2507 Stainless Steel Square Bar2507 stainless steel is used in the oil and gas industry; offshore Shipotian oil platforms (heat exchanger tubes, water treatment and water supply systems, fire protection systems, water spray systems, water stabilization systems; petrochemical equipment; desalination (desalination) equipment (and equipment in high-pressure pipes, seawater pipes); mechanical and structural components that require both high strength and high corrosion resistance; combustion (exhaust) gas purification equipment.

Contact Now

317L hexagonal bar can be cold-drawn. For some demanding applications, 4% or more molybdenum in the welding coating of type 317 alloy hex bar is desirable.

Contact Now

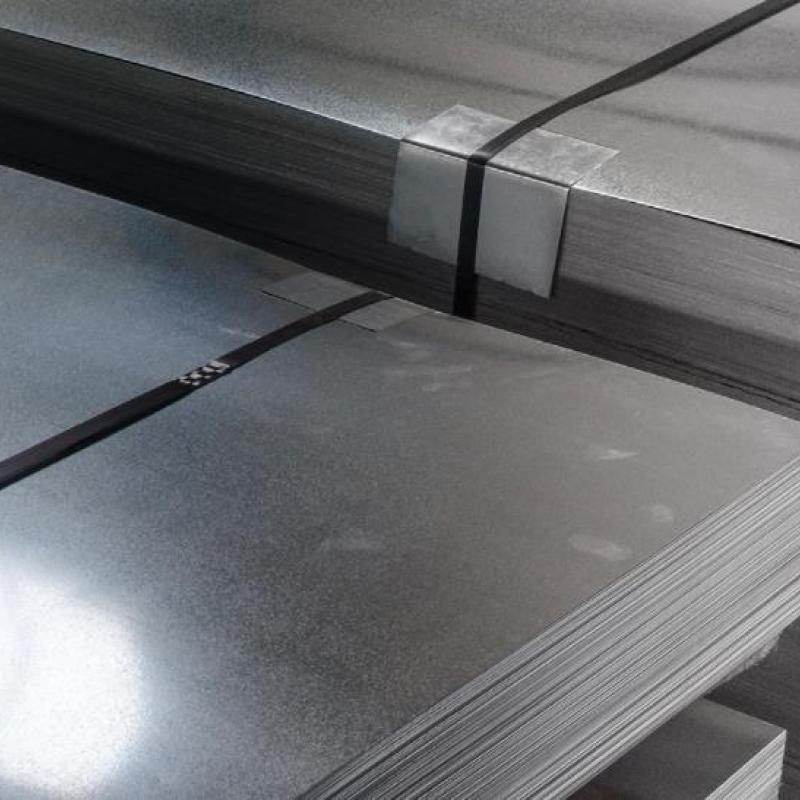

In our extensive line of products, we offer stainless steel sheet and stainless steel plates.WHAT IS STAINLESS STEEL SHEET?Stainless steel sheet is typically sold in the annealed condition and is available in most grades. Our stainless steel sheets come in both a standard 2B finish and various polished finishes. Polished surfaces range from the standard #4 to a mirrored finish #8 and are usually covered with a removable vinyl coating. Our standard sheet sizes include 4’ x 8’, 4’ x 10’, and 5’ x 10’, but customized sizes are also available.

Contact Now

Well known for its high impact strength, UNS S32760 displays no ductile-brittle transition but only a slight reduction in impact energy as temperature decreases.

Contact Now

Popular for its corrosion resistance, stainless-steel rod is utilized in a extensive variety of applications along with the development of constructing foundations, bridges, and marine environments.we have black bright surface, and distinct materials including 201 304 304l 316 316l 2205 2507 430 420 410 so as to select.Product Parameter:ProductStainless Steel BarBase materialstainless steel 200 series,300 series,400 seriesThickness0.40-5.00mmDiameter6-273mmstandardASTM A554/DIN/EN10296-2/JIS G3446,A269,A249,A270,EN10204 3.1QualitySGCC,SGCH,SGCE,SPCG,DX51Dsurface finishMill,Brush/Satin/Hairline

Contact Now

Duplex Steel UNS S32205 Round Bars have a long service life and low maintenance cost and hence can be used in various industrial applications like oil and gas exploration and processing equipment, chemical and petrochemical processing equipment, high chloride and marine environments, power generation, specialty chemicals, gas processing, seawater equipment, pulp and paper digesters, etc.Product Parameter:Stainless Steel barMaterial200 series: 201,202,202Cu,204Cu,300 series: 301, 303/Cu, 304/L/H, 304Cu, 305, 309/S, 310/S, 316/L/H/Ti, 321/H, 347/H, 330,400 series: 409/L, 410, 416/F, 420/F, 430,

Contact Now

Application:Mechanical&manufacture,Steel structure,Shipbuilding,Bridging,Automobile chassis.Product Parameter:Product namestainless steel H-beam / I-beamStandardJIS, AiSi, ASTM, GB, DIN, ENSize100mm-900mmWall thickness1.5mm-28mmMaterial grade301 303 303Cu 304 304J1 304L 316 316L 309S 310S 316Ti 321 430 420 410 409L 904LApplicationHardware products, medical machinery, food machinery, ships, cars, doors and Windows, furniture, large machinery, etcProcessing ServiceBending, Welding, Decoiling, Punching, Cutting, MouldingKeywordStainless steel profile,stainless steel bar,huel bars,rod,steel ro

Contact Now

309S Stainless Steel Flux Cored Welding Wire309S Stainless Steel Flux Cored Welding Wire Compared with manual welding rod and argon arc welding wire, flux cored wire has obvious advantages, mainly changing the intermittent welding process into a continuous production mode, thus reducing the number of welding joints, improving the quality of welds, improving production efficiency and saving energy.309S Stainless Steel Flux Cored Welding Wire detailsProduct Parameter:CommodityStainless Steel Welded Wire/Stainless Steel RodSt

Contact Now

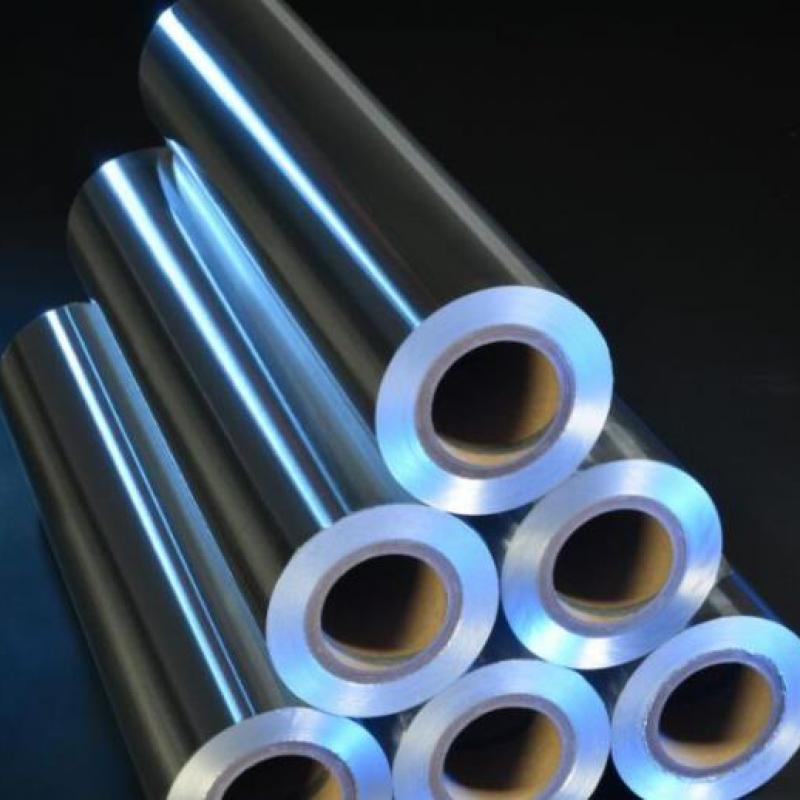

Through integrated production control, stainless steel foil that is excellent in etching properties and press formability, in addition to ultimately high thickness accuracy, strength, and spring characteristics. Stainless Steel FoilStainless steel foil is produced through the highly accurate rolling of stainless steel to be as thin as 100 mm, thus it has excellent flexibility, lightweight characteristics, and corrosion resistance.

Contact Now

Brilliant chrome steel coil refers to a type of stainless-steel coil that has a elegant or reflective surface finish. this finish is done through a process called electropolishing or by using the use of abrasives in the course of the manufacturing process.The bright surface end on chrome steel coils gives several blessings. it provides a clean and appealing appearance, making it a popular choice for ornamental applications, including trim, architectural capabilities, and jewelry.

Contact Now

ER410 H1Cr13 Y410 510 25 13Cr steel, the deposited metal is 13Cr, with high hardenability, excellent oxidation resistance and corrosion resistance at high temperature, suitable for welding of AISI410 or 420.ER410 flux-cored stainless steel wire Application: used for welding 410 or 420 series stainless steel, with high hardening, high temperature oxidation resistance, corrosion resistance, used in petroleum refining and chemical industry and surfacing repair, such as 12Cr13 (sus410)Products DescriptionWarranty3 yearsCustomized supportOEM, ODMPlace of OriginChinaBrand NameXINYUANModel NumberER41

Contact Now

Inconel 601 Seamless PipeThe performance characteristics of Inconel601 are better than 600. It is an alloy with high chromium content. It has excellent oxidation and corrosion resistance. Because the composition also contains aluminum, it has good oxidation resistance and curing performance.

Contact Now

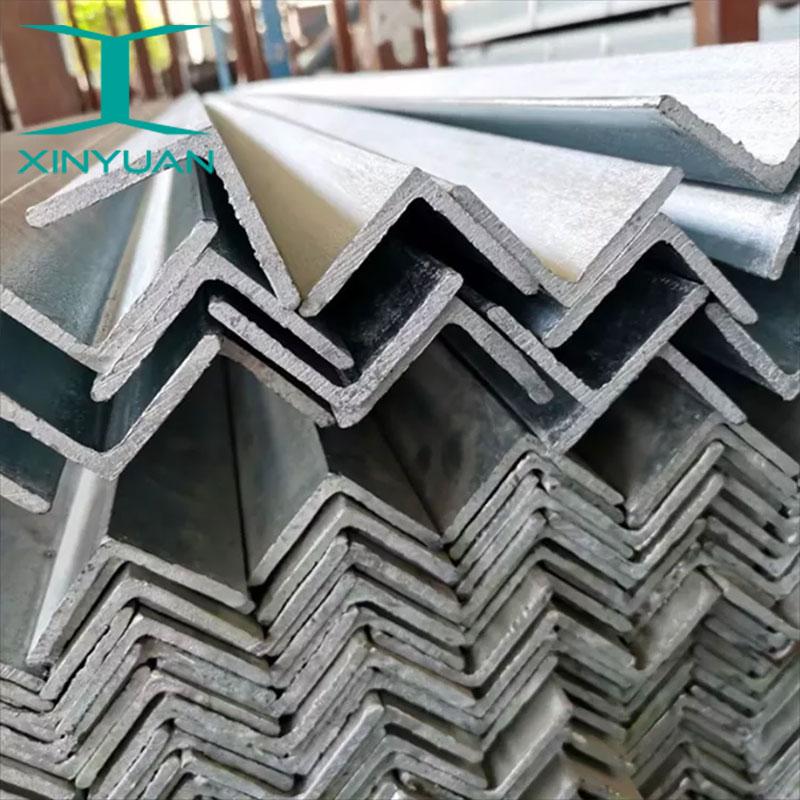

Stainless steel mind-set is a product which has legs to form a ninety diploma perspective.This product is designed for use in both structural packages and elegant fabrication.Stainless steel attitude’s type of programs are extensive and might consist of trailer manufacturing, protection cages, walkways and farming gadget.

Contact Now

Angle steel can make up different stress components according to the different needs of the structure, as the connection between components. Widely used in a variety of building structures and engineering structures, such as beams, Bridges, transmission towers, lifting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouses.Product Parameter:NameStainless Steel angle barStandardASTM A276, A484, A479, A580, A582, JIS G4303, JIS G4311,DIN 1654- 5, DIN17440,GB/T 1220 ectMaterialMainly 201, 202, 304, 304L, 304H, 316, 316L,316T

Contact Now

1 Stainless-steel perspective sheet blanketed with wood plate for safety in transportation.2. All stainless steel attitude twill be loaded in sturdy timber programs.3. Each cartons loaded with well shoring and strengthening.4. Take field loading pictures and seal the container.5. Transportation pace is brief.

Contact Now

1 Stainless steel angle sheet covered with wooden plate for protection in transportation.2. All stainless steel angle twill be loaded in strong wooden packages.3. Every cartons loaded with good shoring and strengthening.4. Take container loading pictures and seal the container.5. Transportation speed is quick.

Contact Now

Stainless Steel Angles Slotted Angle Bar Perforated is a product which has legs to shape a ninety diploma perspective.This product is designed for use in both structural programs and fashionable fabrication.Stainless steel mind-set’s type of packages are vast and might consist of trailer production, protection cages, walkways and farming machine.

Contact Now

316 stainless steel chemical composition:C≤0.08, Si≤1.00, Mn≤2.00, P≤0.035, S≤0.03, Ni:10.0-14.0, Cr:16.0-18.5, Mo:2.0-3.0.

Contact Now

316/316L Stainless Steel Angle BarStainless Steel Angle 316/316L is an angle shaped 316/316L Stainless Steel Alloy. 316 Stainless Steel Alloy is a standard molybdenum-bearing grade, the second most commonly sought after grade next to grade 304 amongst the austenitic stainless steels. The molybdenum gives 316 better overall corrosion resistant properties than Grade 304, particularly higher resistance in chloride environments.

Contact Now

it's miles regularly utilized in diverse creation and engineering metal structures, including beams, bridges, towers, lifting machinery, ships, business furnaces, response towers, container shelves and warehouse cabinets.Product Parameter:NameStainless Steel angle barStandardASTM A276, A484, A479, A580, A582, JIS G4303, JIS G4311,DIN 1654- 5, DIN17440,GB/T 1220 ectMaterialMainly 201, 202, 304, 304L, 304H, 316, 316L,316Ti,2205, 330, 630, 660, 409L, 321, 310S, 410, 416, 410S, 430, 347H, 2Cr13, 3Cr13 et200series:201,202,202cu,204300series:301,302,303,304,304L,309,309s,310,310S,316,316L,316Ti,

Contact Now

The 316 material can resist the chloride ion stress corrosion because of the 4% molybdenum in the content. There are different Stainless Steel 304 Unequal Angle Sizes depending on the application requirements. The angles are used to connect components together with a grip. There are angles with bolt holes for bolts or screws as well. The 316 Stainless Steel Unequal Angle is used in more corrosive applications than the 304 angles could be used. The Stainless Steel Unequal Angle is as common as the equal angle.

Contact Now

316 Stainless Steel Hex Bar316 Stainless Steel Hex Bar exhibits high strength and excellent corrosion resistance including in marine environments. 316 is slightly stronger than 304 stainless and is rated as a marine metal. 316 maintains its properties in cryogenic or high temperatures.

Contact Now

Place of Origin:Tianjin, ChinaStandard:ASTM, AiSi, DIN, EN, GB, JISApplication:Industry/Chemical Equipment/KitchenSize:200series,300series,400seriesthickness:0.5mm-10mmTechnical Test:UT Test, Bending Test, Charpy TestTolerance:±1%Processing Service:Welding, DecoilingGrade:201/202/304/304L/316/316L321/310s/410Delivery Time:8-14DaysTechnique:Hot Rolled Angle BarPrice Term:CIF CFR FOB EX-WORKType:Equal and UnequalFinish:Brush PolishSize:Customized SizePayment Term:30%T/T Advance + 70% BalanceSample:Free-sampleSize of the stainless steel angle25*25*375*75*6125*125*1232*20*475*50*8110*70*825*25*475

Contact Now

Ha alloy, duplex stainless-steel 316 304 and different stainless steel substances, the sort of its commercial enterprise is steel plate, steel pipe, round steel, and so on., may be custom designed in keeping with patron name for processing.316 stainless steel, 18CR-12Ni-2.5Mo due to the addition of Mo, so its corrosion resistance, atmospheric corrosion resistance and high temperature strength is particularly good, can be used under harsh conditions; Excellent work hardening (no magnetic).

Contact Now