of all alloys refers to a melting range, and the melting point varies with its chemical composition content. The melting range of 201 stainless steel is roughly: 1398 ~1454°C.

Alternative grades of equivalent materials

| China * GB | GB24511 | 12Cr17Mn6Ni5N |

| Japan | JIS | SUS201 |

| United States of America | ASTM | 201 |

| UNS | S20100 | |

| South Korea | KS | STS201 |

| European Union | BSEN | 1.4372 |

| India | IS | 10Cr17Mn6Ni4N20 |

| Australia | AS | 201-2 |

| Taiwan, China | CNS | 201 |

| Germany | DIN | X12CrMnNiN17-7-5 |

| United Kingdom | BS970 BS1449 | – |

| Belgium | BS970Part1 | X12CrMnNiN17-7-5 |

Standard Specification Of 201 Sheet

| Thickness | 0.25mm-100mm |

| Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

| Surface | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching, etc |

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

201 stainless steel composition content.

| Grade and Main Chemical Composition% | Grade | 201(mid copper) | 201(high copper) |

| C | ≤0.15 | ≤0.15 | |

| Si | ≤1.00 | ≤1.00 | |

| Mn | 10-11 | 9.5-10 | |

| P≤ | 0.045 | 0.04 | |

| S≤ | 0.03 | 0.03 | |

| Cr | 12-14 | 13-15 | |

| Mo | – | – | |

| Ni | 0.8-1.0 | 1.0-1.2 | |

| Other | Cu 0.8-1.0 | Cu 1.4-1.6 |

Tensile strength :520MPa

Yield strength :275MPa

Elongation :55 to 60%

How to distinguish the difference between 201 stainless steel and 304 stainless steel?

1. The composition of model 201 is 17Cr-4.5Ni-6Mn-N, which is a Ni-saving steel grade and a substitute steel for model 301. After cold processing, it has magnetism and is used in railway vehicles.

2. The composition of model 304 is 18Cr-9Ni, which is the most widely used stainless steel and heat-resistant steel. Used in food production equipment, Xitong chemical equipment, nuclear energy, etc.

3. 201 has high manganese content, the surface is very bright with dark and bright, and high manganese content is easy to rust. 304 contains more chromium, the surface is matte and does not rust. Putting the two together makes a comparison. The most important thing is that the corrosion resistance is different. The corrosion resistance of 201 is very poor, so the price is much cheaper. And because the 201 model contains low nickel, the price of the 201 model is lower than that of the 304 model, so the corrosion resistance is not as good as the 304 model.

4. The difference between 201 and 304 is the nickel content. And the price of 304 is more expensive now, but 304 can at least guarantee that it will not rust during use. (Use stainless steel potion for experiment)

5. Stainless steel is not easy to rust because the chromium-rich oxide formed on the surface of the steel body can protect the steel body. The 201 model is a high-manganese stainless steel with greater hardness, high carbon and low nickel than the 304 model.

Related News

Submitted successfully

We will contact you as soon as possible