SRMM Cr Ferritic Stainless Steel Coil

Ferritic stainless steel (400 series) contains 15%~30% chromium and has a body centered cubic crystal structure. This kind of steel generally does not contain nickel, sometimes also contains a small amount of Mo, Ti, Nb and other elements, this kind of steel has the characteristics of large thermal conductivity, small expansion coefficient, good oxidation resistance, excellent stress corrosion resistance, etc., used for the manufacture of atmospheric resistance, water vapor, water and oxidizing acid corrosion parts. The price of ferritic stainless steel is not only relatively low and stable, and has many unique characteristics and advantages, has proved that in many of the original thought can only use austenitic stainless steel (300 series) application field, ferritic stainless steel is a very excellent alternative material, ferritic stainless steel does not contain nickel, the main element is chromium (gt; 10%) and iron, chromium is a particularly corrosion resistant element in stainless steel, and its price is relatively stable.

Stainless steel with 12%~30% chromium and ferritic matrix of body - centered cubic lattice at high temperature and room temperature. This kind of steel generally does not contain nickel, some contain a small amount of molybdenum, titanium or niobium and other elements, with good oxidation resistance, corrosion resistance and chloride corrosion cracking resistance. Ferritic stainless steel according to the chromium content can be divided into low chromium, medium chromium and high chromium three, according to the purity of steel, especially carbon, nitrogen impurities can be divided into ordinary ferritic stainless steel and ultra-pure ferritic stainless steel. Ordinary ferritic stainless steel has low temperature and room temperature brittleness, notch sensitivity and high intergranular corrosion tendency, poor weldability and other shortcomings, although this kind of steel development earlier, in the industrial application has been very limited. These deficiencies of ordinary ferritic stainless steel are related to the purity of steel, especially the higher content of interstitial elements such as carbon and nitrogen in steel. As long as the carbon and nitrogen in steel are low enough, such as not more than 150×10~250×10, the above shortcomings can be basically overcome. Since 1970s, due to the development of smelting technology, especially vacuum metallurgy and secondary refining process, high purity ferritic stainless steel with c + N ≤150~250×10 has been produced, which makes this kind of steel widely used in industry.

Commodity | Hot and cold rolled stainless steel coil/sheet/pipe/strip |

Grade | 201,202,301,304,304j1,304l,321,309s,310s,2205,409l,410,410s,420,420j1,420j2,430,439,409l, |

443,444,etc | |

Standard | ISO,JIS,ASTM,AS EN,GB |

surface | NO.1 /NO.2D /NO.2B /BA /NO.3 /NO.4 /NO.240 /NO.320 /NO.400 /HL /NO.7/ NO.8,etc |

Thickness | 0.2-100mm(common:0.2-0.5mm)(Precision Stainless Steel Strip:0.05mm) |

Width | 100-2000mm |

Specification | 1000*2000/L,1219*2438/L,1500*3000/L,1500*6000/L,1800*6000/L,2000*6000/L,2200*6000/L |

Coil weight | 3-20MT/Coil or as your request |

MOQ | 5MT |

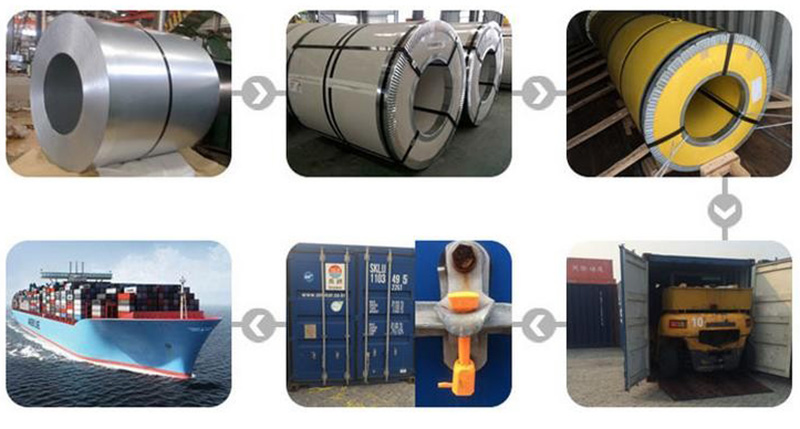

Packaging | Export standard, seaworthy |

ID | 508mm or 610mm |

Trade Term | FOB, CFR, CIF |

Transport Type | Container , bulk and train |

Loading port | Shanghai |

Payment terms | T/T, L/C at sight,West Union,D/P,D/A,Paypal |

Delivery time | 15-35days after confirmed order |

Fold ordinary ferrite

This type of steel includes low, medium and three chromium content. Low chromium ferritic stainless steel, chromium about 11%~14%, such as China 00Cr12, 0Cr13Al. AISI400, 405, 406 mf-2 in the United States (see table). This kind of steel has good toughness, plasticity, cold deformation and weldability. Because the steel contains a certain amount of chromium and aluminum, it has good oxidation resistance and rust resistance. The 405 can be used as oil refining towers, tank linings, steam turbine blades, high-temperature sulfur corrosion resistant devices, etc. 400 for household and office appliances, etc. 409 is used for automobile exhaust muffler system and cold and warm water pipe. Chromium ferritic stainless steel, chromium content of 14%~19%, such as China's 1Cr17, 1Cr17Mo. AISI429, 430, 433, 434, 435, 436, 439 in the United States. This kind of steel has better rust resistance and corrosion resistance. Its work hardening coefficient is small (N ≈2), and it has good deep drawing performance, but poor ductility. 430 is used for building decoration, automobile decoration, kitchen equipment, gas burners and components of nitric acid industrial installations, etc. The 434 is used for automotive, exterior decoration of buildings. 439 used as gas water heater, coal, gas pipeline hose, etc. High chromium ferritic stainless steel contains 19%~30% chromium, such as China's Cr18Si2, Cr25, the United States of AISI442, 443, 446. This kind of steel has good oxidation resistance. 442 is used intermittently in the atmosphere, with an upper limit of 1035℃ and a maximum continuous temperature of 980℃. 446 has better antioxidant properties.

Folded high purity ferrite

This type of steel contains very low carbon, nitrogen; High chromium, molybdenum, titanium, niobium and other elements. For example, Chinese 00Cr17Mo, 00Cr18Mo2, 00Cr26Mol, 00Cr30Mo2 overseas 18-2, Cr26Mol, 25CR-5Ni-4MO-Nb, MoNiT, AL29-4, AL29-4-2. This kind of steel has good mechanical properties (especially toughness), welding properties, intergranular corrosion resistance, pitting corrosion resistance, crevice corrosion resistance, excellent stress corrosion cracking resistance. For example, 18-2 has good corrosion resistance in nitric acid, acetic acid, NaOH, pitting resistance in 3%NaCl and FeCl3 is equal to or more than 18-8 austenitic steel, SCC resistance is far more than 18-8 steel. 26CrMo steel is resistant to corrosion in many media, especially in organic acids, oxidizing acids, and strong bases. It has good pitting resistance in strong chloride medium. Stress corrosion cracking does not occur in chloride, hydrogen sulfide, excessive sulfuric acid and strong alkali. 30CR-2Mo has higher pitting and crevice corrosion resistance while maintaining stress corrosion resistance. Steel with a small amount of nickel added to improve its properties in reducing acids.

Chemical Composition

Grade | C | Si | Mn | P | S | Ni | Cr | Mo |

201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3 | |

≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3 | |

321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13 .0 | 17.0 -1 9.0 | - |

630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

904L | ≤ 2 .0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 | |

2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0. 22 | 0. 24 -0 .26 | - |

410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | - |

Surface Finish | Characteristics and application |

2B | The surface brightness and flatness of NO.2B is better than NO.2D. then through a special surface treatment to improve its mechanical properties,No.2B could nearly satisfy comprehensive uses. |

NO.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

NO.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No.3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Related News

Submitted successfully

We will contact you as soon as possible