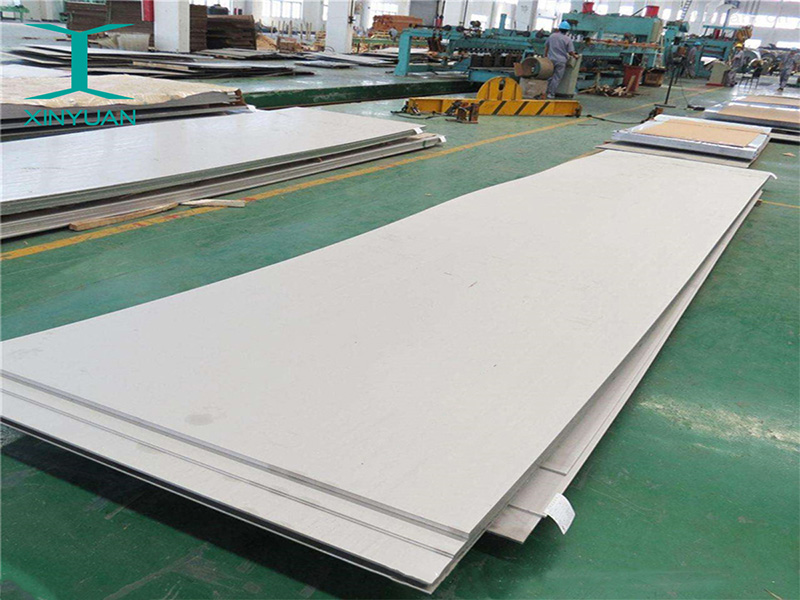

904L Stainless Steel Plate

Stainless steel plate is a kind of hollow section with no seams around.The thicker the thickness of the product, stainless steel plate is more economical and practical, the thinner the wall thickness, Stainless steel plate's processing costs will rise significantly.

Stainless steel plate of its limited performance of the decision, the general low precision seamless steel pipe : Wall thickness is not uniform, stainless steel plate's surface brightness is low, stainless steel plate's cost of high-length, and the appearance of pitting, black spots are not easy to remove.

Stainless steel plate is detection and shaping must be off-line processing. So stainless steel plate in the high-pressure, high strength, mechanical structure of timber reflects stainless steel plate's superiority.

Products Description

Stainless steel plate is a type of hollow segment without a seams around.the thicker the thickness of the product, chrome steel plate is extra low cost and practical, the thinner the wall thickness, stainless-steel plate's processing charges will upward push significantly.

Product Name | l stainless steel plate |

Thickness | 0.1~150mm |

Width | 600mm,1000mm,1219mm,1500mm,1800mm,2000mm,2500mm, 3000mm, 3500mm,etc |

Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

Standard | ASTM GB/T JIS4 ASME BS DIN EN |

Material | 200 series: 201/202 |

Feature | high hardness and strength/100% recycled/fire resistant/wter proof/anti corrosion/high temperature resistant/easy to clean and maintain/long lifetime/durable |

Technique | |

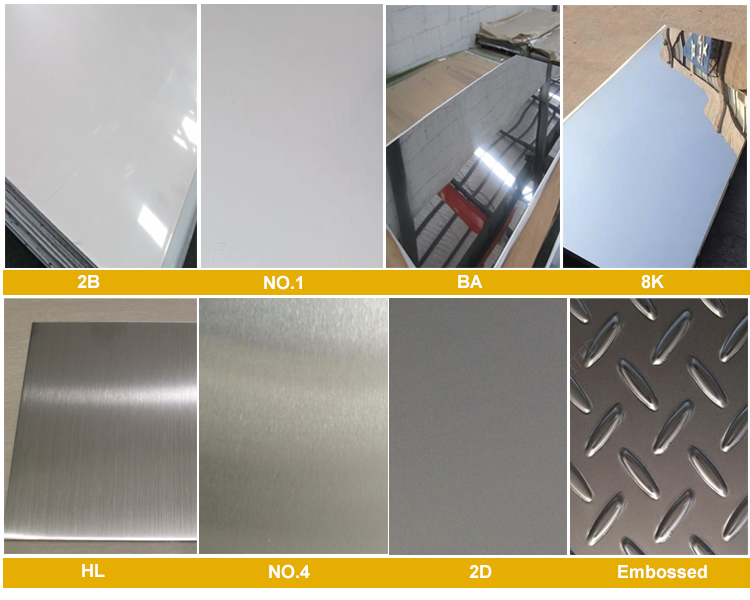

Surface | 2B, 2D, BA, NO. 1, NO. 4, NO. 8, 8K, mirror,checkered,embossed,hair line, sand blast, Brush, etching, etc |

Price Term | Ex-Work, FOB, CNF, CFR, CIF, etc |

Chemical Composition

Grade | C | Si | Mn | P | S | Ni | Cr | Mo |

201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3 |

316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3 |

≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13 .0 | 17.0 -1 9.0 | - | |

630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

904L | ≤ 2 .0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0 .26 | - |

410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | - |

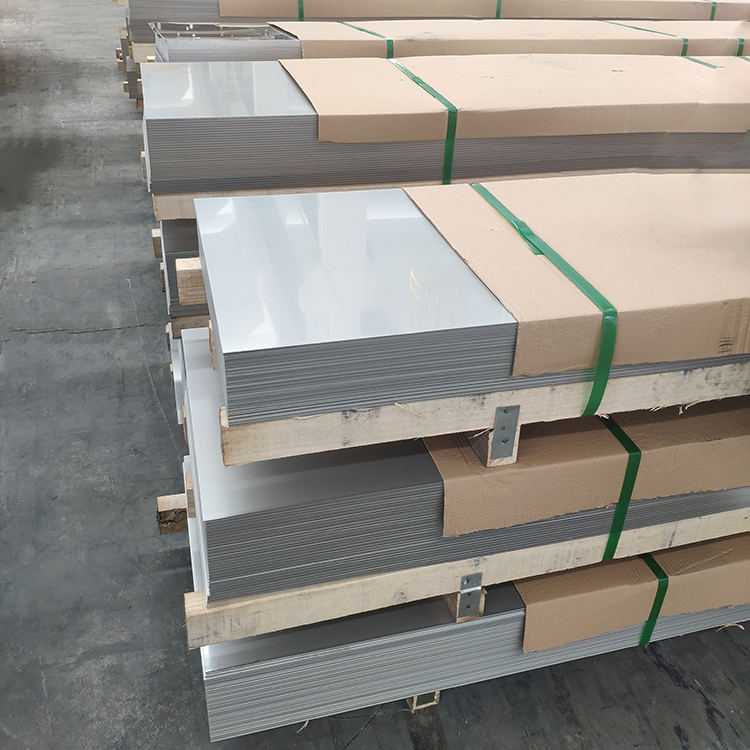

Packaging & Shipping

Related News

Submitted successfully

We will contact you as soon as possible