Alloy K-500 (UNS N05500) is a nickel-copper alloy.

Contact Now

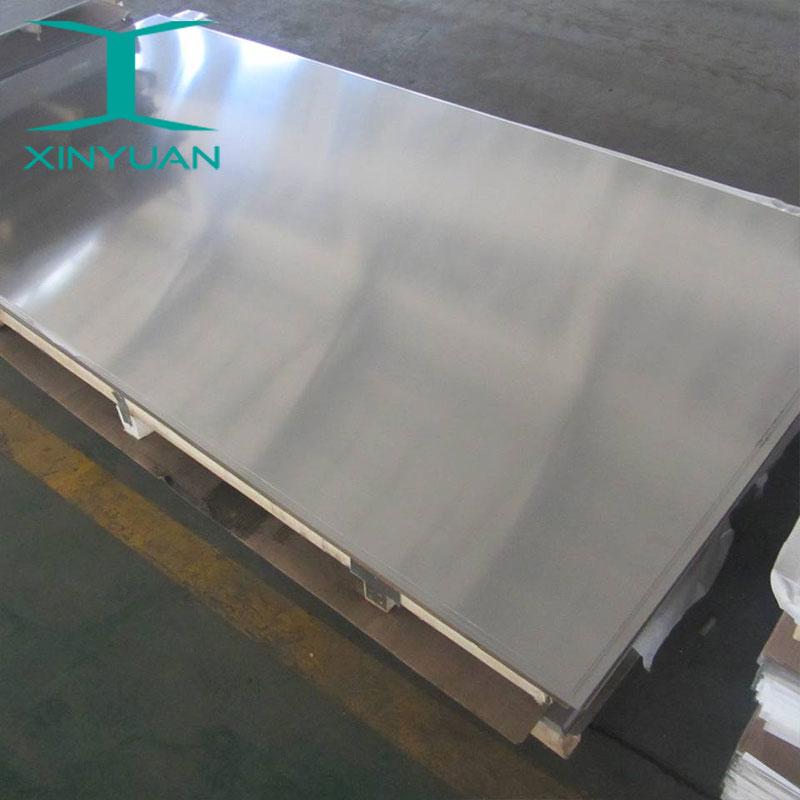

Manufacturer Alloy 330 Incoloy 330 nickel alloy sheet/plate/coilTypeNickel Alloy Sheet/PlateThickness0.8-36mmLength3000mm, 5800mm, 6000mm,etcWidth1000mm,1500mm,2000mm,etcStandardASTM,AISI,JIS,DIN,ENApplicationConstruction,Ship,Boiler,Machinery,etcCertificationISO,SGS,TUVTechniqueCold Rolled/Hot RolledEdgeMill Edge/ Silt EdgeGradeHastelloy: Hastelloy B/ -2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g;etcInconel 600/601/602CA/617/625/713/718/738/X-750;ETCIncoloy: Incoloy 800/800H/800HT/825/925/926;etcGH: GH2132,GH3030,GH3039,GH3128,GH4180,GH3044,etcMonel: Monel 400/K500/R405,etcNitronic 40/50/60/7

Contact Now

600 alloy (UNS NO6600) The alloy is widely used in the chemical industry for its strength and corrosion resistance. Applications include heaters, stills, bubbles and condensers for fatty acid processing; Evaporator tubes, segments and spalling pans for the manufacture of sodium sulfide; And equipment for processing plants.

Contact Now

Nickel - base corrosion - resistant alloys mostly have austenite structure. There are intermetallic phases and metal carbonitrides in austenite matrix and grain boundary of alloy under solution and aging treatment. Product Parameter:Product NameChina Factory Supplier Nickel Based Alloy Steel Astm B444 Uns N06625 Inconel 625 Din2.4856 Alloy 625 Steel Pipe TubeStandardGB,AISI,ASTM,DIN,EN,JISGradeStainless steel 304 / 304L / 310S / 316L / 316Ti / 316LN / 317L / 904L / 2205 / 2507 / 32760 / 253MA / 254SMo / XM-19 / S31803 /S32750 / S32205 / F50 / F60 / F55 / F60 / F61 / F65 e

Contact Now

Nickel Base Alloy Plate It should be noted that active metals cannot be used in fluorine-containing environment (for example, Hastelloy C2000, NICU alloy, etc. can be used in hydrofluoric acid environment).Nickel Base Alloy is Active metals ,it also have good corrosion resistance, and the typical representative is Ti; Zr; TA et al; The most typical one is Ti; Titanium material has a wide range of applications, mainly used in some corrosion environments that stainless steel can not adapt to.

Contact Now

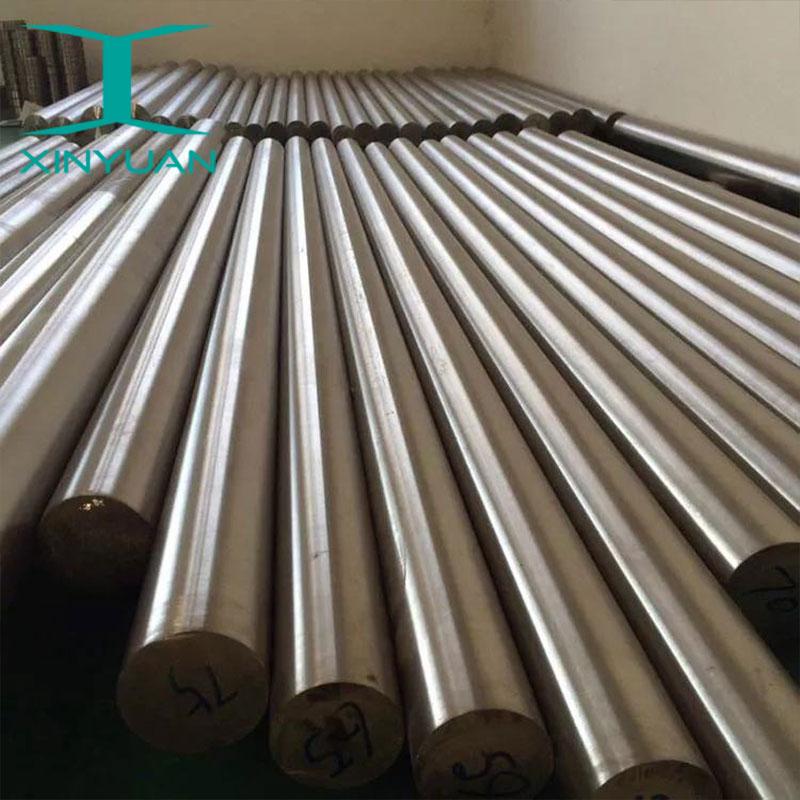

Incoloy 330 is a nickel-ferrichrome austenite alloy.specifically designed for antioxidant and carburizing effects in high-temperature environments.Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines

Contact Now

Alloys Incoloy 800H and Incoloy 800HT are iron-nickel-chromium solid solution strengthened alloys with a nominal chemical composition of 42% iron, 34% nickel, and 22% chromium. These two grades are variations of the base grade 800 and are referred to by the tradenames Incoloy 800H and Incoloy 800HT and the universal designation UNS N08810 and N08811, respectively.

Contact Now

Type 301 is an austenitic chromium-nickel stainless steel that is available in the annealed and cold worked conditions. In the annealed condition, Type 301 offers the highest level of stretch formability of any stainless steel and in the heavily cold worked condition offers the highest strength level of any 300 series stainless steel. Type 301 is non-magnetic in the annealed condition but becomes magnetic as a result of cold working.Type 301 is corrosion resistant in many environments, but the corrosion properties are less than that of 304/304L stainless steel.

Contact Now

Inconel nickel base alloy 600 625 706 725 seamless hastelloy pipeProduct Parameter:Product NameChina Factory Supplier Nickel Based Alloy Steel Astm B444 Uns N06625 Inconel 625 Din2.4856 Alloy 625 Steel Pipe TubeStandardGB,AISI,ASTM,DIN,EN,JISGradeStainless steel 304 / 304L / 310S / 316L / 316Ti / 316LN / 317L / 904L / 2205 / 2507 / 32760 / 253MA / 254SMo / XM-19 / S31803 /S32750 / S32205 / F50 / F60 / F55 / F60 / F61 / F65 etcMonel 400 / Monel K-500Inconel 600 / Inconel 601 / Inconel 625 / Inconel 617 / Inconel 690 / Inconel 718 / Inconel X-750Incoloy A-286 / Incoloy 800 / Incoloy 800H / Incol

Contact Now

904L Stainless Steel BarNickel base corrosion resistant alloys have austenite structure. In the state of solid solution and aging treatment, there are intermetallic phases and metal carbonitrides on the austenite matrix and grain boundary of the alloy.Ni Mo alloy is mainly used under the condition of reducing medium corrosion.

Contact Now

Incoloy 825 Nickel Base Alloy Pipe the organism is mainly used in heat treatment equipment, resistance alloy tube type heater and covering device, chemical such as petroleum processing equipment.Product Parameter:Product NameChina Factory Supplier Nickel Based Alloy Steel Astm B444 Uns N06625 Inconel 625 Din2.4856 Alloy 625 Steel Pipe TubeStandardGB,AISI,ASTM,DIN,EN,JISGradeStainless steel 304 / 304L / 310S / 316L / 316Ti / 316LN / 317L / 904L / 2205 / 2507 / 32760 / 253MA / 254SMo / XM-19 / S31803 /S32750 / S32205 / F50 / F60 / F55 / F60 / F61 / F65 etcMonel 400 / Monel K-500Inconel

Contact Now

Incoloy 800H Nickel Base Alloy Pipe Application:National defense, astronautics, transportation, equipment manufacture, shipping, petroleum, nuclear power industry, oil and gas industry, and chemical industry etc.Product Parameter:Product NameChina Factory Supplier Nickel Based Alloy Steel Astm B444 Uns N06625 Inconel 625 Din2.4856 Alloy 625 Steel Pipe TubeStandardGB,AISI,ASTM,DIN,EN,JISGradeStainless steel 304 / 304L / 310S / 316L / 316Ti / 316LN / 317L / 904L / 2205 / 2507 / 32760 / 253MA / 254SMo / XM-19 / S31803 /S32750 / S32205 / F50 / F60 / F55 / F60 / F61 / F65 etcMonel 400 / Monel K-500

Contact Now

This nickel based alloy produced in the form of rounds, squares, hexagons, rectangles as well as Alloy 601 Uns N06601 Cold Finished Bar apart from cold- worked wire, have been covered in the ASTM B166 specification.

Contact Now

Inconel 625 Nickel Base Alloy PipeInconel 625 demonstrates an extraordinary mixture of corrosion resistance and excessive strength. Due to the excessive nickel content, alloy 625 is immune to chloride-induced stress corrosion cracking. It additionally has appropriate resistance to pitting and crevice corrosion.

Contact Now

Incoloy 925 Nickel Base Alloy PipeThis is an age-hardenable Nickel primarily based alloy containing Iron and Chromium as primary additions, and additionally additions of Molybdenum, Copper, Titanium and Aluminum. A mixture of excessive electricity and corrosion resistance make it appropriate in functions such as valves, hangers, packers, and tubular, in bitter fuel environments. It can additionally be used for fasteners, and for pump shafts working inside marine environments.The mixture of Nickel and Chromium renders safety in each oxidizing and lowering atmospheres.

Contact Now

C276 Nickel Base Alloy Bar Hastelloy C-276 CharacterThe key elements influencing corrosion resistance of this fabric are the control of impurity S,P, gascontent O,N and key factors C,Si, and so forth.It depends on the manage of manufacturing procedure, which include thepreference of heating temperature and heat maintenance time of forging, such as the assure of forgingratio, inclusive of the assure of strong answer remedy, and so on.Product Parameter:2.Chemical compositionCSMnPSNiCrMoFeCoWVMin14.515.04.03.0Max0.010.081.00.040.03Mar

Contact Now

G-30 Nickel Base Alloy PipeHastelloy G30 Seamless Pipes is a corrosion resistant alloy of nickel – chromium – molybdenum that is particularly appropriate for use in oxidizing acids. Hastelloy G30 Seamless Tubes is a excessive Nickel primarily based alloy which suggests best corrosion resistance over most different Nickel and Iron based totally alloys in phosphoric acids as properly as many complicated environments containing incredibly oxidising acids such as nitric, hydrofluoric and sulphuric.

Contact Now

Nickel Base Alloy C276 are tremendous for warmth exchangers inside the chemical processing and nuclear industries. they’re used in steam generator tubing inside the nuclear energy industry, in excessive-temperature aircraft structures, and in oil and fuel extraction packages in which corrosion-, stress- and temperature-resistant tubing is needed.

Contact Now

Hastelloy G-35 Nickel Base Alloy PipeHastelloy G-35 is an upgraded product of G-30, it has extremely good corrosion resistance in moist manner phosphoric acid manufacturing surroundings extensively used in fertilizer manufacturing, the place it performs a long way higher than G-30 and stainless metal . It is additionally resistant to localized corrosion and chloride stress corrosion cracking in chloride-containing media. The excessive chromium content material makes it very resistant to corrosion through different oxidizing acids such as nitric acid and nitric acid-containing mixtures.

Contact Now

Alloy 718 (UNS N07718) is a high-strength, nickel-based superalloy made for long-term use in temperatures ranging from cryogenic up to 1200°F.

Contact Now

Chemical composition of Incoloy926 nickel base alloyThe content of Cr in nickel-based alloys is usually 14.0-18.0% and the content of nickel is 24.0-26.0%.

Contact Now

Copper Nickel Alloy Strip CoilCompany ProfileSince its establishment Tianjin Xinyuan Stainless Steel Co., Ltd. has been steadily seeking progress with the care and support of colleagues and customers from all walks of life, and has developed into a comprehensive enterprise integrating stainless steel material processing and sales agents.Main materials: 201, 301, 304 (0Cr18Ni9), 304L (00Cr19Ni10), 321 (1Cr18Ni9Ti), 316 (0Cr17Ni12Mo2), 316L (00Cr17Ni14Mo2), 309S (0Cr23Ni13), 310S (0Cr25Ni20), 904L (00Cr20Ni25Mo4.5Gu) 316 , 317L, 317H, 304H, (SUS304, 321, 316, 310S, etc.).

Contact Now

Inconel 600 Nickel Base Alloy PipeInconel 600 alloy is a nickel-chromium-iron-based strong answer bolstered alloy. It has accurate excessive temperature corrosion and oxidation resistance, extremely good bloodless and warm processing and welding properties, and has exceptional thermal energy and excessive plasticity under 700°C.Inconel 600 alloy can be reinforced with the aid of bloodless working, and it can also be related via resistance welding, soften welding or brazing.

Contact Now

Inconel 825 Nickel Base Alloy BarThe excessive nickel content material of Incoloy 825 offers the alloy an fantastic resistance to stress corrosion cracking. The corrosion resistance is gorgeous in a range of media, such as sulfuric, phosphoric, nitric and natural acids, alkali metals such as sodium hydroxide, potassium hydroxide and hydrochloric acid solutions.

Contact Now