Inconel 825 Pipe

Inconel 825 Pipe's chemical composition provides great resistance to many corrosive environments, such as pitting, crevice corrosion, intergranular corrosion, and stress- corrosion cracking. Inconel 825 Pipe has good mechanical properties from moderate to high temperatures. The hot- working range for Incoloy 825 is 1600 to 2150o F. The material has good weldability for all conventional processes.

Incoloy 825 Seamless Pipe

Size: 4 - 219mm

Thickness : 0.5 - 20mm

Length: Single, Double Random & Cut Length

Incoloy 825 Welded Pipe

Size: 5.0 - 1219.2 mm

Thickness : 0.5 - 20mm

Length: Single, Double Random & Cut Length

Inconel 825 Pipe

Inconel 825 Pipes are constructed from primary factors like iron, nickel, and chromium, which supply the primary resistance to rusting and pitting in ordinary temperatures. Inconel 825 Pipe has some introduced factors in small parts like molybdenum, titanium, and copper which provides greater substance to the product and will increase its workability even in marine conditions. These chemical houses assist the alloy to stand up to the underwater surroundings and forestall it from Intergranular corrosion, crevice corrosion, pitting, stress corrosion cracking, and different corrosives.

Product Parameter

| Incoloy 825 pipes Length |

|

| Wall Thickness | 0.1 to 60 milimeter |

| Standard | GB, ASTM, JIS, EN, GOST, AISI, DIN, ASME, AMS |

| Surface Finish | Bright, Cold Finish, Annealing, Polished, Pickling, or as per need |

| Incoloy 825 pipes Technique | Hot Rolled/ Cold Rolled |

| Inconel Alloy 825 pipes Manufacturing Shapes | Square, Round, Box Section, Rectangle |

| Manufacturing types | Seamless, ERW, Welded, EFW |

| Inspection, Test Reports | PMI Test Reports, EN 10204 3.1, Mill Test Certificates, Mechanical Reports, Chemical Reports, Visual Inspection Reports, NABL Approved Lab Reports, Third Party Inspection, Destructive and Non Destructive Test Reports |

| Manufacturing Technology | Cold / Hot Formed |

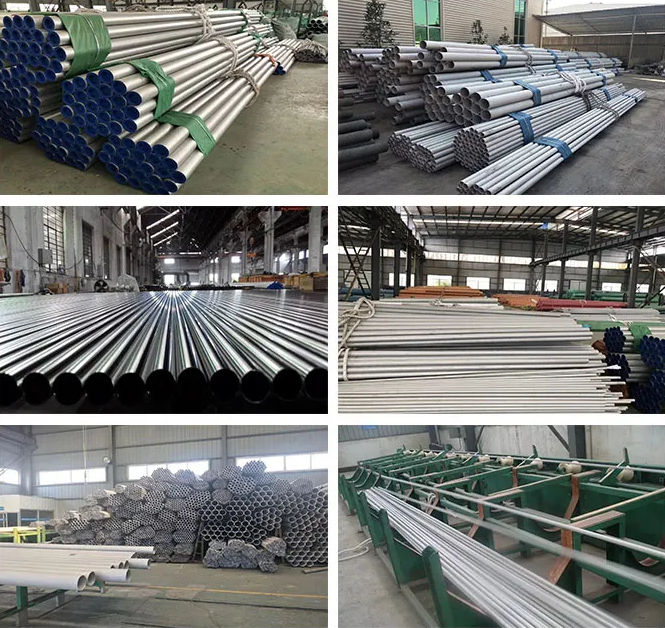

Product Display

Application

Inconel 825 Pipe is widely used in oil and gas applications. Other uses include chemical process equipment, exhaust systems, and power generation. CRA offers specialty Inconel 825 Pipe for use in multiple industries and applications, including:

Corrosive well conditions containing the presence of CO2 , H2S, and chlorides, in temperatures up to 300°F, without the presence of sulfur

Tubing, Casing, & Liners

Base Pipe for Sand Screens

Swell Packers

Exhaust Systems

Chemical Processing

Power Generation

Geothermal

Carbon Capture & Sequestration (CCS)

Package&Delivery

Our factory

Our Certification

Related News

Submitted successfully

We will contact you as soon as possible