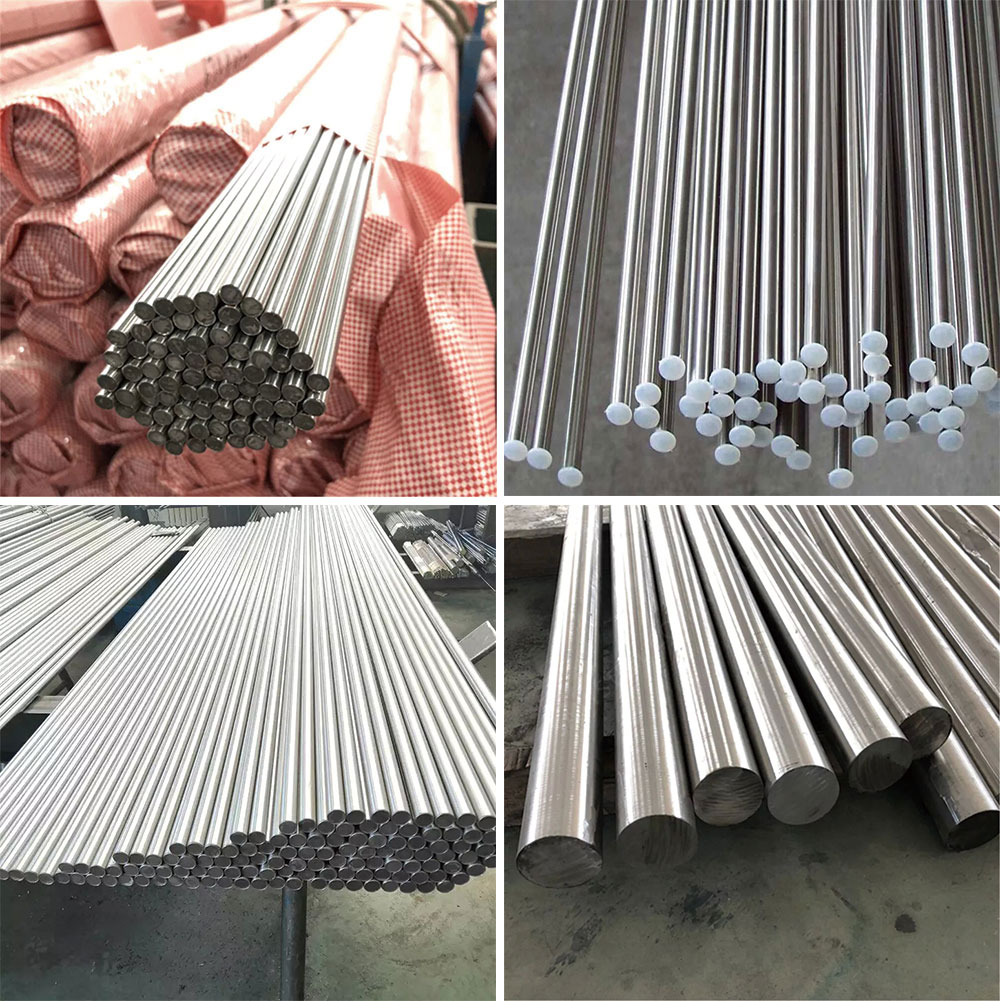

304L Stainless Steel bar

Outer Diameter:4-600mm (3/8"-25")

Length: 3000,5800,6000,9000,12000, etc

Products can be customized

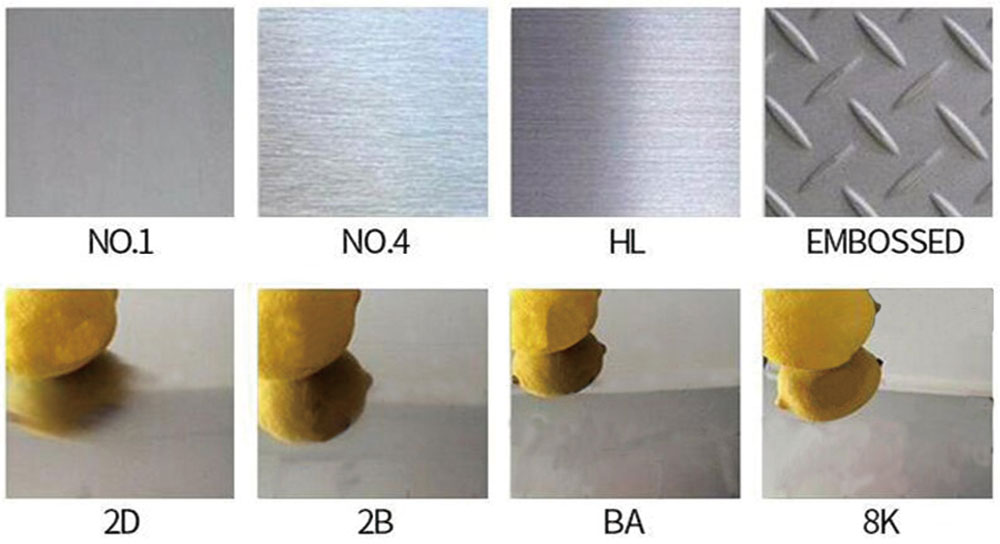

Surface:BA,2B,NO.1,NO.4,4K,HL,8K

Standard:ASTM,AISI,JIS,GB, DIN,EN

Product Details

Popular for its corrosion resistance, stainless steel rod is used in a wide range of applications including the construction of building foundations, bridges, and marine environments.We have black bright surface, and different materials such as 201 304 304L 316 316L 2205 2507 430 420 410 for you to choose.

Typical Mechanical Properties

Comparative Characteristics and Applications

Surface

Applications

Packing Information of Stainless steel bars

Seaworthy fuming wooden box export packing, suitable for long distance ocean transportatio

Product form

Related News

Submitted successfully

We will contact you as soon as possible

Close