304 Stainless Steel Coil

304 stainless steel is a common stainless steel material, density of 7.93 g/cm³, the industry is also known as 18/8 stainless steel. High temperature resistance of 800℃, with good processing performance, high toughness, widely used in industry and furniture decoration industry and food and medical industry.

The common marking methods in the market include 06Cr19Ni10 and SUS304, in which 06Cr19Ni10 generally means national standard production, 304 generally means ASTM standard production, and SUS304 means daily standard production.

304 is a universal stainless steel, which is widely used in the manufacture of equipment and parts requiring good comprehensive properties (corrosion resistance and formability). To maintain the corrosion resistance inherent in stainless steel, the steel must contain at least 18% chromium and at least 8% nickel. 304 stainless steel is a brand of stainless steel produced in accordance with ASTM standards in the United States.

304 stainless steel is a common stainless steel material, density of 7.93 g/cm³, the industry is also known as 18/8 stainless steel. High temperature resistance of 800℃, with good processing performance, high toughness, widely used in industry and furniture decoration industry and food and medical industry.

The common marking methods in the market include 06Cr19Ni10 and SUS304, in which 06Cr19Ni10 generally means national standard production, 304 generally means ASTM standard production, and SUS304 means daily standard production.

304 is a universal stainless steel, which is widely used in the manufacture of equipment and parts requiring good comprehensive properties (corrosion resistance and formability). To maintain the corrosion resistance inherent in stainless steel, the steel must contain at least 18% chromium and at least 8% nickel. 304 stainless steel is a brand of stainless steel produced in accordance with ASTM standards in the United States.

Commodity | Hot and cold rolled stainless steel coil/sheet/pipe/strip |

Grade | 201,202,301,304,304j1,304l,321,309s,310s,2205,409l,410,410s,420,420j1,420j2,430,439,409l, |

443,444,etc | |

Standard | ISO,JIS,ASTM,AS EN,GB |

surface | NO.1 /NO.2D /NO.2B /BA /NO.3 /NO.4 /NO.240 /NO.320 /NO.400 /HL /NO.7/ NO.8,etc |

Thickness | 0.2-100mm(common:0.2-0.5mm)(Precision Stainless Steel Strip:0.05mm) |

Width | 100-2000mm |

Specification | 1000*2000/L,1219*2438/L,1500*3000/L,1500*6000/L,1800*6000/L,2000*6000/L,2200*6000/L |

Coil weight | 3-20MT/Coil or as your request |

MOQ | 5MT |

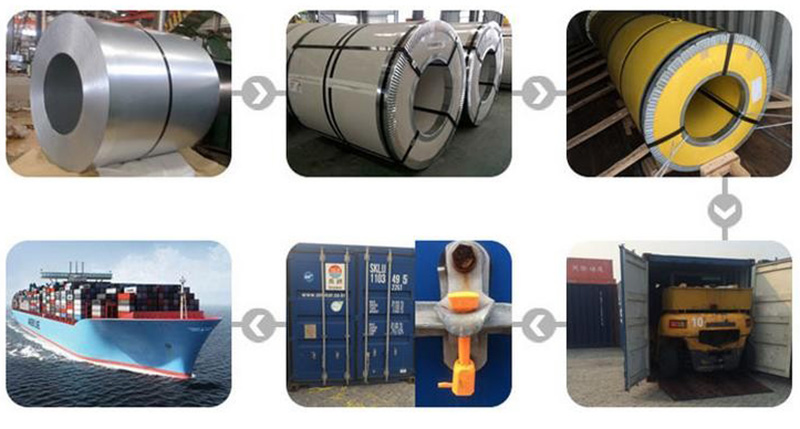

Packaging | Export standard, seaworthy |

ID | 508mm or 610mm |

Trade Term | FOB, CFR, CIF |

Transport Type | Container , bulk and train |

Loading port | Shanghai |

Payment terms | T/T, L/C at sight,West Union,D/P,D/A,Paypal |

Delivery time | 15-35days after confirmed order |

Chemical Composition

Grade | C | Si | Mn | P | S | Ni | Cr | Mo |

201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3 | |

≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3 | |

321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13 .0 | 17.0 -1 9.0 | - |

630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

904L | ≤ 2 .0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 | |

2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0 .26 | - |

410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | - |

Surface Finish | Characteristics and application |

2B | The surface brightness and flatness of NO.2B is better than NO.2D. then through a special surface treatment to improve its mechanical properties,No.2B could nearly satisfy comprehensive uses. |

NO.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

NO.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No.3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Related News

Submitted successfully

We will contact you as soon as possible