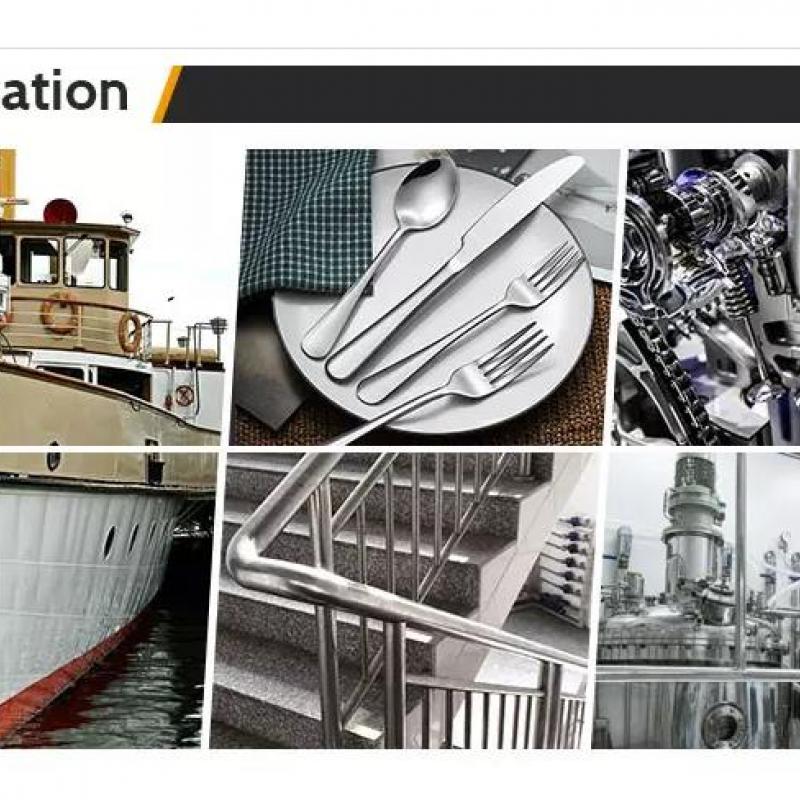

Incoloy 825 N08825 Hastelloy C-22 alloy coil Nickel Alloy Steel Sheet and Plate Hastelloy C276 alloy steel plateTypeNickel Alloy Sheet/PlateThickness0.8-36mmLength3000mm, 5800mm, 6000mm,etcWidth1000mm,1500mm,2000mm,etcStandardASTM,AISI,JIS,DIN,ENApplicationConstruction,Ship,Boiler,Machinery,etcCertificationISO,SGS,TUVTechniqueCold Rolled/Hot RolledEdgeMill Edge/ Silt EdgeGradeHastelloy: Hastelloy B/ -2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g;etcInconel 600/601/602CA/617/625/713/718/738/X-750;ETCIncoloy: Incoloy 800/800H/800HT/825/925/926;etcGH: GH2132,GH3030,GH3039,GH3128,GH4180,GH3044,etcM

Contact Now

I-beam, also known as steel beam (English name Universal Beam), is a long strip of steel with an I-shaped section. I-beams are divided into ordinary I-beams and light I-beams.

Contact Now

2507 dual-phase steel density: 8.03g/cm3, melting point: 1300-1390 ℃, magnetic: noneHeat treatment: heat preservation between 1000-1052℃ for 1-2 hours, rapid air cooling or water cooling.Mechanical properties: tensile strength: σb≥795Mpa, yield strength σb≥550Mpa: elongation: δ≥15%, hardness ≤310 (HB)Product Parameter:ItemStandardMaterialStainless SteelASTM201, 202, 301, 304, 304L, 304N, XM21, 304LN, 305, 309S, 310S, 316, 316Ti, 316L, 316N, 316LN, 317, 317L, 321, 347, 329,405, 409, 430, 434, 444, 403, 410, 420, 440A, etc.EN1.4372, 1.4373, 1.4319, 1.4301, 1.4306, 1.4315, 1.4303, 1.4833, 1.4845,

Contact Now

2205 2507 904L 254SMO POLISHED STAINLESS STEEL SEAMLESS/WELDED PIPE MANUFACTURERItemStainless Steel Tube/PipeSteel grade200series,300 series,400series,duplexStandardASTM A213,A312,ASTM A269,ASTM A778,ASTM A789,DIN 17456,DIN17457,DIN 17459,JIS G3459,JIS G3463,GOST9941,EN10216,BS3605,GB13296Material304,304L,309S,310S,316,316Ti,317,317L,321,347,347H,304N,316L, 316N,201,202SurfacePolishing,annealing,pickling,brightTypehot rolled and cold rolledstainless steel round pipe/tubeSizeWall thickness1mm-150mm(SCH10-XXS)Outer diameter6mm-2500mm (3/8"-100")stainless steel square pipe/tubeSizeWall

Contact Now

Inconel 601 Seamless PipeThe performance characteristics of Inconel601 are better than 600. It is an alloy with high chromium content. It has excellent oxidation and corrosion resistance. Because the composition also contains aluminum, it has good oxidation resistance and curing performance.

Contact Now

An l -beam is shaped like an I. The I beam consists of two horizontal planes, known as flanges, connected by one vertical component, or the web. I-beam has tapered edges and it gets its name from the fact that it looks like a capital I when you see it from its cross section.

Contact Now

The most common beam in our inventory, the I beam’s center web can only be rolled as much as a mill’s equipment can handle (5/8″).

Contact Now

The 304l stainless-steel i-beam is a chromium-nickel grade of metallic. it includes 8 percentage nickel and 18 percent chromium. it's miles a with ease machinable metallic that has remarkable formability and weldability. it has desirable corrosion-resistance and is even able to face up to intergranular corrosion, which could arise after welding or stress relieving. as it has a low content material of carbon, it could be accurately utilized in maximum welded construction operations that use temperatures no better than 800 tiers f.

Contact Now

I-beams are specially divided into ordinary i-beams, mild-obligation i-beams and large-flange i-beams. in line with the height ratio of flange and internet, it's miles divided into big, medium and narrow wide flange i-beams. the number one two are produced in size 10-60, this is, the corresponding peak is 10 cm-60 cm. light-weight i-beams have slender flanges, skinny webs and mild weight for the identical height. large flange i-beam, moreover called h-beam, is characterised via parallel legs and no slope at the interior of the legs.

Contact Now

Alloy 420 can be hardened by cold working and by heat treating.

Contact Now

Products Description1, Health type, fully meet the requirements of food grade standards 2, High temperature resistance, the maximum temperature of 1250 degrees. 3,Not afraid of wet, not afraid of water, can be soaked in water, completely deformed, do not rust. Product Namel stainless steel plateThickness0.1~150mmWidth600mm,1000mm,1219mm,1500mm,1800mm,2000mm,2500mm, 3000mm, 3500mm,etcLength2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etcStandardASTM GB/T JIS4 ASME BS DIN ENMaterial200 series: 201/202300 series: 301/304/304L/305/309S/310S/316/316L/316LN/316Ti/317/317L/347/347H400 serie

Contact Now

OEM ODM customized hot sale precision stainless steel threaded flangeItemDescriptionBasic InformationMaterial GradeWP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etcSize1/2" to 48" Sch 5S to XXSStandardASTM A403 etc .Process MethodForged / CastingIndustry & AdvantageApplicationa) Connect pipesAdvantagea) High technology ; good surface ; high quality etcTerms & ConditionsPrice ItemFOB , CFR , CIF or as negotiationPaymentT / T , LC or as negotiationDelivery Ti

Contact Now

a182 f304l f316l stainless steel pipe fitting loose flangeItemDescriptionBasic InformationMaterial GradeWP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etcSize1/2" to 48" Sch 5S to XXSStandardASTM A403 etc .Process MethodForged / CastingIndustry & AdvantageApplicationa) Connect pipesAdvantagea) High technology ; good surface ; high quality etcTerms & ConditionsPrice ItemFOB , CFR , CIF or as negotiationPaymentT / T , LC or as negotiationDelivery Time 30 workin

Contact Now

Stainless Steel FlangeFeatures of stainless steel products1) High strength;2) Excellent machinability3) Hardening occurs after heat treatment;4) Magnetic;5) Not suitable for harsh corrosive environment.Scope of applicationGeneral blades, mechanical parts, bolts, nuts, Class 1 tableware (spoons, forks, knives, etc.).ItemDescriptionBasic InformationMaterial GradeWP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etcSize1/2" to 48" Sch 5S to XXSStandardASTM A403 etc .Proce

Contact Now

slip on flange ASME B16.5 ss304L ss316L flanges plate flangeItemDescriptionBasic InformationMaterial GradeWP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etcSize1/2" to 48" Sch 5S to XXSStandardASTM A403 etc .Process MethodForged / CastingIndustry & AdvantageApplicationa) Connect pipesAdvantagea) High technology ; good surface ; high quality etcTerms & ConditionsPrice ItemFOB , CFR , CIF or as negotiationPaymentT / T , LC or as negotiationDelivery Time 30 work

Contact Now

Pipe Fitting Direct: Spectacle Blind Flange 3-1/2'' 600LB Stainless Steel 304L 321 316l ASTM A105 ASME B16.9 Eight 8 Word FlangesItemDescriptionBasic InformationMaterial GradeWP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etcSize1/2" to 48" Sch 5S to XXSStandardASTM A403 etc .Process MethodForged / CastingIndustry & AdvantageApplicationa) Connect pipesAdvantagea) High technology ; good surface ; high quality etcTerms & ConditionsPrice Item

Contact Now

ASTM A182 F11 F22 F5 F304 F316L F53 Stainless Steel Duplex Stainless Steel Slip on Flange So RF Flange Weld Neck Flange Blind FlangeItemDescriptionBasic InformationMaterial GradeWP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etcSize1/2" to 48" Sch 5S to XXSStandardASTM A403 etc .Process MethodForged / CastingIndustry & AdvantageApplicationa) Connect pipesAdvantagea) High technology ; good surface ; high quality etcTerms & ConditionsPrice ItemFOB , CFR , CIF or as

Contact Now

Application is very wide, below 980 ℃ has sufficient strength and corrosion resistance and oxidation resistance.1.Manufacture of springs and bolts working under high temperature; rotor blades, impellers and other structural parts of gas turbines;2. Thrust chamber on rocket engines;3. Thrust reversal device on aircraft;4.

Contact Now

With well equiped processing platforms including shearing,cutting,surface finishing,forming,welding and maching,Xinyuan Steel Co.,Ltd supply high quality stainless steel coils Specifications:Standard: ASTM A240, JIS G4304, EN100882. Grade: 200series&300series&400series3. Thickness: 0.03mm - 6.0mm4. Width: 8mm-600mm5. Length: as customers' request6.

Contact Now

430 stainless steel has oxidation resistance to corrosion, but has a tendency to intergranular corrosion.430 stainless steel wire is widely used in axis.Because it is safe and non-toxic, it is widely used in food tableware.Product Parameter:StandardASTM A479,ASTM A276,ASTM A484, ASTM A582,ASME SA276, ASME SA484, GB/T1220, GB4226, etc.Material301, 304, 304L, 309S, 321, 316, 316L, 317, 317L, 310S, 201,202321, 329, 347, 347H 201, 202, 410, 420, 430, S20100, S20200, S30100, S30400, S30403, S30908, S31008, S31600, S31635, etc.SpecificationsRound barDiameter:0.1~500mmAngle barSize: 0.5mm*4mm*4mm~20m

Contact Now

430 stainless steel is used for architectural decoration, fuel burner parts, household appliances, and home appliance parts. 430 is a ferritic stainless steel, and 430 16Cr is a representative steel grade of ferritic steel, with good thermal expansion rate, excellent formability and oxidation resistance.

Contact Now

The 304L is a variant of the lower carbon 304 stainless steel for use where welding is required.

Contact Now

Products DescriptionStainless steel is notable for its corrosion resistance, and it is widely used for food handling and cutlery among many other applications.CommodityHot and cold rolled stainless steel coil/sheet/pipe/stripGrade201,202,301,304,304j1,304l,321,309s,310s,2205,409l,410,410s,420,420j1,420j2,430,439,409l,443,444,etcStandardISO,JIS,ASTM,AS EN,GBsurfaceNO.1 /NO.2D /NO.2B /BA /NO.3 /NO.4 /NO.240 /NO.320 /NO.400 /HL /NO.7/ NO.8,etcThickness0.2-100mm(common:0.2-0.5mm)(Precision Stainless Steel Strip:0.05mm)Width100-2000mmSpecification1000*2000/L,1219*2438/L,1500*3000/L,1500*6000/L

Contact Now

310 stainless-steel hex bar may be categorically said that metal bars are one of the middle components of any manufacturing industry or for that matter any industry that is based on machineries.

Contact Now