317l bars & rods is providing better creep, pressure to rupture, high tensile energy, and weldability. due to first-rate yield electricity, it has great thermal stability that can be utilized in accelerated temperature service. it has advanced corrosion resistance to corrosive acids together with acetic, formic, sulfurous, citric, and tartaric acid.

Contact Now

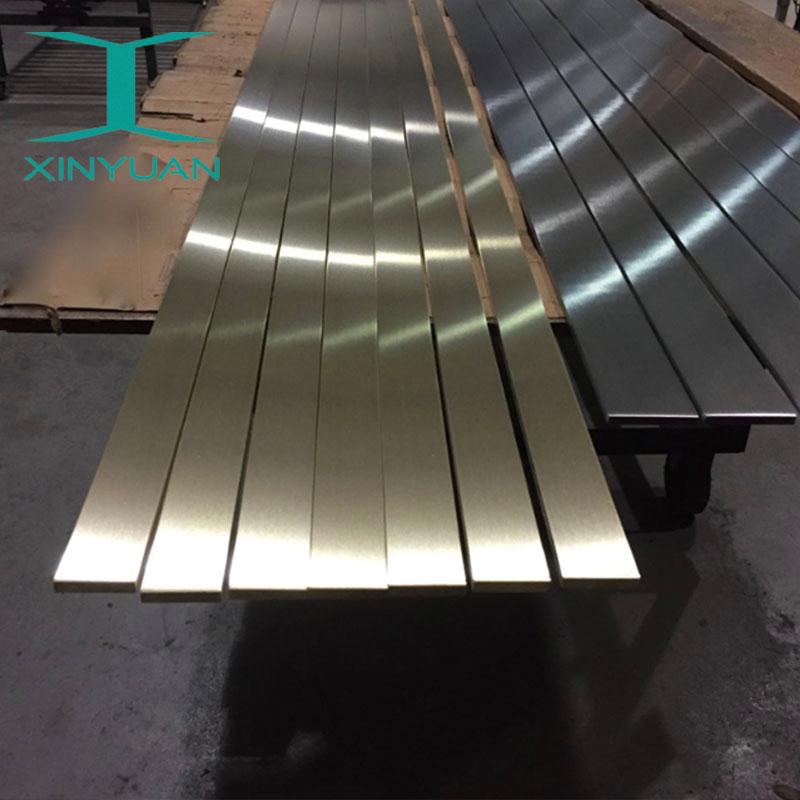

Product Name SS 304 304L 310S 316 316L 321 309S 904L 2205 Stainless Steel Strip Manufacturer Stainless Steel CoilSteel typeAISI 630, AK Steel 17-4PH, UNS 17400JIS SUS630 X5CrNiCU17-04EN 1.4542StandardASTM A564Thickness0.04-10mmWidth5-2000mmFinishingSolution treated + age hardening heat treated ( H900, H1150, H1150D, H1150M, H1075, H1025 etc )Feature of 630High Tensile strength, high hardness after heat treated.Mechanical propertyT.S. (Rm): 1015Mpa, Y.S.

Contact Now

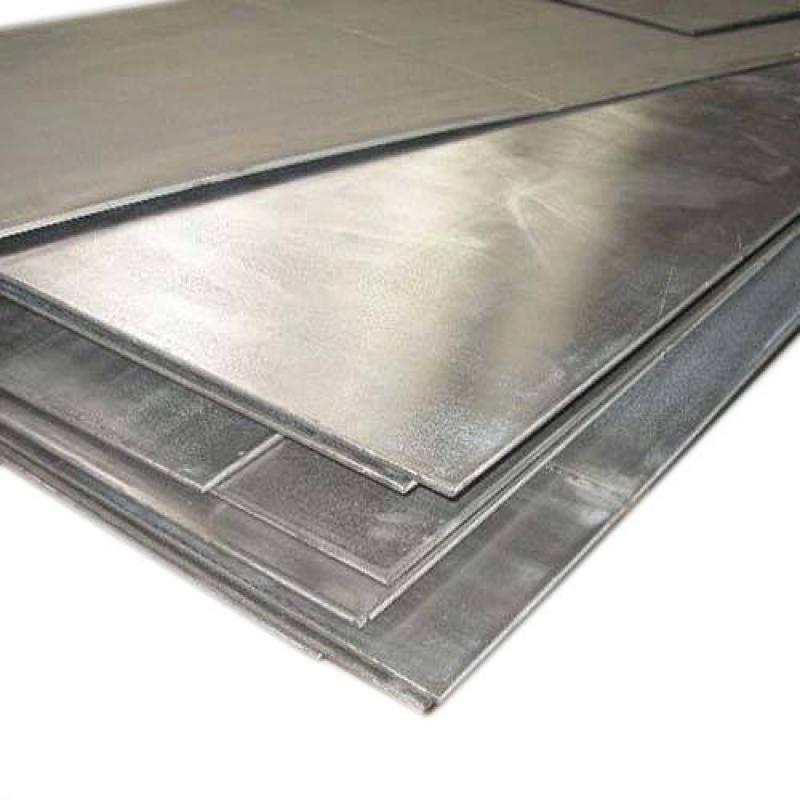

Features and Benefits• Made from silver-coloured 304S15 stainless steel• Length of 300 mm• Width of 300 mm• Thickness of 1 mm• Density of 8 g/cm³• Hardness 92 HB• Thermal conductivity of 16.2 W/m at +100°C• Tensile strength of 520 Mpa• RoHS (Restriction of Hazardous Substances) compliant• Meets standards BS1449 pt 2 and BSEN 10088-2 for steel plate, sheet and strip• Comes without adhesive backingSpecificationsAttributeValueLength300mmMaterial304S15 Stainless SteelFormSolidWidth300mmThickness1mmDensity8g/cm³Hardness92 HBColourSilverThermal Conductivity16.2 W/m at 100°cAdhesive BackingNoTensile

Contact Now

Alloy A286 features high strength, oxidation resistance, and corrosion resistance at continuously high temperatures. A286 alloys are heat treatable to achieve a wide variety of grain structures and tensile properties. This grade of A286 is annealed and aged. Applications for Alloy A286 include jet engine components, superchargers, turbine wheels and blades, fasteners, springs, and general high-stress components in petrochemical, aerospace, and oil patch industries.DetailsA286 is an iron-nickel-chromium alloy with additions of molybdenum and titanium.

Contact Now

1) Test methods.① Tensile test method. Commonly used standard test methods are GB/T228-87, JISZ2201, JISZ2241, ASTMA370, ГОСТ1497, BS18, DIN50145, etc..② Bending test method. Commonly used standard test methods are GB/T232-88, JISZ2204, JISZ2248, ASTME290, ГОСТ14019, DIN50111, etc.(2) performance indicators: the test items to assess the performance of angle steel are mainly tensile test and bending test.

Contact Now

201 stainless steel tube has: acid resistance, alkali resistance, high density without pinhole and other characteristics, is the production of a variety of watchcase, watchband cover quality materials. 201 stainless steel pipe can be used in decorative pipe, industrial pipe, some shallow tensile products used in. 201 Stainless steel tube for physical properties1. Elongation :60 to 80%2. Tensile stiffness :100,000 to 180,000 psi3. Elastic modulus :29,000,000 psi4.

Contact Now

310 Stainless Steel Angles are manufactured using high-grade steel, which contains chromium, nickel, and additional molybdenum, niobium, titanium, and nitrogen. These additional elements offer excellent tensile strength, high surface finish, outstanding corrosion & oxidation resistance, and good mechanical properties.

Contact Now

Type 309 is an austenitic chromium nickel stainless steel (.08% max carbon).Type 309is employed for parts requiring both corrosion and heat resistance and oxidation resistance up to 2000oF. Strength at elevated temperatures is similar to that of 18-8 Stainless Steels.This alloy posses excellent resistance to oxidation as well as high tensile and creep strengths at elevated temperatures.

Contact Now

2507 dual-phase steel density: 8.03g/cm3, melting point: 1300-1390 ℃, magnetic: noneHeat treatment: heat preservation between 1000-1052℃ for 1-2 hours, rapid air cooling or water cooling.Mechanical properties: tensile strength: σb≥795Mpa, yield strength σb≥550Mpa: elongation: δ≥15%, hardness ≤310 (HB)Product Parameter:ItemStandardMaterialStainless SteelASTM201, 202, 301, 304, 304L, 304N, XM21, 304LN, 305, 309S, 310S, 316, 316Ti, 316L, 316N, 316LN, 317, 317L, 321, 347, 329,405, 409, 430, 434, 444, 403, 410, 420, 440A, etc.EN1.4372, 1.4373, 1.4319, 1.4301, 1.4306, 1.4315, 1.4303, 1.4833, 1.4845,

Contact Now

Stainless Steel Bar 321 316Stainless steel bar provides excellent tensile strength, high resistance to rust, and high fabrication ability. stainless steel bar is a highly cost-effective and versatile material.

Contact Now

Heat treatment can’t be used to harden this metal. In order to achieve tensile strength and hardness, cold working must be done. When cold working is used, slight magnetism may occur. It is very common for 304 steel to be used for parts that require grinding, welding, polishing and machining, along with corrosion resistance. Because of its ability to handle corrosive environments, it is considered a general all-purpose grade of steel. It is commonly used in chemical industries and for cryogenic services.

Contact Now

347h stainless steel bar is a form of stainless-steel alloy that belongs to the austenitic circle of relatives. it includes high stages of chromium, nickel, and small amounts of niobium (columbium) to enhance its resistance to corrosion and high-temperature environments.The "h" in 347h represents the high carbon content material, which affords advanced excessive-temperature power. this stainless steel grade has brilliant mechanical properties, inclusive of high tensile and yield strength.

Contact Now

Stainless Steel 317 Square Bars & Rods have excellent yield strength and tensile strength, which is suitable for cold working and annealed condition appliance. It has nickel and low carbon content to provide high formability and excellent corrosion resistance to alkaline compounds. SS 317 Bars & Rods is austenitic stainless steel non-magnetic in nature, less conductivity to electricity, and less brittle at low temperature.

Contact Now

Stainless steel 301 Square Bar include 17% chromium and 7% nickel, which give excessive tensile strength as much as 1800mpa. these ss 301 bars are in particular used in plane, rail vehicle additives, and architectural structures.

Contact Now

Type 201 Stainless Steel is an austenitic chromium-nickel-manganese stainless steel which was developed to conserve nickel. Type 201 is a lower cost alternative to conventional Cr-Ni stainless steels such as 301 and 304. Nickel is replaced by additions of manganese and nitrogen. It is non-hardenable by thermal treatment, but may be cold worked to high tensile strengths. Type 201 is essentially nonmagnetic in the annealed condition and becomes magnetic when cold worked.

Contact Now

Monel 400 PlateMonel 400 Plate is a copper-nickel base alloy plate. Along with these, it is traced with the quantity of manganese, silicon, and carbon content. These Monel 400 Plates have proper ductility and facilitate most suitable resistance to a extensive vary of corrosive circumstances. These plates show off terrific resistance to alkaline and acidic environment. However, it posses extraordinary thermal conductivity in annealed conditions. This grade of plates consists of excessive tensile energy and toughness.

Contact Now

304 Stainless Steel Hexagon Bar Hardness and tensile strength can be increased by cold working, but modified by lowered carbon content providing good resistance to corrosion in welded construction where subsequent heat treatment is not practical.Product Parameter:StandardASTM A479,ASTM A276,ASTM A484, ASTM A582,ASME SA276, ASME SA484, GB/T1220, GB4226, etc.Material301, 304, 304L, 309S, 321, 316, 316L, 317, 317L, 310S, 201,202321, 329, 347, 347H 201, 202, 410, 420, 430, S20100, S20200, S30100, S30400, S30403, S30908, S31008, S31600, S31635, etc.SpecificationsRound barDiameter:0.1~500mmAngl

Contact Now

201 stainless steel bar is a type of stainless steel that contains low nickel content and higher manganese content. It is a cost-effective option for applications that require corrosion resistance and moderate strength.Some key features of 201 stainless steel bar include:Good corrosion resistance: It offers resistance to atmospheric corrosion, mild acids, and alkalis.Moderate strength: It has lower yield strength and tensile strength compared to other stainless steel grades, such as 304 or 316.201 stainless steel bar is commonly used in various industries such as construction, automotive

Contact Now

Stainless Steel 304L FlangesStainless Steel 304L Flanges has a minimum of 18% chromium and 8% nickel. Type SS 304L Blind FLanges(BLRF) has a Carbon maximum is 0.035. Stainless Steel 304L Pipe Flanges is the standard "18/8 stainless" that is commonly found in Industrial Flanges and applications. 304L Stainless Steel Blind Flange is the most versatile and widely used alloy flange. The ultimate tensile strength (UTS) of SS 304L Spectacle Blind Flange is roughly~515 Mpa, 304L having a 0.2% yield strength of~205Mpa.

Contact Now

The Stainless Steel 347 Angle/ Channels offers are excellent services in high temperature, high corrosion resistance, excellent pitting resistance, and great stress crack corrosion properties. Other mechanical properties that can be found in this grade are excellent machining, high strength, great tensile strength, high yield strength, and the more significant low creep properties. All these features and properties make these Angle/ Channels more suitable to use in various complex industrial applications and operations.Product Parameter:NameStainless Steel angle barStandardAS

Contact Now

Section shrinkage ψ(%):134 degrees, aging ≥ 61Density melting point for Young's modulus and Poisson's ratio, yield strength, tensile strength, elongationProduct Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turb

Contact Now

304 Stainless Steel Wire304 Stainless Steel Wire is a universal motive stainless alloy usually composed of 18% chromium and 8% nickel. 304 Stainless Steel Wire is the most broadly used stainless spring wire due to the fact of its excessive corrosion resistance residences and correct tensile strength. For spring purposes 304 Stainless Steel Wire is normally furnished in the bloodless drawn condition. 304 Stainless Steel Wire has right power at average temperatures. If proper handled after forming they will set much less than most different spring substances at temperatures up to 500ºF.

Contact Now

super duplex 2507 round bar is an alloy which has been designed for applications that demand exceptional tensile strength and superior resistance to corrosion as well.Product Parameter:Stainless Steel barMaterial200 series: 201,202,202Cu,204Cu,300 series: 301, 303/Cu, 304/L/H, 304Cu, 305, 309/S, 310/S, 316/L/H/Ti, 321/H, 347/H, 330,400 series: 409/L, 410, 416/F, 420/F, 430, 431, 440C, 441, 444, 446,600 series: 13-8ph, 15-5ph, 17-4ph, 17-7ph(630,631), 660A/B/C/D,Duplex: 2205(UNSS31803/S32205), 2507(UNSS32750), UNSS32760, 2304, LDX2101.

Contact Now

Stainless steel elbow is suitable for all kinds of water quality, in addition to disinfection and sterilization, do not need to control the water quality, at the same time, there is no corrosion and excessive exudate, can keep the water pure health, put an end to secondary pollution, can withstand up to 30 meters per second high water impact.

Contact Now