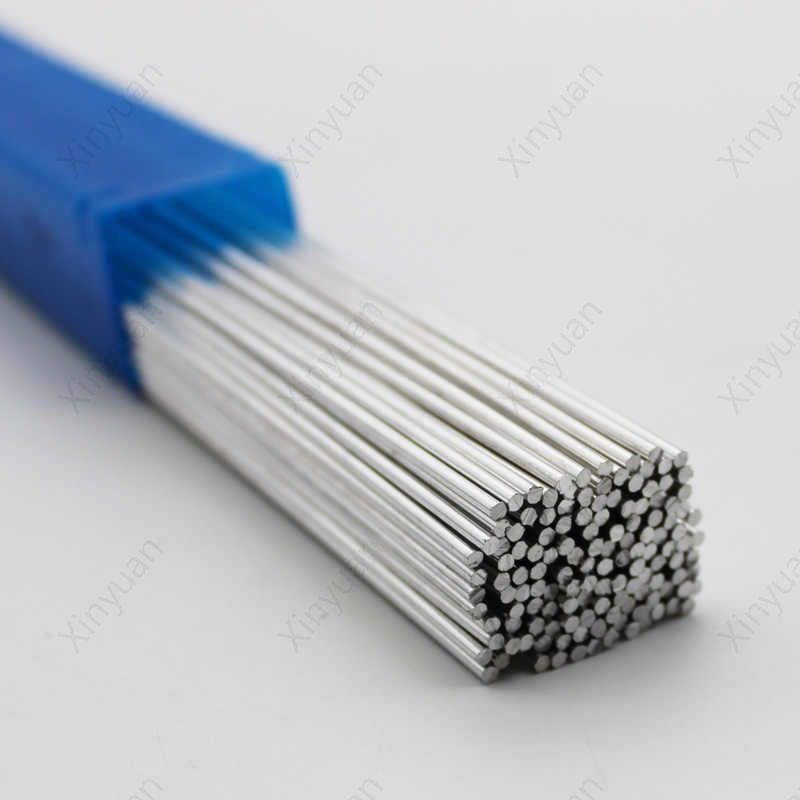

UGIMA 4301 (FG) Stainless Steel Wire

Stainless steel straight wire is generally made of ordinary carbon steel and high quality carbon steel. According to the steel distribution catalogue and different uses, wire products include ordinary low carbon steel hot rolled disk bar, high quality carbon steel wire rod, carbon electrode wire rod, quenching and tempering thread wire rod, wire rope wire rod, piano wire rod rod and stainless steel wire rod, etc.

The application of stainless steel flux cored wire is mainly MAG welding, MAG welding has the following characteristics; 1) Compared with manual welding, welding speed can be improved 2-4 times, its welding efficiency is up to 90%(stainless steel electrode only 55%)2) to the current, voltage adaptation range, welding conditions are easy to set, easy to conduct semi-automatic and automatic welding. 3) Good slag removal, welding pass surface gloss. In addition, the splash is very small, the arc stability is good, X-ray qualified.

A .Description

A. Stable arc, low splashing, high deposited effeciency, beautiful seam, suitable for all position;

B. Raw Material: TianJin Steel Mill;

C. The nearest port: TianJin Port;

D. Delivery Time: 7-15 days after your confirmed order;

E.OEM strictly according to customer's package design requirement

B.Welding Wire Chemical Composition(%)

Standard and steel grade | Gauge(mm) | Welding wire chemical composition(%) | |||||||

GB | AWS | DIN | 0.8-2.0 | C | Mn | Si | P | S | Cu |

ER50-6 | ER70S-6 | SG2 | 0.06-0.15 | 1.40-1.85 | 0.80-1.15 | ≤0.025 | ≤0.035 | ≤0.50 | |

C.Mechanical Properties of Deposited Metal

Mechanical properties of deposited metal | |||

(Mpa)Yield stength | (Mpa)Tensile strength | (%)Elongation | (°C)AKV impact |

≥420 | ≥500 | ≥22 | ≥27(-30) |

D. Specification and Reference Current

Diameter | φ0.8 | φ1.0 | φ1.2 | φ1.6 | All Position Welding |

(mm) | |||||

F Current (A) | 40~180 | 50~220 | 80~350 | 170~550 | |

Please noted | The wires must be kept in dry. Open the package | ||||

only when welding to avoid rusting. | |||||

Before welding, please clean oil, rust, water, etc. from the work piece. | |||||

Related News

Submitted successfully

We will contact you as soon as possible