Internal Stainless steel forged thread flangeThe threaded flanges are connected to the ends of the two pipes, and each flange is installed.

Contact Now

Basic Info.Model NO.Steel SheetSpecial UseHigh-strength Steel PlateStockStockMOQ1tonSampleAvailableSmall OrderIt′s OkMaterialStock/ProductionServiceOEM/ODMOur ForwarderFocusing on Steel IndustryOur PackerMore Than Ten Years ExperienceOur SalesmanAbout Five Years ExperienceOur ComapnyAbout Five Years ExperienceOur AdvantageOne-Stop ServiceTransport PackageStandard Export Seaworthy Package, or as RequiredSpecificationThickness: 12mmOriginShanghaiHS Code7207225409Production Capacity4000tons/MonthProduct DescriptionProduct DetailsWidth1500-4050mmWall thickness8mm-300mmLength3000MM-15000MMInternati

Contact Now

ApplicationThe softened and annealed low carbon alloy 625 is widely used in the chemical process industry.

Contact Now

Stainless Steel 316 TubeStainless Steel 316 Tube is a grade of stainless metal produced in accordance with the American ASTM standard. Stainless Steel 316 Tube is equal to our country's 0Cr17Ni12Mo2 stainless steel. Japan additionally quoted the American title and referred to as it: SUS316.Stainless Steel 316 Tube has right plasticity, toughness, bloodless denaturation, and welding system performance. Stainless Steel 316 Tube has exact excessive temperature power and 316L has terrible excessive temperature performance, however its corrosion resistance is higher than 316.

Contact Now

Decorations, constructions, food industry, etc..Stainless steel pipe can be made according to the customers requirements.Product Parameter:NameWelded Steel PipesSizeOuter diameter :6 mm - 630mmThickness : 1- 40mmLength : 2000/2440/3000/5800/6000mm etcOrdinary DimensionDN6 /DN8/DN15/DN25/DN32/DN40/DN50/DN80/DN100/DN200/DN500 etcMaterial Series201 / 202 / 304 /310/310S/316/316L/409/409L/410/410S /420/430 etcTechniquePre-galvanized / Hot-dipped galvanized / Hang-planting galvanizationSteel GradeQ195, Q235A-B, Q345A-E, 20#, 10#,16Mn, ASTM A36,ASTM A500, ASTM A53, ASTM 106, SS400, St37, St52,

Contact Now

2205 chrome steel pipe has immoderate pressure resistance, proper toughness, pipe phase prolonged interface less, corrosion resistance, flat surface, long provider lifestyles and one of a kind inclinations, chrome steel pipe length help customization.This form of metal is extensively utilized in chemical organisation, transportation of massive chemical packing containers, herbal fuel and oil organisation, paper enterprise, environmental pollutants manipulate device and so forth.Product Parameter:Product NameStainless steel welded pipeStandardASTM AISI DIN, EN, GB, JISSteel Grade200 Series: 201

Contact Now

304L stainless steel is also known as environmentally friendly low-carbon stainless steel. As a low-carbon 304 stainless steel, its corrosion resistance is similar to that of 304 in general use scenarios, but 304L stainless steel can also maintain good resistance after welding or stress relief. It has excellent corrosion resistance and can maintain excellent corrosion resistance without heat treatment. The operating temperature range can reach -196℃-800℃.

Contact Now

321 stainless steel is a Ni-Cr-Mo type austenitic stainless steel, its properties are very similar to 304, but due to the addition of metal titanium, it has better resistance to grain boundary corrosion and high temperature strength. Due to the addition of metallic titanium, it effectively controls the formation of chromium carbide. Ti in 21 stainless steel exists as a stabilizing element, but it is also a heat-strength steel, which is much better than 316L in high temperature.

Contact Now

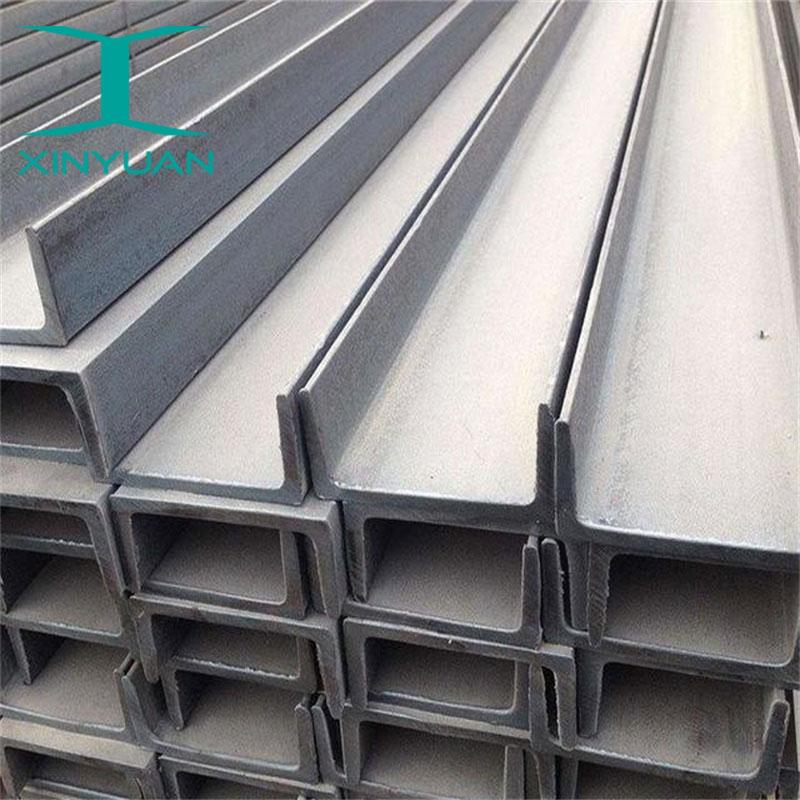

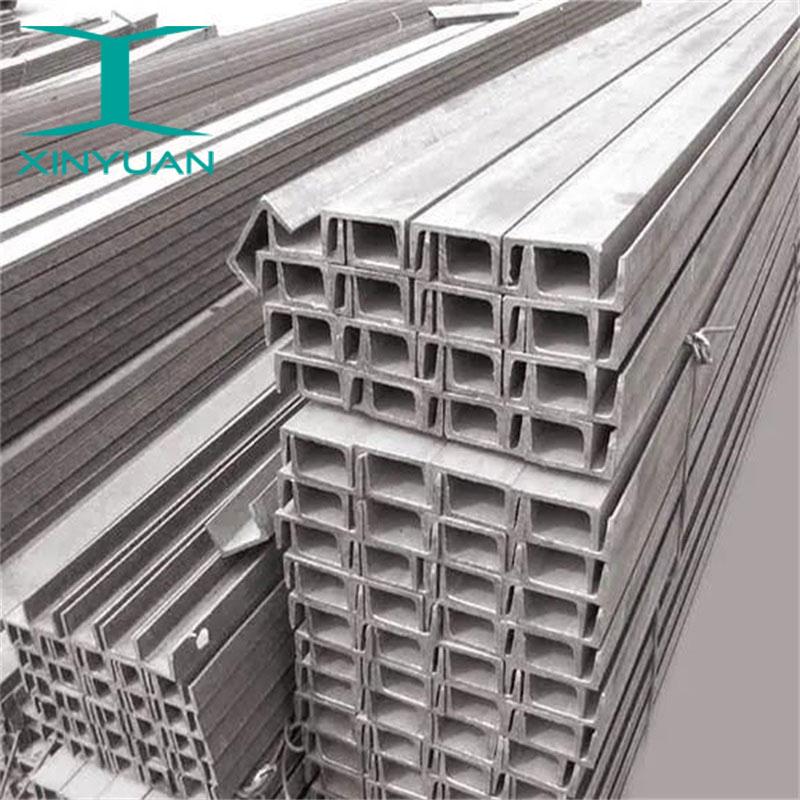

Unlike mild steel the chemistry of stainless steels means the processes and methods for protecting and finishing 316 Grade Stainless Steel are vastly different to mild steels. Most surface finishes for stainless steel will be mechanically (Polishing) or chemically (Passivating) applied. The correct surface finish will have substantial impacts on the performance and appearance of your stainless steel. Product Parameter:Product NameStainless Steel ChannelSize50*37*4.5 - 400*104*14.5SurfaceBA, 2B, 2D, 4K, 6K, 8K, NO.4, HL, SB, EmbossedThinckness4.5mm-14.5mmWidthness

Contact Now

304L stainless steel is a variant of the lower carbon 304 stainless steel, used for welding occasions.

Contact Now

Stainless steel coil: Material: SUS201, 202, 304, 316L, 316Ti, 321, 304L, 441, 444, 436, 439, 430, 409L, 410S, 309S, 310S, 904L, 2205, 2507, etc. Thickness: 0.3-16.0mm, width 1 meter, 1.22 meters, 1.5 meters, 1.8 meters, 2 meters, non-standard can be customized. Stainless steel properties:As a widely used steel, has good corrosion resistance, heat resistance, low temperature strength and mechanical properties; Stamping, bending and other hot workability, no heat treatment hardening phenomenon (use temperature -196℃~800℃). Household products (cl

Contact Now

Stainless steel coil is one of the most popular raw materials in construction and manufacturing. Because of its unique mechanical and physical properties, stainless steel coils have been widely used in the production of kitchen appliances and industrial equipment. They are rugged, corrosion resistant, lightweight and require low maintenance. In addition, they are flexible and easy to meet the requirements of a series of design standards. In industry (especially in manufacturing), many grades of stainless steel coils can be found, each with different performance and availability.

Contact Now

Products DescriptionStainless steel is notable for its corrosion resistance, and it is widely used for food handling and cutlery among many other applications.CommodityHot and cold rolled stainless steel coil/sheet/pipe/stripGrade201,202,301,304,304j1,304l,321,309s,310s,2205,409l,410,410s,420,420j1,420j2,430,439,409l,443,444,etcStandardISO,JIS,ASTM,AS EN,GBsurfaceNO.1 /NO.2D /NO.2B /BA /NO.3 /NO.4 /NO.240 /NO.320 /NO.400 /HL /NO.7/ NO.8,etcThickness0.2-100mm(common:0.2-0.5mm)(Precision Stainless Steel Strip:0.05mm)Width100-2000mmSpecification1000*2000/L,1219*2438/L,1500*3000/L,1500*6000/L

Contact Now

Stainless steel coil is one of the most popular raw materials in construction and manufacturing. Because of its unique mechanical and physical properties, stainless steel coils have been widely used in the production of kitchen appliances and industrial equipment. They are rugged, corrosion resistant, lightweight and require low maintenance. In addition, they are flexible and easy to meet the requirements of a series of design standards. In industry (especially in manufacturing), many grades of stainless steel coils can be found, each with different performance and availability.

Contact Now

321 Stainless Steel Coil321 Stainless Steel Coil and sheet is section of the austenitic household of stainless steel. 321 Stainless Steel Coil is essentially a 304 grade containing a stabilizer of titanium. 321 Stainless Steel Coil is a exact desire for functions the place warmth is an issue. 321 Stainless Steel Coil can be used in purposes up to 900 stages Celsius the place 304 is typically used up to five hundred levels Celsius. 321 Stainless Steel Coil has brilliant forming and welding characteristics.

Contact Now

304 Stainless Steel CoilWith its chromium-nickel content material and low carbon, 304 Stainless Steel Coil is the most versatile and broadly used of the austenitic stainless steels. Occasionally referred to as "18-8," 304 Stainless Steel Coil has higher corrosion resistance than Type 301 or 302 and provides high-quality drawing and forming characteristics.

Contact Now

Superior creep and stress rupture properties are demonstrated by SS 321 Hex Bars in comparison with Stainless Steel 304 Hex Bars and, more specifically, Stainless Steel 304L Hex Bars, which may be considered for use in environments prone to sensitization and intergranular corrosion.

Contact Now

Incoloy 840 has the characteristics of simple structure, high mechanical strength, high thermal efficiency, safety and reliability, easy installation, long service life, etc., widely used in all kinds of water tank, oil tank, acid and alkali tank, fusible metal melting furnace, air heating furnace, drying furnace, drying oven/oven, oven and hot press die device.

Contact Now

The Incoloy 800HT is resistant to many corrosive media. Its high nickel content makes it have good resistance to stress corrosion cracking under water-based corrosion conditions. High chromium content makes it have better resistance to spot corrosion and crevice corrosion cracking. The alloy has good resistance to nitric acid and organic acid, but limited resistance to sulfuric acid and hydrochloric acid. Excellent corrosion resistance in oxidizing and non-oxidizing salts, except for the possibility of point corrosion in halides.

Contact Now

The machinability of grade 202 stainless steel produces long, gummy chips. Machining can also be performed in the annealed condition. For heat treatment, the material has to be soaked at 1038°C (1900°F) for 30 min and cooled below 16°C (60°F) for full martensite transformation. The material can be welded by common fusion and resistance methods; however, this steel should not be joined using oxyacetylene welding method. The recommended filler metal is AWS E/ER630. Forging can be done by pre-soaking for 1 h at 1177°C (2150°F).

Contact Now

410 stainless Hexale bar: 410 stainless steel is a stainless steel grade produced according to ASTM standard of America, equivalent to 1Cr13 stainless steel of our country, S41000 (American AISI, ASTM).Product Parameter:StandardASTM A479,ASTM A276,ASTM A484, ASTM A582,ASME SA276, ASME SA484, GB/T1220, GB4226, etc.Material301, 304, 304L, 309S, 321, 316, 316L, 317, 317L, 310S, 201,202321, 329, 347, 347H 201, 202, 410, 420, 430, S20100, S20200, S30100, S30400, S30403, S30908, S31008, S31600, S31635, etc.SpecificationsRound barDiameter:0.1~500mmAngle barSize: 0.5mm*4mm*4mm~20mm*400mm*400mmFlat bar

Contact Now

This kind of material with high formability, many is given priority to with brocade alloy are more likely to be welded.

Contact Now

Many industry will use 420 stainless steel rods, this kind of material with metallic luster, so choose the material production tools or equipment products, prominent on the appearance, the surface of the plate is very smooth, can also be customized according to the actual demand for processing, high plasticity, in the process of installation can tolerate acid and alkaline substances.Product Parameter:ProductStainless Steel BarBase materialstainless steel 200 series,300 series,400 seriesThickness0.40-5.00mmDiameter6-273mmstandardASTM A554/DIN/EN10296-2/JIS G3446,A269,A249,A270,EN10204 3.1Qualit

Contact Now

OEM ODM customized hot sale precision stainless steel threaded flangeItemDescriptionBasic InformationMaterial GradeWP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etcSize1/2" to 48" Sch 5S to XXSStandardASTM A403 etc .Process MethodForged / CastingIndustry & AdvantageApplicationa) Connect pipesAdvantagea) High technology ; good surface ; high quality etcTerms & ConditionsPrice ItemFOB , CFR , CIF or as negotiationPaymentT / T , LC or as negotiationDelivery Ti

Contact Now