slip on flange ASME B16.5 ss304L ss316L flanges plate flangeItemDescriptionBasic InformationMaterial GradeWP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etcSize1/2" to 48" Sch 5S to XXSStandardASTM A403 etc .Process MethodForged / CastingIndustry & AdvantageApplicationa) Connect pipesAdvantagea) High technology ; good surface ; high quality etcTerms & ConditionsPrice ItemFOB , CFR , CIF or as negotiationPaymentT / T , LC or as negotiationDelivery Time 30 work

Contact Now

UNS S32760 is able to compete strongly with the 6% molybdenum “super austenitic” grades in some applications, as it has fewer amounts of Mo and Ni which drive up the base cost of the material. Although, 32760 has lower amounts when compared to “6% Moly” grades it still has higher contents of Cr, Ni, and Mo when referring to other alloys, these elements improve the intergranular and pitting corrosion resistance of the material.

Contact Now

Type 201 Stainless Steel is an austenitic chromium-nickel-manganese stainless steel which was developed to conserve nickel. Type 201 is a lower cost alternative to conventional Cr-Ni stainless steels such as 301 and 304. Nickel is replaced by additions of manganese and nitrogen. It is non-hardenable by thermal treatment, but may be cold worked to high tensile strengths. Type 201 is essentially nonmagnetic in the annealed condition and becomes magnetic when cold worked.

Contact Now

317L Austenitic Stainless Steel Wire 317L Austenitic Stainless Steel Wire ’s Mechanical properties:317L mechanical properties: ys (MPA) ≥ 176, TS (MPA) ≥ 480, EL (%) ≥ 40, HV ≤ 200317L Austenitic Stainless Steel Wire 's chemical composition317L chemical composition: carbon (c) ≤ 0.030, manganese (MN) ≤ 2.00, nickel (Ni) 11.0 ~ 15.0, silicon (SI) ≤ 1.00, phosphorus (P) ≤ 0.045, sulfur (s) ≤ 0.030, chromium (CR) 18.0 ~ 20.0, molybdenum (MO) 3.0 ~ 4.0Product Parameter:Weight1000(kg/km)Diameter0.2-14mmLengthAs requirementsMaterial201,301,302,303,304,304L,316,316L,317L,321,308,308L,309,309

Contact Now

410 stainless steel wire is preheated to 400 ° f to prevent cracking, and then usually heat treated at 2000 ° F. Thanks to various heat treatments, 410 stainless steel has many characteristics. Our 410 stainless steel can be used under a variety of conditions, including condition a, condition h, condition 2 and condition 3. One of the most common oil replenishment conditions is the QDT of each NACE.

Contact Now

316L Super Austenitic Stainless Steel316L Super Austenitic Stainless Steel Scope of application:Corrosion resistance, atmospheric corrosion resistance and high temperature strength are particularly good, which can be used in harsh conditions; Excellent work hardening (non-magnetic).

Contact Now

Stainless Steel 410 is an austenitic stainless steel that combines excellent high temperature properties with good ductility and weldability. It is typically used for elevated temperature applications as its high chromium and nickel content provide solid corrosion resistance, excellent resistance to oxidation, and superior strength in temperatures up to 2100°F.

Contact Now

Stainless steel is available in many varieties, each of which suits varying applications. Some key properties that make 316 stainless steel the optimal choice for use in structural beams include its:Corrosion resistance.316 stainless steel is well-suited for building structures in marine or moist environments.

Contact Now

Application is very wide, below 980 ℃ has sufficient strength and corrosion resistance and oxidation resistance.1.Manufacture of springs and bolts working under high temperature; rotor blades, impellers and other structural parts of gas turbines;2. Thrust chamber on rocket engines;3. Thrust reversal device on aircraft;4.

Contact Now

Class: E316HTX-XAWS: A5.22Conforms to Certification: AWS A5.22 ASME SFA A5.22Weld Process: Gas Metal ArcAWS Chemical Composition RequirementsC = 0.04 – 0.08S = 0.03 maxMn = 0.5 – 2.5Cr = 17.0 – 20.0Si = 1.0 maxNi = 11.0 – 14.0P = 0.04 maxMo = 2.0 – 3.0Cu = 0.75 maxApplicationElectrodes of this classification usually are used for welding similar alloys.

Contact Now

304L stainless steel is a variant of the lower carbon 304 stainless steel, used for welding occasions.

Contact Now

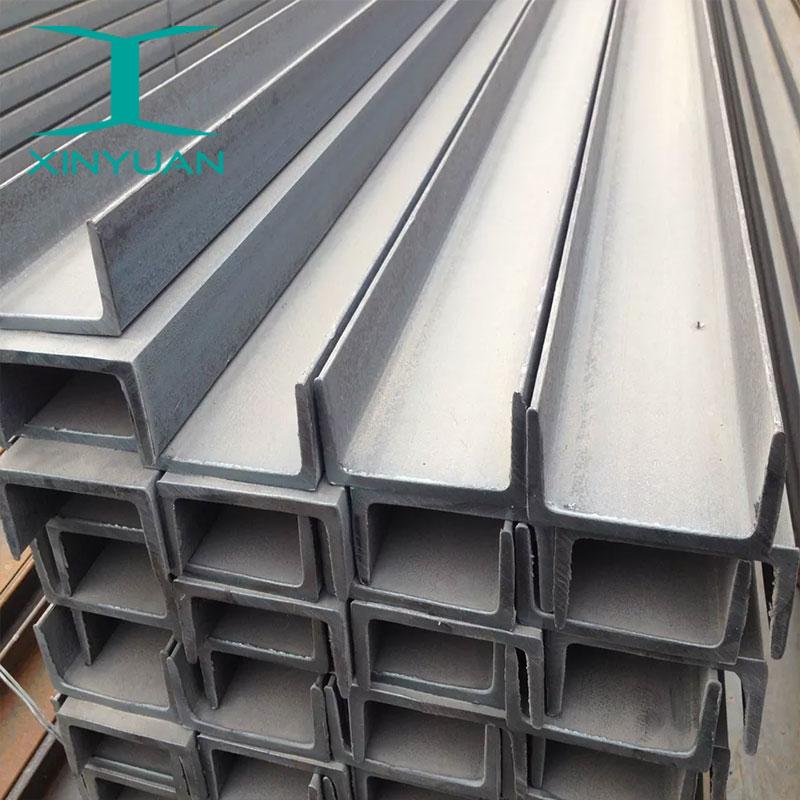

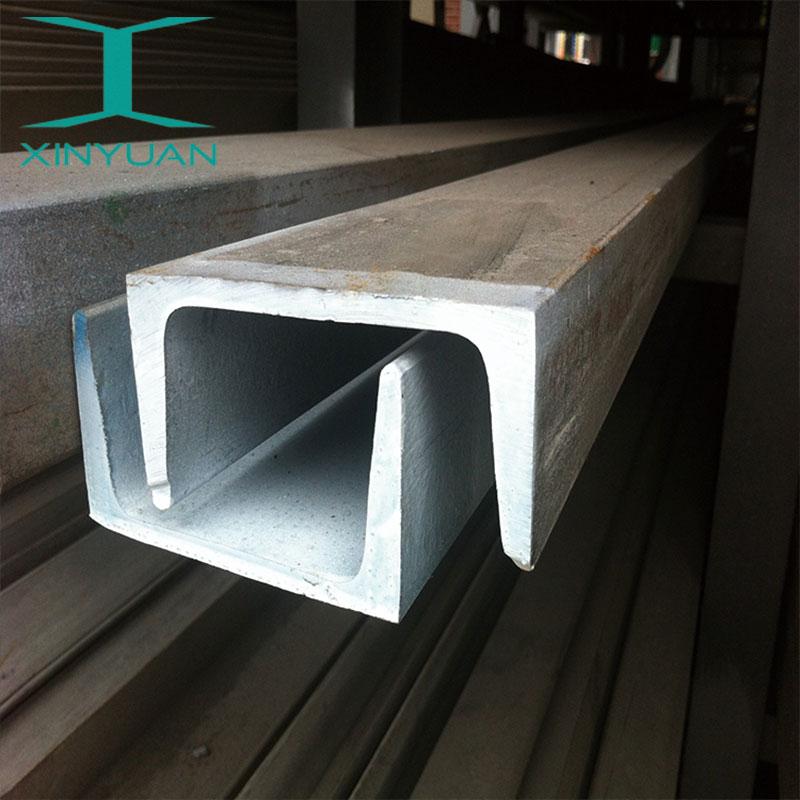

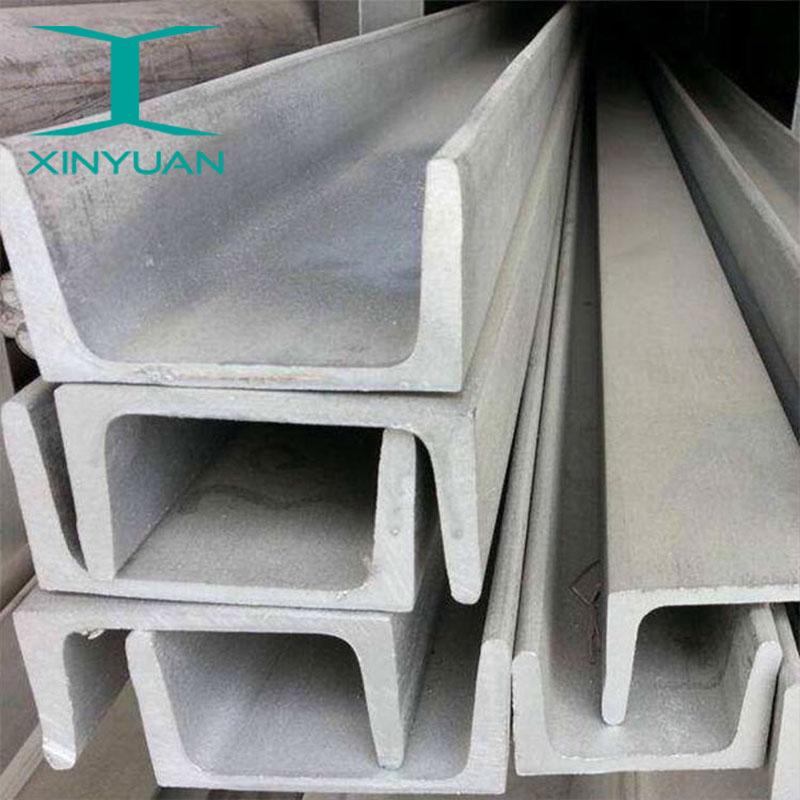

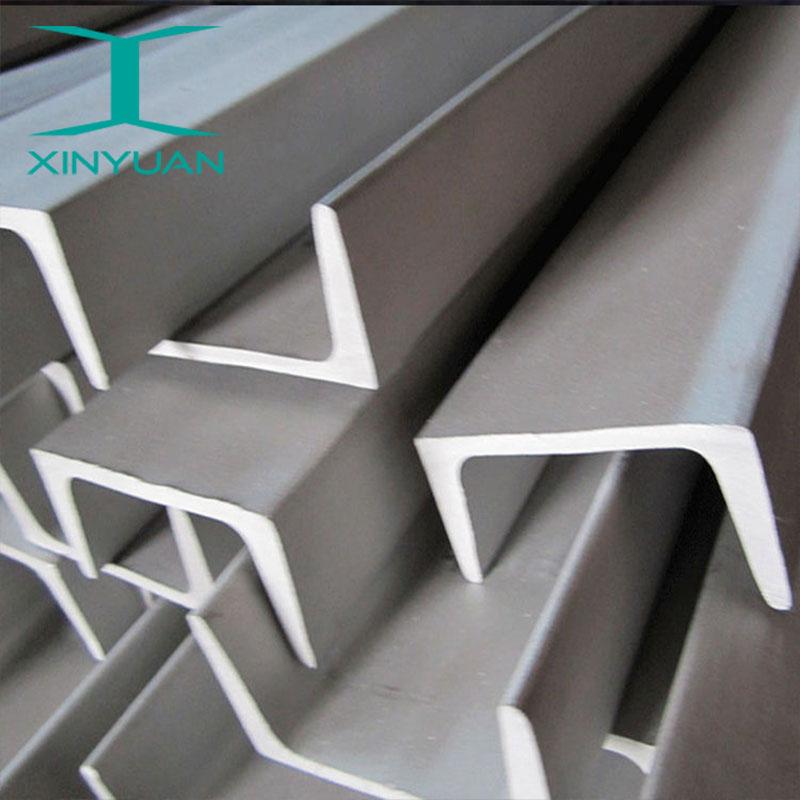

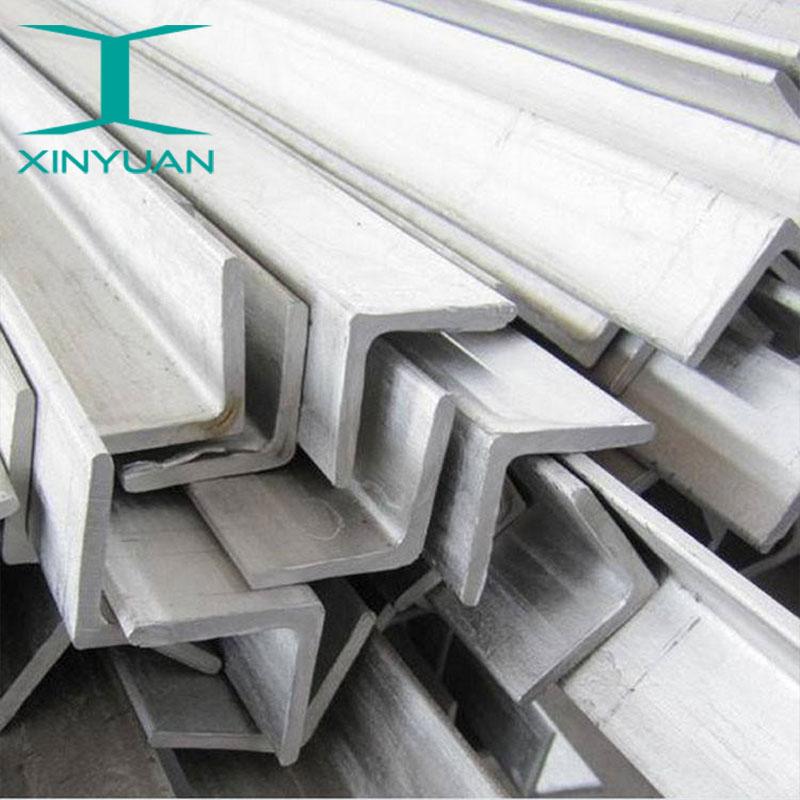

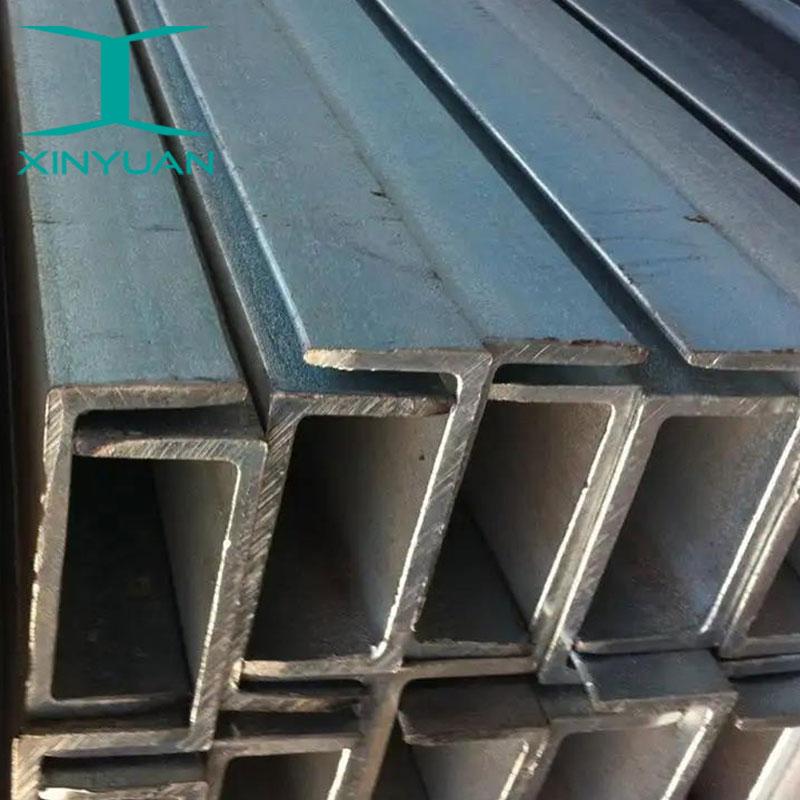

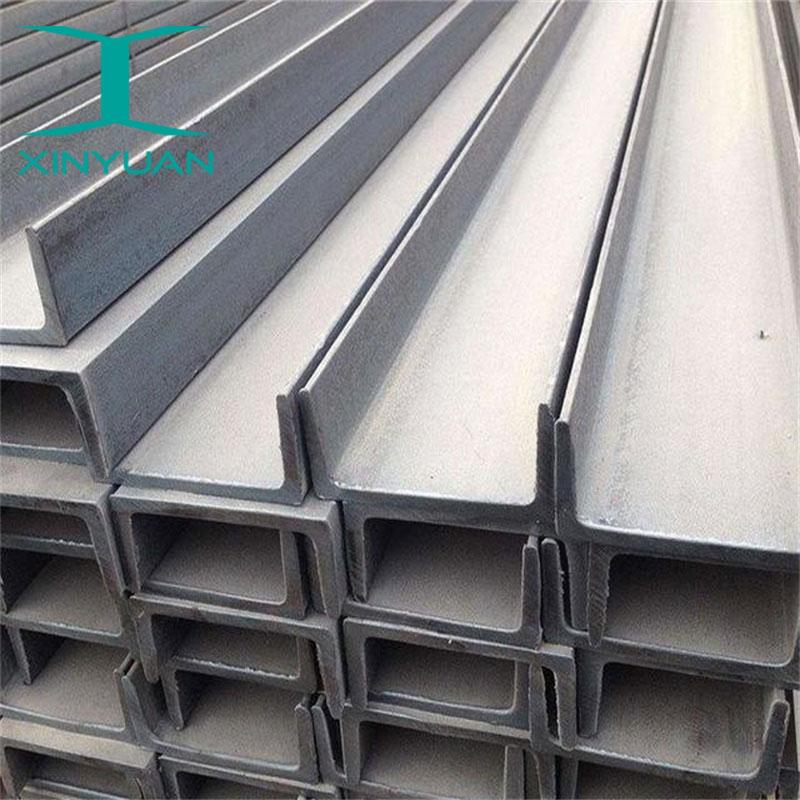

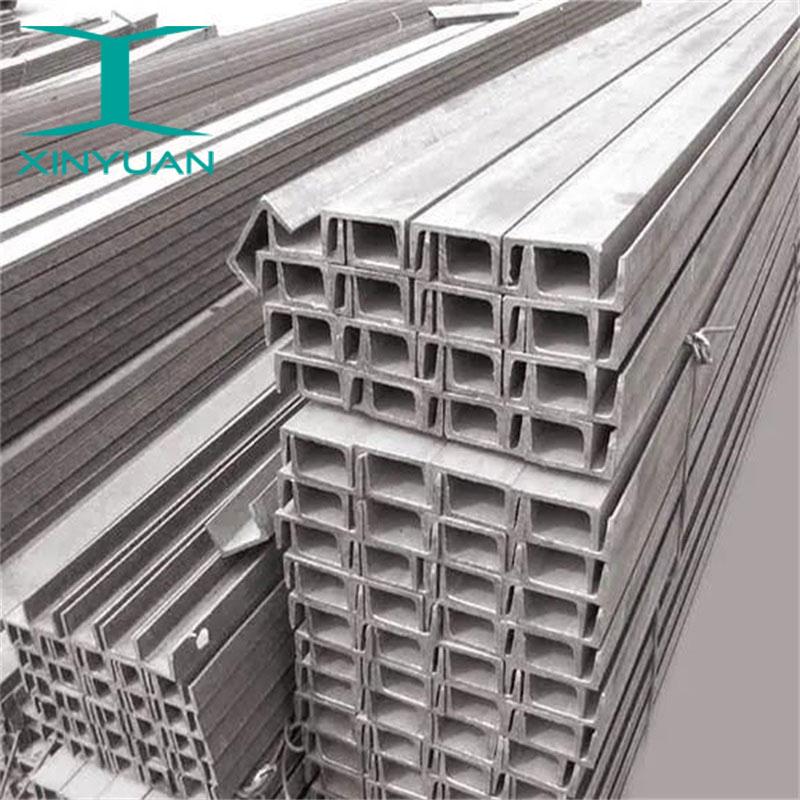

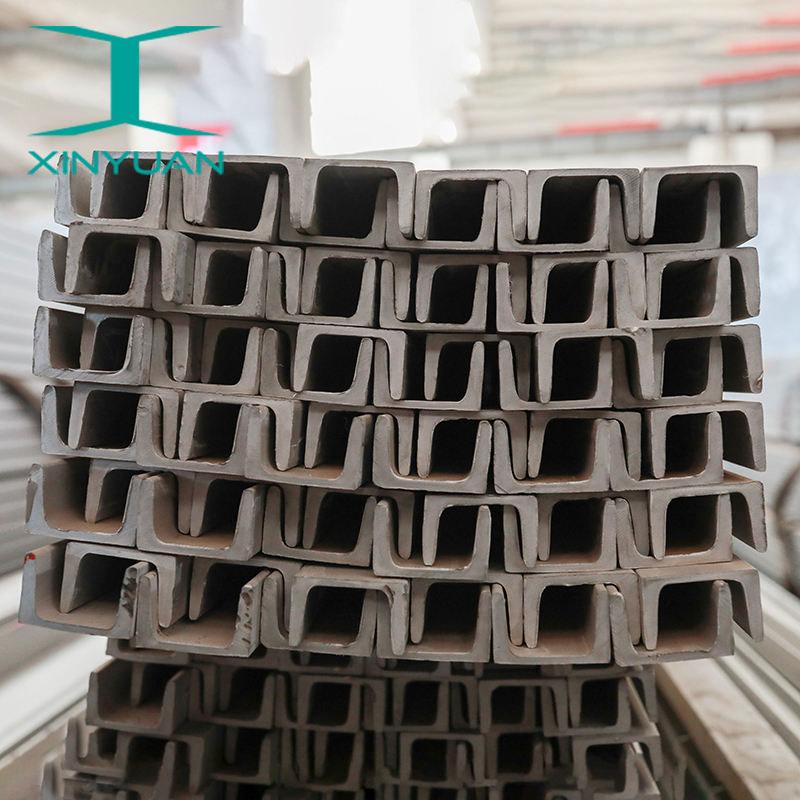

Channel steel is divided into ordinary channel steel and light channel steel.The specification of hot-rolled common channel steel is 5-40#.The specification of hot rolled flexible channel steel supplied by both parties is 6.5-30.Channel steel is mainly used for building structures, vehicle manufacturing, other industrial structures, and fixed tray cabinets, etc.

Contact Now

Channel steel is a long strip of steel with a groove section. A section shaped like a groove. Channel steel is a carbon structural steel used in construction and machinery. It is a section steel with a complex cross-section and its section shape is a groove shape. Channel steel is mainly used in building structure, curtain wall engineering, mechanical equipment and vehicle manufacturing.

Contact Now

316 Stainless steel channel steel is mainly used in building structure, vehicle manufacturing and other industrial structure, channel steel is often used with I-steel. 1, hot rolled stainless steel ordinary channel steel (GB707-88) main uses: ordinary channel steel is mainly used in building structure, vehicle manufacturing and other industrial structure, often used with I-beam. 2.

Contact Now

440 stainless steel channel steel is mainly used for building structure, vehicle manufacturing and other industrial structure, often used with beams.Product Parameter:Product NameStainless Steel ChannelSize50*37*4.5 - 400*104*14.5SurfaceBA, 2B, 2D, 4K, 6K, 8K, NO.4, HL, SB, EmbossedThinckness4.5mm-14.5mmWidthness50mm~2000mm or customizedLength1000mm~6000mm or customizedPackingIndustry standard packaging or according to client's requirementTechniqueCold Drawn/Cold pilfered/Cold rolled/Hot rolled/forge-Can be processed again repeatedlyStantardAISI, ASTM, BS, DIN, GB, JISMaterialsWe can offer

Contact Now

304 Stainless steel channel is an excellent candidate for most processing techniques as well as both indoor and outdoor applications. This product has a semi-smooth, dull grey finish and tapered legs. 304 stainless steel is a high strength material with excellent corrosion resistance making it idea for walkways, ramps, and other architectural uses.

Contact Now

The 430 bright annealed custom C-Channel (BA) finish is cold rolled stainless steel that is annealed in a controlled atmosphere to retain a highly reflective finish. Although it is not completely identical to the #8 mirror finish, it appears to be very similar.

Contact Now

316Ti Stainless Steel C-Channel is referred to as the stabilized grade of the 316 types, and also recommended for higher temperature situations.

Contact Now

202 stainless steel is one of the 200 series stainless steels, the national standard model is 1Cr18Mn8Ni5N. The 200 series stainless steel belongs to low nickel and high manganese stainless steel with a nickel content of about 8% and a manganese content of about 8%.

Contact Now

301 stainless steel strip is a kind of metastable austenitic stainless steel, which has a completely austenitic structure under the condition of full solution. Among the stainless steels, 301 is the steel that is most easily strengthened by cold deformation. Cold deformation can increase the strength and hardness of the steel and retain sufficient plasticity and toughness. In addition, this steel has good rust resistance under atmospheric conditions.

Contact Now

304L stainless steel is also known as environmentally friendly low-carbon stainless steel. As a low-carbon 304 stainless steel, its corrosion resistance is similar to that of 304 in general use scenarios, but 304L stainless steel can also maintain good resistance after welding or stress relief. It has excellent corrosion resistance and can maintain excellent corrosion resistance without heat treatment. The operating temperature range can reach -196℃-800℃.

Contact Now

Unlike mild steel the chemistry of stainless steels means the processes and methods for protecting and finishing 316 Grade Stainless Steel are vastly different to mild steels. Most surface finishes for stainless steel will be mechanically (Polishing) or chemically (Passivating) applied. The correct surface finish will have substantial impacts on the performance and appearance of your stainless steel. Product Parameter:Product NameStainless Steel ChannelSize50*37*4.5 - 400*104*14.5SurfaceBA, 2B, 2D, 4K, 6K, 8K, NO.4, HL, SB, EmbossedThinckness4.5mm-14.5mmWidthness

Contact Now

Our Stainless Steel 309 Angles/ Channels also has various advantages such as it has the heating elements, carbon saggers, waste incinerators, heat exchangers and much more.Product Parameter:Product NameStainless Steel ChannelSize50*37*4.5 - 400*104*14.5SurfaceBA, 2B, 2D, 4K, 6K, 8K, NO.4, HL, SB, EmbossedThinckness4.5mm-14.5mmWidthness50mm~2000mm or customizedLength1000mm~6000mm or customizedPackingIndustry standard packaging or according to client's requirementTechniqueCold Drawn/Cold pilfered/Cold rolled/Hot rolled/forge-Can be processed again repeatedlyStantardAISI, ASTM, BS, DIN, GB, J

Contact Now

Able to deliver goods quickly Tightly packed Stainless Steel 304/316/304L/316L anti-rust oil of plate flangeItemDescriptionBasic InformationMaterial GradeWP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etcSize1/2" to 48" Sch 5S to XXSStandardASTM A403 etc .Process MethodForged / CastingIndustry & AdvantageApplicationa) Connect pipesAdvantagea) High technology ; good surface ; high quality etcTerms & ConditionsPrice ItemFOB , CFR , CIF or as negotiationPaymentT / T

Contact Now