253MA Stainless Steel Sheet

Thickness:0.3-260mm

Width:1000mm,1219mm,1500mm,2000mm,2500mm,3000mm etc

Length:1000mm,1500mm,2438mm,3000mm,5800mm,6000mm,9000mm,12000mm, etc

Products can be customized

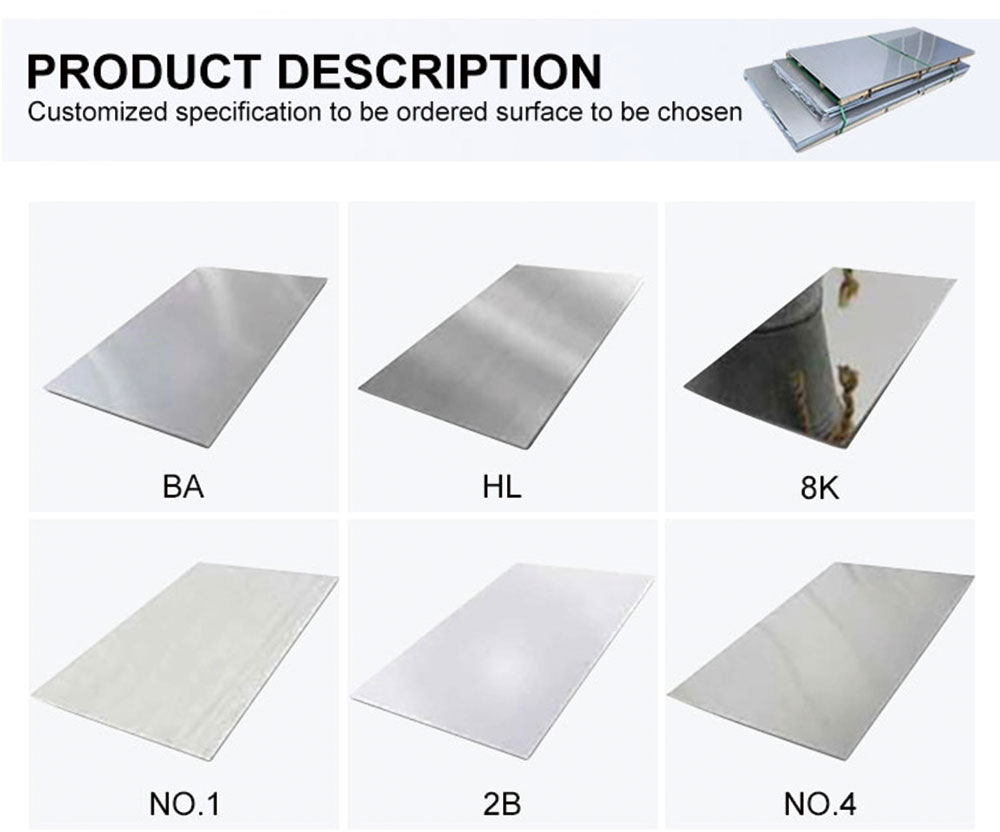

Surface:BA,2B,NO.1,NO.4,4K,HL,8K

Standard:ASTM,AISI,JIS,GB, DIN,EN

253MA is a heat resistant Austenitic stainless steel designed for applications requiring high creep strength and excellent corrosion resistance.

Product Name | |

Thickness | 0.3~260mm |

Width | 600mm,1000mm,1219mm,1500mm,1800mm,2000mm,2500mm, 3000mm, 3500mm,etc |

Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

Standard | ASTM GB/T JIS4 ASME BS DIN EN |

200 series: 201/202 300series:301/304/304L/305/309S/310S/316/316L/316LN/316Ti/317/317L/347/347H 400 series: 405/409/409L/410/420/430/440C/444/4447 600 series: 630/631 duplex stainless steel: 2205/2507/2520 super stainless steel: 904L | |

high hardness and strength/100% recycled/fire resistant/wter proof/anti corrosion/high temperature resistant/easy to clean and maintain/long lifetime/durable | |

Technique | |

Surface | 2B, 2D, BA, NO. 1, NO. 4, NO. 8, 8K, mirror,checkered,embossed,hair line, sand blast, Brush, etching, etc |

Price Term | Ex-Work, FOB, CNF, CFR, CIF, etc |

In addition to the alloying elements chromium and nickel, 253MA stainless steel also contains a small amount of Rare Earth Metals (REM), which significantly improves its antioxidant capacity. Nitrogen was added to improve creep properties and to make the steel completely austenitic. Although relatively low in chromium and nickel, this stainless steel has in many cases the same high temperature characteristics as highly alloyed alloy steels and nickel-based alloys.

EN | ASTM/UNS | C | N | Cr | Ni | Mo | COMPOMENT | |

1 | 0.04 | 18.1 | 8.3 | |||||

2 | 1.4307 | 0.02 | 18.1 | 8.3 | ||||

3 | 1.4541 | 0.04 | 17.3 | 9.1 | Ti0.24 | |||

4 | 1.4550 | 347 | 0.05 | 17.5 | 9.5 | Nb0.012 | ||

5 | 1.4401 | 316, S31608 | 0.04 | 17.2 | 10.2 | 2.1 | ||

6 | 1.4404 | 316L,S31603 | 0.02 | 17.2 | 10.2 | 2.1 | ||

7 | 1.4406 | 316LN | 0.02 | 0.14 | 17.2 | 10.3 | 2.1 | |

8 | 1.4429 | S31653 | 0.02 | 0.14 | 17.3 | 12.5 | 2.6 | |

9 | 1.4571 | 316Ti,S31635 | 0.04 | 17 | 10.6 | 2.1 | Ti0.30 | |

10 | 1.4438 | 317L,S31703 | 0.02 | 18.2 | 13.5 | 3.1 | ||

11 | 1.4439 | 317LMN | 0.02 | 0.14 | 17.8 | 12.6 | 4.1 | |

12 | 1.4435 | 316LMOD,724L | 0.02 | 0.06 | 17.3 | 13.2 | 2.6 | |

13 | 1.4539 | 904L,N08904 | 0.01 | 20 | 25 | 4.3 | 1.5Cu | |

14 | 1.4547 | S31254,254SMO | 0.01 | 0.02 | 20 | 18 | 6.1 | Cu 0.8-1.0 |

15 | 1.4529 | N08926,Alloy25-6mo | 0.02 | 0.15 | 20 | 25 | 6.5 | 1.0Cu |

16 | 1.4652 | S32654,654SMO | 0.01 | 0.45 | 23 | 21 | 7 | Mn2-4-Cu 0.3-0.6 |

17 | 1.4162 | S32101,LDX2101 | 0.03 | 0.22 | 21.5 | 1.5 | 0.3 | Mn 4-6-Cu 0.1-0.8 |

18 | 1.4362 | S32304,SAF2304 | 0.02 | 0.1 | 23 | 4.8 | 0.3 | |

19 | 1.4462 | 2205,S32205,S31803 | 0.02 | 0.16 | 22.5 | 5.7 | 3.0 | |

20 | 1.4410 | S32750,SAF2507 | 0.02 | 0.27 | 25 | 7 | 4 | |

21 | 1.4501 | S32760 | 0.02 | 0.27 | 25.4 | 6.9 | 3.5 | W 0.5-1.0-Cu0.5-1.0 |

22 | 1.4948 | 304H | 0.05 | 18.1 | 8.3 | |||

23 | 1.4878 | 321H, S32169,S32109 | 0.05 | 17.3 | 9 | TI0.2-0.7 | ||

24 | 1.4818 | S30415,153MA | 0.15 | 0.05 | 18.5 | 9.5 | Si1-2-Ce 0.03-0.08 | |

25 | 1.4833 | 309S,S30908 | 0.06 | 22.8 | 12.6 | |||

26 | 1.4835 | 30815,253MA | 0.09 | 0.17 | 21 | 11 | Si1.4-2.0Ce 0.03-0.08 | |

27 | 1.4845 | 310S,S31008 | 0.05 | 25 | 20 | |||

28 | 1.4542 | 630 | 0.07 | 16 | 4.8 | Cu3.0-5.0-Nb0.15-0.45 |

Package

*stainless steel sheet covered with wooden sheet to protect transportation

* All stainless steel plates will be packed in strong wooden cases

*each carton well supported and reinforced

*Take a picture of the case and seal it.

*The transportation is fast. And inform the customer every step

Application

253MA is widely used in sintering equipment, blast furnace equipment, steel melting, furnace and continuous casting equipment, rolling mill (heating furnace), heat treatment furnace and accessories, mineral equipment and cement production equipment, etc. 253MA steel can be used up to 900 ℃ pressure occasions and working temperature up to 1150 ℃ non-pressure high temperature parts.

Related News

Submitted successfully

We will contact you as soon as possible