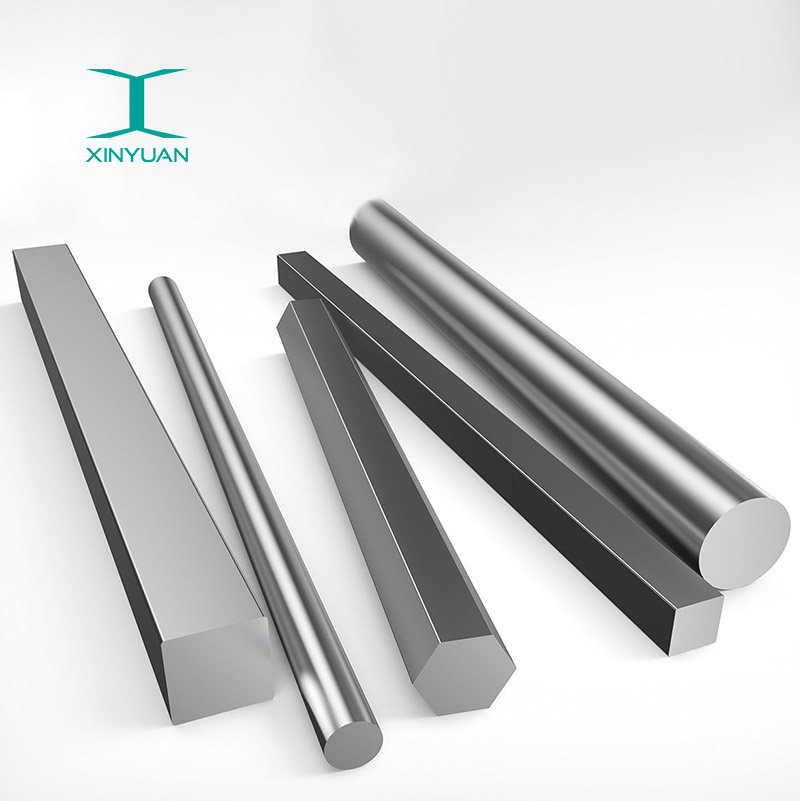

Customized Stainless Steel Bar

Stainless steel bar has broad application prospects, is widely used in hardware kitchenware, shipbuilding, petrochemical, machinery, medicine, food, electric power, energy, building decoration, nuclear power, aerospace, military industry and other industries! . Seawater equipment, chemical, dye, paper, oxalic acid, fertilizer and other production equipment; Food industry, coastal facilities, ropes, CD bars, bolts, nuts.Quality management :ISO9001:2000 quality management system certification, production license and so on!Note: we can customize Stainless steel bar of various materials and specifications.

Stainless steel bar has large utility possibilities, is widely utilized in hardware kitchenware, shipbuilding, petrochemical, equipment, medication, food, electric energy, power, building decoration, nuclear strength, aerospace, army industry and other industries! . Seawater device, chemical, dye, paper, oxalic acid, fertilizer and different manufacturing system; meals enterprise, coastal facilities, ropes, cd bars, bolts, nuts.excellent management :ISO 9001:2000 high-quality management system certification, production license and so forth!be aware: we can personalize stainless-steel bar of various substances and specs.

Technique | Forged/Hot Rolled/Cold Drawn/Peeled |

Category | 1.Round bar |

3. Flat bar | |

4. Hexagon bar | |

5. Channel bar | |

6. Threaded bar | |

7. Angle bar | |

Diameter± | H9 tolerance can reach the industry standard |

Standard | GB, AISI/JIS, SUS, UNS, DIN 17440 17220(BS970 Part4) |

Material | Stainless steel: |

1.with plastic cap to protect both ends

2.weaving bag wrapped outside the pipe

3.then pack into wooden case.

delivery detail:3or 5workdays since received the deposit of L/C draft.

Chemical Composition about stainless steel Round Bar

302 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 8.0-10.0 | 17.0-19.0 | - |

304 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 8.0-10.5 | 18.0-20.0 | - |

304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 9.0-13.0 | 18.0-20.0 | - |

309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 12.0-15.0 | 22.0-24.0 | - |

310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤0.03 | 19.0-22.0 | 24.0-26.0 | - |

316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

316L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 12.0-15.0 | 16.0-18.0 | 2.0-3.0 |

321 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 9.0-13.0 | 17.0-19.0 | - |

630 | ≤0.07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | 3.0-5.0 | 15.5-17.5 | - |

631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

904L | ≤2.0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0-28.0 | 19.0-23.0 | 4.0-5.0 |

2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

2507 | ≤0.03 | ≤0.80 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤0.03 | 0.19-0.22 | 0.24-0.26 | - |

410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | - | 11.5-13.5 | - |

430 | ≤0.12 | ≤0.75 | ≤1.0 | ≤0.040 | ≤0.03 | ≤0.60 | 16.0-18.0 | - |

Related News

Submitted successfully

We will contact you as soon as possible