DN 32 40 50 100 150 200 250 300 ANSI GB Forged Stainless Steel Blind FlangeItemDescriptionBasic InformationMaterial GradeWP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etcSize1/2" to 48" Sch 5S to XXSStandardASTM A403 etc .Process MethodForged / CastingIndustry & AdvantageApplicationa) Connect pipesAdvantagea) High technology ; good surface ; high quality etcTerms & ConditionsPrice ItemFOB , CFR , CIF or as negotiationPaymentT / T , LC or as negotiationDelivery Ti

Contact Now

Internal Stainless steel forged thread flangeThe threaded flanges are connected to the ends of the two pipes, and each flange is installed.

Contact Now

EN1092-1 TYPE02 ISO9001 Standard Stainless Steel 316L 304 321 904 201 Forged Loose FlangeItemDescriptionBasic InformationMaterial GradeWP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etcSize1/2" to 48" Sch 5S to XXSStandardASTM A403 etc .Process MethodForged / CastingIndustry & AdvantageApplicationa) Connect pipesAdvantagea) High technology ; good surface ; high quality etcTerms & ConditionsPrice ItemFOB , CFR , CIF or as negotiationPaymentT / T , LC or as negotiat

Contact Now

Specification of stainless steel rod: From 1.0mm to 250mm size (diameter, side length, thickness or opposite side distance) not more than 250mm hot rolled and forged stainless steel rod.Stainless steel rod material :304, 304L, 321, 316, 316L, 310S, 630, 1Cr13, 2Cr13, 3Cr13, 1Cr17Ni2, duplex steel, antibacterial steel and other materials!TechniqueForged/Hot Rolled/Cold Drawn/PeeledCategory1.Round bar1)Hot rolled black bar: (5-400)x6000mm or according to your requirement.2)Acid round bar: (5-400)x6000mm or according to your requirement.3)Cold drawn bright bar: (1-20)x6000mm or according to your

Contact Now

Flat Welded Flange With Neck XINYUAN has been engaged in theStainless steel production and supply of various flanges and pipe fittings for more than 15 years. Our flagship products include pipes, flanges, elbows, elbows, tees, reducers, caps, forged fittings, bolts and nuts, washers, profiles and other fittings that meet all national and internationally recognized standards.

Contact Now

ApplicationWidely used in petroleum,foodstuff,chemical industry,construction, electricProduct Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines, blades, powder and engines,etcFeatureHigh corrosion resistance, low d

Contact Now

S32760 Super Duplex Forged Bar can be produced by following specification standard ASTM A276.Product Parameter:Stainless Steel barMaterial200 series: 201,202,202Cu,204Cu,300 series: 301, 303/Cu, 304/L/H, 304Cu, 305, 309/S, 310/S, 316/L/H/Ti, 321/H, 347/H, 330,400 series: 409/L, 410, 416/F, 420/F, 430, 431, 440C, 441, 444, 446,600 series: 13-8ph, 15-5ph, 17-4ph, 17-7ph(630,631), 660A/B/C/D,Duplex: 2205(UNSS31803/S32205), 2507(UNSS32750), UNSS32760, 2304, LDX2101.

Contact Now

Section shrinkage ψ(%):134 degrees, aging ≥ 61Density melting point for Young's modulus and Poisson's ratio, yield strength, tensile strength, elongationProduct Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turb

Contact Now

Application:Widely used in petroleum,foodstuff,chemical industry,construction, electricProduct Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines, blades, powder and engines,etcFeatureHigh corrosion resistance, low

Contact Now

Alloy X-750 exhibits excellent oxidation resistance to combustion gases at ambient temperatures up to 1600°F(870°C).Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines, blades, powder and engines,etcFeatureHi

Contact Now

Application field:(1)instrument transformerd(2)rader pulse transformers(3)Transducers(4)Shielding(5)tape recorder head laminations and so onProduct Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines, blades, powder

Contact Now

HASTELLOY C-2000 The most versatile performanceCorrosion-resistant alloy with excellent uniform corrosion resistance in both oxidizing and reducing environments.Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turb

Contact Now

Incoloy 330 is a nickel-ferrichrome austenite alloy.specifically designed for antioxidant and carburizing effects in high-temperature environments.Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines

Contact Now

ncoloy617/alloy617 alloy processing and welding properties: the alloy is easy to process in a variety of hot and cold processing, although due to the high strength, high-power equipment is required. Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180

Contact Now

Alloy 400 (UNS N04400) is a single-phase solid-solution nickel-copper alloy with excellent corrosion resistance to a wide range of media.Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines, blades, powder and

Contact Now

Monel 400 Round BarsMonel 400 Round Bar is a ductile, nickel-copper based totally alloy comprised in truth of two-thirds nickel and one 1/3 copper. Nickel Alloy four hundred is recognised for resistance to a range of corrosive conditions, together with alkalies (or acid like substances), saltwater, hydrofluoric acid and sulfuric acid.

Contact Now

Alloy A286 features high strength, oxidation resistance, and corrosion resistance at continuously high temperatures. A286 alloys are heat treatable to achieve a wide variety of grain structures and tensile properties. This grade of A286 is annealed and aged. Applications for Alloy A286 include jet engine components, superchargers, turbine wheels and blades, fasteners, springs, and general high-stress components in petrochemical, aerospace, and oil patch industries.DetailsA286 is an iron-nickel-chromium alloy with additions of molybdenum and titanium.

Contact Now

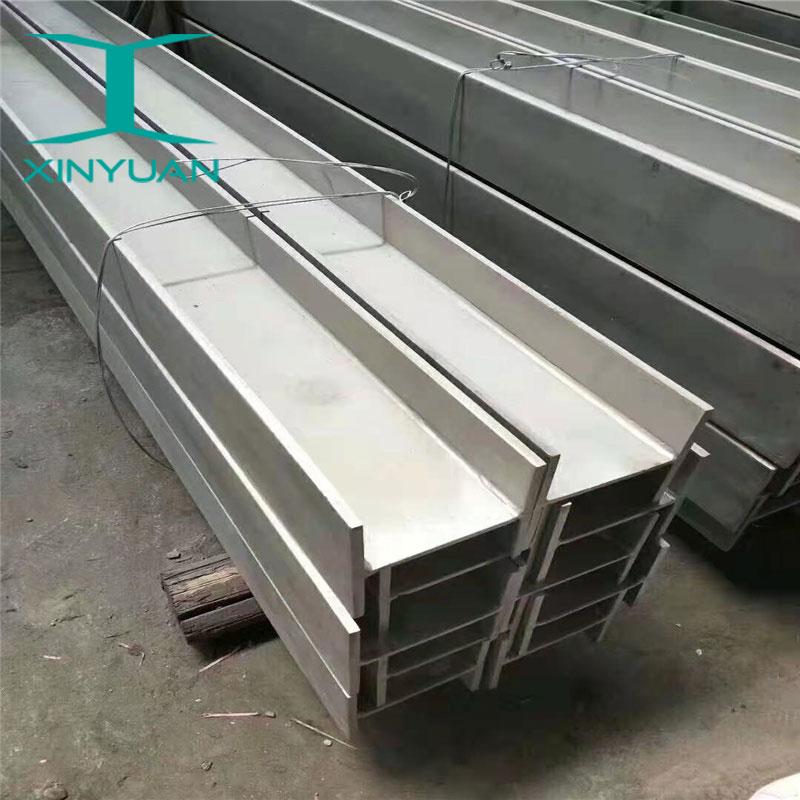

Stainless steel is available in many varieties, each of which suits varying applications. Some key properties that make 316 stainless steel the optimal choice for use in structural beams include its:Corrosion resistance.316 stainless steel is well-suited for building structures in marine or moist environments.

Contact Now

316 stainless steel chemical composition:C≤0.08, Si≤1.00, Mn≤2.00, P≤0.035, S≤0.03, Ni:10.0-14.0, Cr:16.0-18.5, Mo:2.0-3.0.

Contact Now

Alloy 625 exhibits excellent corrosion resistance in many media.

Contact Now

HASTELLOY C-4 alloy has exceptional resistance to wide variety of chemical process environments.

Contact Now

Heat treatment can’t be used to harden this metal. In order to achieve tensile strength and hardness, cold working must be done. When cold working is used, slight magnetism may occur. It is very common for 304 steel to be used for parts that require grinding, welding, polishing and machining, along with corrosion resistance. Because of its ability to handle corrosive environments, it is considered a general all-purpose grade of steel. It is commonly used in chemical industries and for cryogenic services.

Contact Now

Austenitic stainless steel refers to stainless steel with an austenitic structure at room temperature. When the steel contains about 18% Cr, 8%-25% Ni, and about 0.1% C, it has a stable austenite structure. Austenitic chromium-nickel stainless steel includes the famous 18Cr-8Ni steel and the high Cr-Ni series steel developed by adding Cr and Ni content and adding Mo, Cu, Si, Nb, Ti and other elements on this basis. Austenitic stainless steel is non-magnetic and has high toughness and plasticity, but its strength is low. It is impossible to strengthen it through phase transformation.

Contact Now

Alloy 420 can be hardened by cold working and by heat treating.

Contact Now