MAG Stainless Steel Flux Cored Wire

Stainless steel flux cored wire can be like carbon steel and low alloy steel flux cored wire, stainless steel is simple and efficient welding, the application of stainless steel flux cored wire is mainly MAG welding, MAG welding has the following characteristics; 1) Compared with manual welding, welding speed can be improved 2-4 times, its welding efficiency is up to 90% (stainless steel electrode only 55%) 2) to the current, voltage adaptation range, welding conditions are easy to set, easy to conduct semi-automatic and automatic welding. 3) Good slag removal, welding pass surface gloss.

Stainless-steel flux cored cord may be like carbon metal and coffee alloy steel flux cored cord, chrome steel is simple and efficient welding, the application of chrome steel flux cored cord is specially magazine welding, mag welding has the following characteristics; 1) in comparison with manual welding, welding pace can be improved 2-4 instances, its welding performance is as much as ninety% (stainless-steel electrode only fifty five%) 2) to the cutting-edge, voltage adaptation variety, welding situations are smooth to set, smooth to conduct semi-computerized and automatic welding. 3) accurate slag removal, welding skip surface gloss.

Diameter(mm) | 1 | 1.2 | 1.4 | 1.6 | |

Current(A) | F | 100-280 | 100-300 | 150-380 | 180-430 |

HF | 100-280 | 120-280 | 150-320 | 180-380 | |

V | 80-280 | 120-260 | 150-270 | 180-280 | |

H | 100-260 | 120-280 | 150-320 | 180-330 | |

VD | 100-260 | 200-280 | 220-300 | 250-300 | |

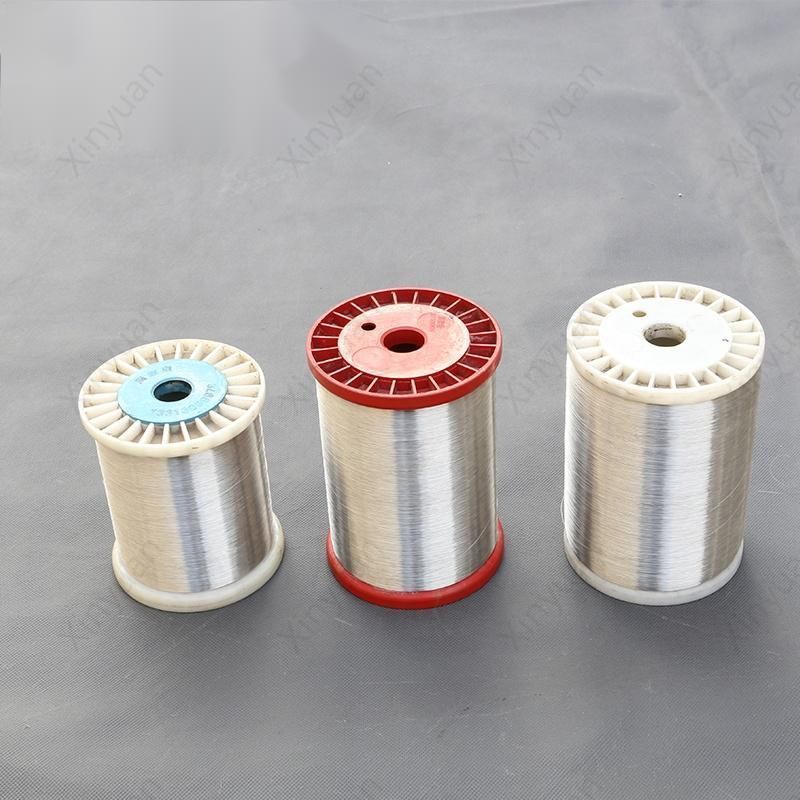

Description | Manufacturer direct sell aisi 201 202 304 304L 304HC 316 316L 321 430 904L 2205 stainless steel wire |

Type | 201,202,301,303,304,304L,310,316,316L,321,410,420,430,431 |

Diameter | 0.1mm-15mm |

Length | as requested |

Surface | bright, cloudy,plain,black |

Standard | ASTM A240,GB/T3280-2007,JIS4304-2005,ASTM A167, |

Certificate | SGS,BV,API,BSI,GHC. |

Productivity | 2300 tons per month |

Packing | Standard export package,suit for all kinds of transport,or |

Application | lifting, fixing, cableway, hanging, haulage, etc. |

Delivery time | 10-15 days after receiving deposit |

Varieties | Deposited Metal Mechanical Properties | Wire Chemical composition | |||||||

Tensile Strength(Mpa) | Elogation | C | Si | Mn | Cr | Ni | Mo | other | |

ER307 | 612 | 43 | 0.07 | 0.47 | 3.95 | 20.4 | 9.65 | ||

607 | 41 | 0.04 | 0.34 | 1.82 | 20.13 | 9.5 | |||

ER308L | 578 | 42 | 0.024 | 0.42 | 1.65 | 20.1 | 10.33 | ||

ER308LSi | 585 | 39 | 0.02 | 0.7 | 1.47 | 20.11 | 10.5 | ||

ER309 | 607 | 40 | 0.083 | 0.42 | 1.63 | 23.83 | 13.13 | ||

ER309L | 588 | 43 | 0.023 | 0.39 | 1.98 | 23.88 | 12.9 | ||

ER309LSi | 577 | 32 | 0.022 | 0.87 | 1.55 | 24.1 | 13 | ||

Related News

Submitted successfully

We will contact you as soon as possible