416 Stainless Steel Square Bar

416 is a martensitic free machining stainless grade providing excellent machinability. 416 Stainless Steel Square Bar has reasonable strength and corrosion resistance. The higher sulphur content improves the machining and non-galling characteristics.

Yield Strength: 40,000 psi

Hardness: Rockwell B95 (Medium)

Heat Treatment: Annealed (Softened)

Heat Treatable: Yes

Max. Hardness After Heat Treatment: Rockwell C40

Specifications Met: ASTM A582

416 Stainless Steel Square Bar

416 Stainless Steel Square Bar is a martensitic-free machining grade of stainless that can be hardened by heat treatment to achieve elevated strength and hardness. Due to its low cost and ready machinability,416 Stainless Steel Square Bar is readily used in its highly tempered state. 416 Stainless Steel Square Bar exhibits better machining characteristics than austenitic grades, however, sacrifices corrosion resistance. High sulfur, free-machining grades like Alloy 416 are unsuitable for marine or any chloride exposure situations.

Product Parameter:

Analysis

| Grade | C | Mn | P | S | Si | Cr | Ni | Mo |

| 416 Stainless Steel | 0.09 – 0.15% | 1.50% max | 0.06% max | 0.15 – 0.35% | 1.00% max | 11.50 – 13.50% | 1.00% max | 0.60% max |

Typical Mechanical Properties

| Condition | Tensile N/mm² | Yield N/mm² | Elongation % | Izod KCV J | Hardness Brinell |

| P | 550 – 700 | 340 | 15 | 34 | 152 – 207 |

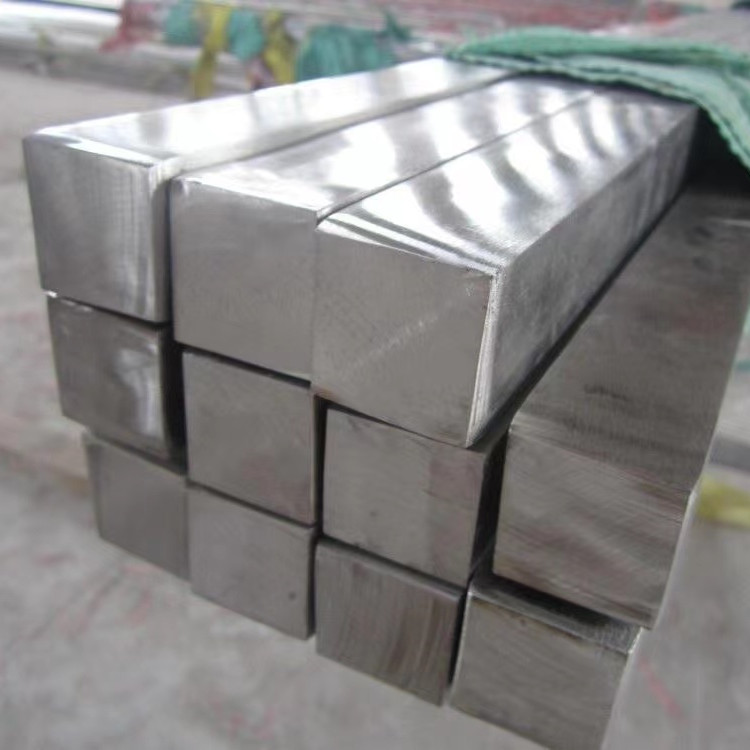

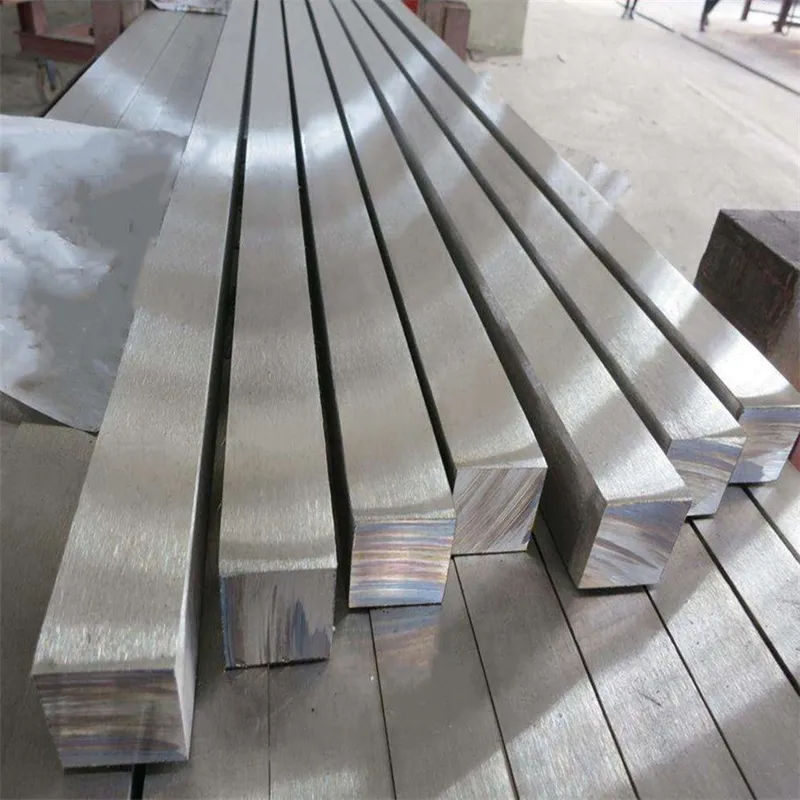

Product Display

Applications:

416 Stainless Steel Square Bar is generally used for parts that are extensively machined and require the corrosion resistance of a 13% chromium stainless steel. Applications that generally use 416 Stainless Steel Square Bar include:

Electrical motors

Nuts and bolts

Pumps

Valves

Automatic screw machine parts

Washing machine components

Studs

Gears

Quality inspection

Packaging and transportation

Our factory

Qualification Patent:

Related News

Submitted successfully

We will contact you as soon as possible