Stainless Steel Sanitary Clamped 45 90 180 Degree Bend Elbow 304 316lProduct Description of Stainless Steel ElbowPIPE FITTINGSProduction Name45 / 90 / 180 , Long / Short Radius Elbows, Equal / Reducing Crosses, Concentric / Eccentric Reducers, Caps, Stub EndsSize RangeFrom ½" up to 72" From 1/2 to 30 (Seamless Pipe Fittings),Form16to 72(Seam Pipe Fittings)ScheduleSCH STD, XS, XXS, S

Contact Now

SL Food Grade 19mm/25/32/38/45/51mm OD Sanitary Butt Weld 90 Degree Elbow Bend Pipe 304 stainless steel FittingProduct Description of Stainless Steel ElbowPIPE FITTINGSProduction Name45 / 90 / 180 , Long / Short Radius Elbows, Equal / Reducing Crosses, Concentric / Eccentric Reducers, Caps, Stub EndsSize RangeFrom ½" up to 72" From 1/2 to 30 (Seamless Pipe Fittings),Form16to 72(Seam Pipe Fittings)Sched

Contact Now

sus304 sus316L sanitary stainless steel pipe fitting 90 180 degree welding elbowProduct Description of Stainless Steel ElbowPIPE FITTINGSProduction Name45 / 90 / 180 , Long / Short Radius Elbows, Equal / Reducing Crosses, Concentric / Eccentric Reducers, Caps, Stub EndsSize RangeFrom ½" up to 72" From 1/2 to 30 (Seamless Pipe Fittings),Form16to 72(Seam Pipe Fittings)ScheduleSCH STD, XS,

Contact Now

StandardASTM A479,ASTM A276,ASTM A484, ASTM A582, ASME SA276, ASME SA484, GB/T1220, GB4226, etc.Material301, 304, 304L, 309S, 321, 316, 316L, 317, 317L, 310S, 201,202321, 329, 347, 347H 201, 202, 410, 420, 430, S20100, S20200, S30100, S30400, S30403, S30908, S31008, S31600, S31635, etc. SpecificationsRound barDiameter:0.1~500mmAngle barSize: 0.5mm*4mm*4mm~20mm*400mm*400mmFlat barThickness0.3~200mmWidth1~2500mmSquar

Contact Now

1) Test methods.① Tensile test method. Commonly used standard test methods are GB/T228-87, JISZ2201, JISZ2241, ASTMA370, ГОСТ1497, BS18, DIN50145, etc..② Bending test method. Commonly used standard test methods are GB/T232-88, JISZ2204, JISZ2248, ASTME290, ГОСТ14019, DIN50111, etc.(2) performance indicators: the test items to assess the performance of angle steel are mainly tensile test and bending test.

Contact Now

Well known for its high impact strength, UNS S32760 displays no ductile-brittle transition but only a slight reduction in impact energy as temperature decreases.

Contact Now

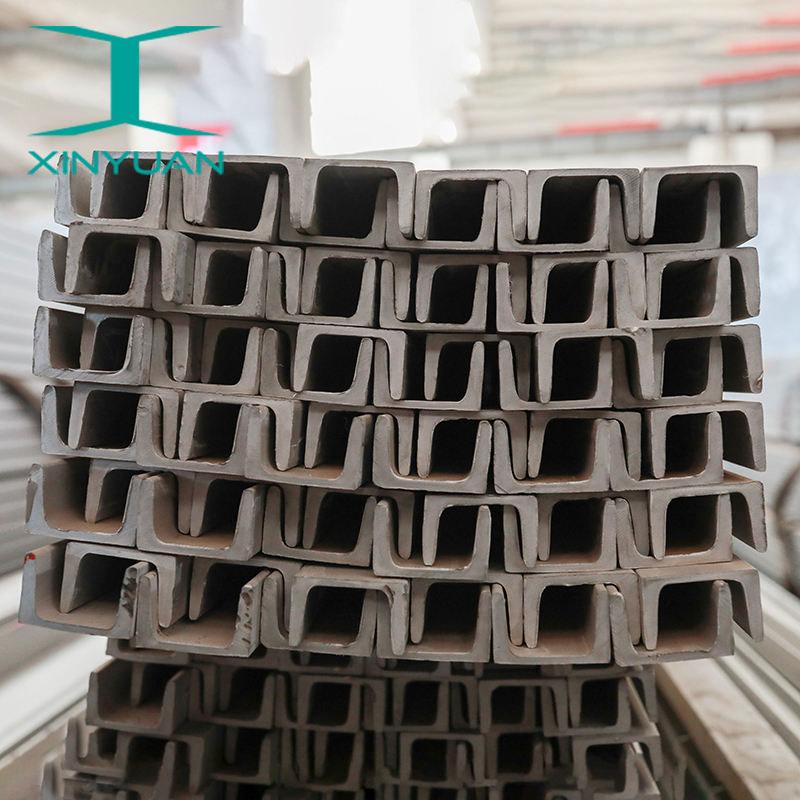

Our Stainless Steel 309 Angles/ Channels also has various advantages such as it has the heating elements, carbon saggers, waste incinerators, heat exchangers and much more.Product Parameter:Product NameStainless Steel ChannelSize50*37*4.5 - 400*104*14.5SurfaceBA, 2B, 2D, 4K, 6K, 8K, NO.4, HL, SB, EmbossedThinckness4.5mm-14.5mmWidthness50mm~2000mm or customizedLength1000mm~6000mm or customizedPackingIndustry standard packaging or according to client's requirementTechniqueCold Drawn/Cold pilfered/Cold rolled/Hot rolled/forge-Can be processed again repeatedlyStantardAISI, ASTM, BS, DIN, GB, J

Contact Now

The density of 304 stainless steel 7.93 g/cm3 austenitic stainless steel generally used this value 304 chromium content (%) 18--20.304 is equivalent to our 0Cr19Ni9 (0Cr18Ni9) stainless steel 304 stainless steel is a universal stainless steel material, Rust resistance is better than 200 series stainless steel material. High temperature resistance is also relatively good, can be as high as 1000-1200 degrees. 304 stainless steel has excellent corrosion resistance and corrosion resistance between grains.

Contact Now

High temperature resistant to 800°C and processability. Common labeling methods on the market include 0Cr18Ni9 and SUS304.

Contact Now

310 Stainless Steel Angles are manufactured using high-grade steel, which contains chromium, nickel, and additional molybdenum, niobium, titanium, and nitrogen. These additional elements offer excellent tensile strength, high surface finish, outstanding corrosion & oxidation resistance, and good mechanical properties.

Contact Now

301 stainless steel bar is a metastable austenitic stainless steel with complete austenitic structure under the condition of full solution.

Contact Now

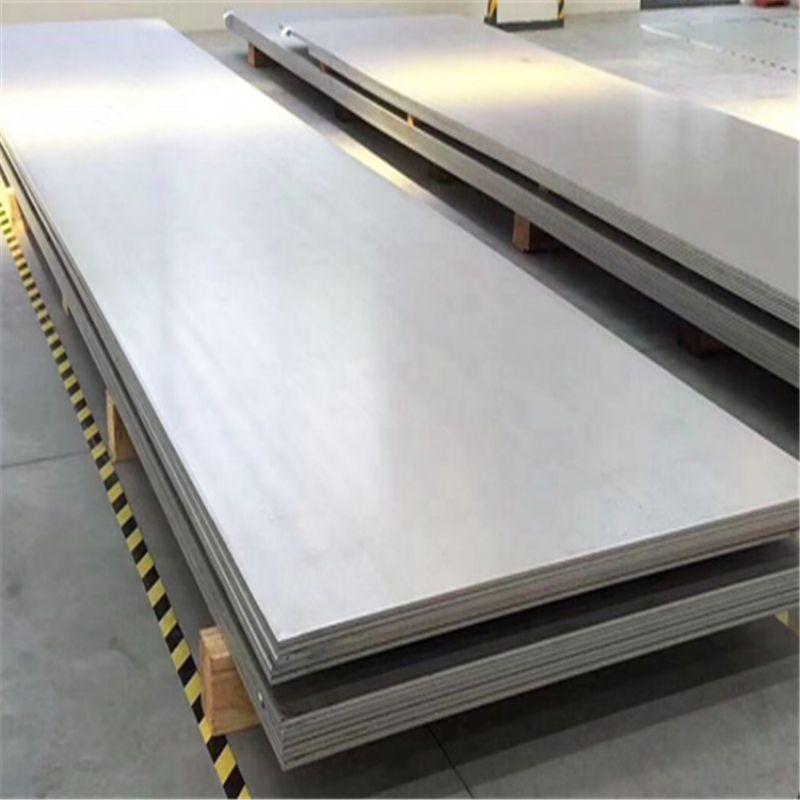

ProductStainless Steel Sheet/Plate/CoilSurface FinishBA, 2B, 2D, 4K, 6K, 8K, NO.4, HL, EmbossedTechniqueHot Rolled / Cold RolledStandardGB JIS ASTM ASME ENSteel Grade200 series: 201 202300 series: 301 304 304L 309 310 310s 316 316L 321400 series: 409 410 410S 420 430ColorStandard RAL color:red,bule,white,grey,brick,etc.Stock Dimension0.5mm-4mm x 1220mm/1500mm x 2440mm/2500mm;5mm-25mm x 1220mm/1500mm x 2440mm/2500mm/6000mm;8mm-80mm x 1500/1800/2000mm/2500 x 6000mm;cut to size according to customers' demandsServiceOEM, customized processing service, customized fabrication by drawingsProcessi

Contact Now

ProductStainless Steel Sheet/Plate/CoilSurface FinishBA, 2B, 2D, 4K, 6K, 8K, NO.4, HL, EmbossedTechniqueHot Rolled / Cold RolledStandardGB JIS ASTM ASME ENSteel Grade200 series: 201 202300 series: 301 304 304L 309 310 310s 316 316L 321400 series: 409 410 410S 420 430ColorStandard RAL color:red,bule,white,grey,brick,etc.Stock Dimension0.5mm-4mm x 1220mm/1500mm x 2440mm/2500mm;5mm-25mm x 1220mm/1500mm x 2440mm/2500mm/6000mm;8mm-80mm x 1500/1800/2000mm/2500 x 6000mm;cut to size according to customers' demandsServiceOEM, customized processing service, customized fabrication by drawingsProcessi

Contact Now

Super Duplex 2507 PipeSuper Duplex 2507 Pipe is a exquisite duplex cloth made steel pipe. The high-quality duplex is an alloy of chromium, molybdenum and nickel. The fabric has very excessive corrosion resistance houses and is resistant to pitting corrosion, crevice corrosion and uniform corrosion as well. The Alloy 2507 Seamless Pipes are produced via a technique referred to as the cold drawing. Cold drawn pipes are seamless or have clean surfaces. They are proper to be used in aesthetic searching and unique applications.

Contact Now

2507 Stainless Steel Pipe is a super duplex grade for which elements chromium, nickel and molybdenum are the primary alloyants.

Contact Now

super duplex 2507 round bar is an alloy which has been designed for applications that demand exceptional tensile strength and superior resistance to corrosion as well.Product Parameter:Stainless Steel barMaterial200 series: 201,202,202Cu,204Cu,300 series: 301, 303/Cu, 304/L/H, 304Cu, 305, 309/S, 310/S, 316/L/H/Ti, 321/H, 347/H, 330,400 series: 409/L, 410, 416/F, 420/F, 430, 431, 440C, 441, 444, 446,600 series: 13-8ph, 15-5ph, 17-4ph, 17-7ph(630,631), 660A/B/C/D,Duplex: 2205(UNSS31803/S32205), 2507(UNSS32750), UNSS32760, 2304, LDX2101.

Contact Now

Advantagesa) Advanced era of cold draw deviceb) Advanced annealing gadgetc) Better mechanical propertyd) More particular dimensione) Perfect inspection approach and inspection system and so forthProduct NameSS 316L Pipe Tp304L 316L 904L 304 1.4301 316 310S 321 430 2205 2507 Bright Annealed Seamless Stainless Steel Pipe Tube For Instrumentation StandardGB,AISI,ASTM,DIN,EN,JISGradeStainless steel 304 / 304L / 310S / 316L / 316Ti / 316LN / 317L / 904L / 2205 / 2507 / 32760 / 253MA / 254SMo / XM-19 / S31803 /S32750 / S32205 / F50 / F60 / F55 / F60 / F61 / F65 etcMonel 400 / Monel K-500Inconel

Contact Now

Our production facility can customise the coloration, specification and period of the goods in keeping with your necessities, and the packaging field can customise the emblem and fashion consistent with your requirements.

Contact Now

317L Austenitic Stainless Steel Wire 317L Austenitic Stainless Steel Wire ’s Mechanical properties:317L mechanical properties: ys (MPA) ≥ 176, TS (MPA) ≥ 480, EL (%) ≥ 40, HV ≤ 200317L Austenitic Stainless Steel Wire 's chemical composition317L chemical composition: carbon (c) ≤ 0.030, manganese (MN) ≤ 2.00, nickel (Ni) 11.0 ~ 15.0, silicon (SI) ≤ 1.00, phosphorus (P) ≤ 0.045, sulfur (s) ≤ 0.030, chromium (CR) 18.0 ~ 20.0, molybdenum (MO) 3.0 ~ 4.0Product Parameter:Weight1000(kg/km)Diameter0.2-14mmLengthAs requirementsMaterial201,301,302,303,304,304L,316,316L,317L,321,308,308L,309,309

Contact Now

The high nickel content of Incoloy 825 gives the alloy an effective resistance to stress corrosion cracking. The corrosion resistance is excellent in a variety of media, such as sulfuric, phosphoric, nitric and organic acids, alkali metals such as sodium hydroxide, potassium hydroxide and hydrochloric acid solutions.

Contact Now

PAPER INDUSTRY, ARCHITUCTURE, CONSTRUCTION, KITCHEN EQUIPMENT, PHARMA, ENGINEERING INDUSTRIES AND MANY MOREProduct Parameter:NameStainless Steel angle barStandardASTM A276, A484, A479, A580, A582, JIS G4303, JIS G4311,DIN 1654- 5, DIN17440,GB/T 1220 ectMaterialMainly 201, 202, 304, 304L, 304H, 316, 316L,316Ti,2205, 330, 630, 660, 409L, 321, 310S, 410, 416, 410S, 430, 347H, 2Cr13, 3Cr13 et200series:201,202,202cu,204300series:301,302,303,304,304L,309,309s,310,310S,316,316L,316Ti, 317L,321,347400series:409,409L,410,420,430,431,439,440,441,444Others:2205,2507,2906,330,660,630,631,17-4ph,17-7ph, S3

Contact Now

301 stainless steel strip is a kind of metastable austenitic stainless steel, which has a completely austenitic structure under the condition of full solution. Among the stainless steels, 301 is the steel that is most easily strengthened by cold deformation. Cold deformation can increase the strength and hardness of the steel and retain sufficient plasticity and toughness. In addition, this steel has good rust resistance under atmospheric conditions.

Contact Now

301 Antioxidant Stainless Steel Welded H-beam High Quality Stock China FactoryStainless steel H-shaped steel, with a thickness of 4.0mm-8.0mm, is widely used in beams and columns of industrial and civil construction steel structures. Steel structure load-bearing support for industrial structures. Ship and machinery manufacturing frame structure.

Contact Now

301 Stainless Steel Coil301 stainless metal coil is a kind of hardenable austenitic stainless metal with excessive strength, reasonable corrosion resistance and correct formability.

Contact Now