G-30 Nickel Base Alloy Pipe

Hastelloy G30 Tubing is corrosion resistant alloy with excellent corrosion resistance to oxidizing environments. Hastelloy G30 Tube has been very successful as phosphoric acid heat exchanger tubing and for other process components in the fertilizer industry.The high chromium content of both of these Hastelloy G30 Pipe make them the premier choices for strong oxidizing solutions and mixed acid pickling services.

Production process of Hastelloy G30 alloy:

1. Hot rolled forming;

2. Hot extrusion molding.

Hastelloy G30 Seamless Pipes is a corrosion resistant alloy of nickel – chromium – molybdenum that is particularly appropriate for use in oxidizing acids. Hastelloy G30 Seamless Tubes is a excessive Nickel primarily based alloy which suggests best corrosion resistance over most different Nickel and Iron based totally alloys in phosphoric acids as properly as many complicated environments containing incredibly oxidising acids such as nitric, hydrofluoric and sulphuric. Hastelloy G30 Welded Pipes has proper ductility, excessive corrosion resistance even in the welded condition, and prevents corrosion through nitric, phosphoric and sulphuric acids. Hastelloy G30 Welded Tubes is a nickel – chromium – iron cloth exceptionally resistant to "wet process" phosphoric acid. Hastelloy UNS N06030 Pipes are recognised during the chemical technique enterprise as the premier corrosion resistant materials.

Product Parameter

| SIZE | 15 NB to 150 NB IN |

| TYPE | Seamless / ERW / Welded / Fabricated / Hollow / LSAW Pipes |

| WALL THICKNESS | 035" –.095′, (special wall thicknesses available) |

| SCHEDULE | SCH5, SCH10, SCH40, STD, SCH80, SCH160 |

| FINISH | Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF |

| FORM | Round, Square, Rectangular, Hydraulic, Straight or ‘U’ bent Tubes Etc |

| LENGTH | Single Random, Double Random & Cut Length. |

| END | Plain End, Beveled End, Treaded. |

| SURFACE FINISH | 1/2 inch through 1" tubing is mechanically polished with an inner diameter (ID) of 20 Ra µ-inch (0.5 µm) Outer diameter (OD) of 32 µ-inch (0.8 µm). 1-1/2 and 2 inch Alloy G30/ G35 tubing is available with a sanitary finish that is better than traditional commercial grade tube finish, and suitable for applications in sanitary/ high purity hygienic industries. 3 inch Alloy G30/ G35 tubing is available with a mill finish ID and OD. |

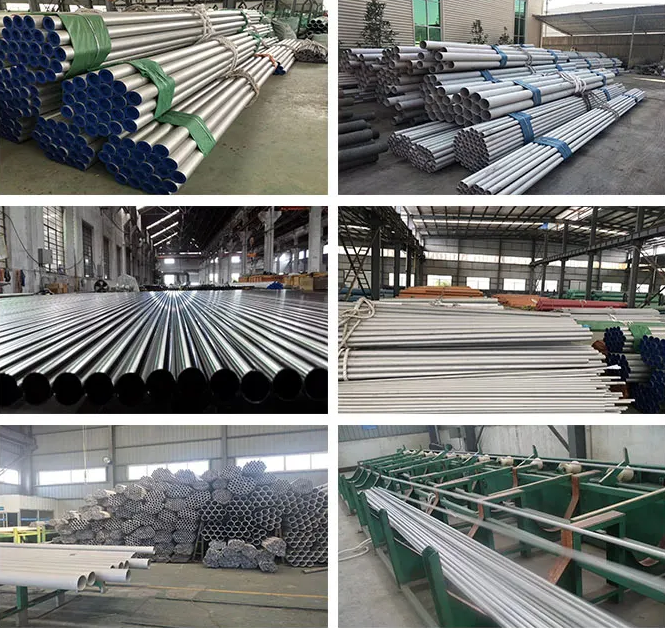

Product Display

Application

Wire wound resistors.

Bimetal contacts.

Electric and electronic applications.

Marine engineering.

Chemical and hydrocarbon processing equipment.

Gasoline and freshwater tanks.

Crude petroleum stills.

De-aerating heaters.

Package&Delivery

Workshop Show

About us

Derun Metal Co., Ltd. since its establishment, in all walks of life colleagues and customers care and support, steady progress, has developed into a processing, sales agent as one of the integrated enterprise. We place orders directly to domestic and foreign steel mills, and maintain good cooperative relations with major steel mills all year round. The company's economic strength is strong, now for domestic and foreign major steel mills direct selling enterprises. Welcome new and old customers to the factory to discuss cooperation, let's toast together, win-win cooperation.

Our Certification

Related News

Submitted successfully

We will contact you as soon as possible