SS 316 – Austenitic Stainless Steel Grade

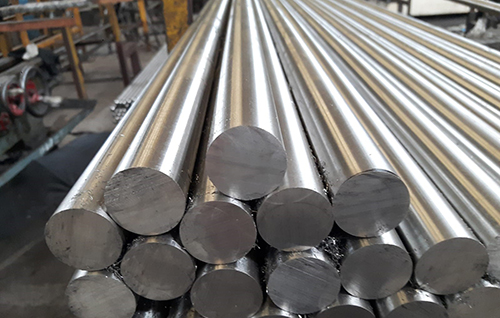

Austenitic Stainless Steel

Austenitic stainless steel is a specific type of stainless steel alloy. Stainless steels may be classified by their crystalline structure into four main types: austenitic, ferritic, martensitic and duplex stainless steel.

This austenite crystalline structure is achieved by sufficient additions of the austenite stabilizing elements nickel, manganese and nitrogen. Due to their crystalline structure, austenitic steels are not hardenable by heat treatment and are essentially non-magnetic.

There are two subgroups of austenitic stainless steel. 300 series stainless steels achieve their austenitic structure primarily by a nickel addition while 200 series stainless steels substitute manganese and nitrogen for nickel, though there is still a small nickel content.

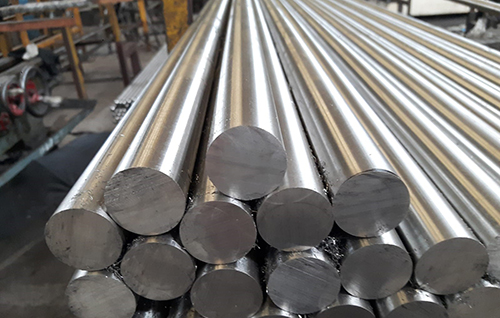

300 series stainless steels are the larger subgroup. The most common austenitic stainless steel and most common of all stainless steel is Type SS 304, also known as 18/8 or A2.

Type SS 316 is the next most common austenitic stainless steel. Some 300 series, such as Type SS 316, also contain some molybdenum to promote resistance to acids and increase resistance to localized attack (e.g. pitting and crevice corrosion). The higher nitrogen addition in 200 series gives them higher mechanical strength than 300 series

Other notable austenitic stainless steels are Type 309 and 310, which are utilized in high temperature applications greater than 800°C.

Alloy 20 (Carpenter 20) is an austenitic stainless steel possessing excellent resistance to hot sulfuric acid and many other aggressive environments which would readily attack type 316 stainless.

This alloy exhibits superior resistance to stress-corrosion cracking in boiling 20–40% sulfuric acid. Alloy 20 has excellent mechanical properties and the presence of niobium in the alloy minimizes the precipitation of carbides during welding.

Austenitic stainless steel can be tested by nondestructive testing using the dye penetrant inspection method but not the magnetic particle inspection method. Eddy-current testing may also be used.

Related News

Submitted successfully

We will contact you as soon as possible