a182 f304l f316l stainless steel pipe fitting loose flangeItemDescriptionBasic InformationMaterial GradeWP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etcSize1/2" to 48" Sch 5S to XXSStandardASTM A403 etc .Process MethodForged / CastingIndustry & AdvantageApplicationa) Connect pipesAdvantagea) High technology ; good surface ; high quality etcTerms & ConditionsPrice ItemFOB , CFR , CIF or as negotiationPaymentT / T , LC or as negotiationDelivery Time 30 workin

Contact Now

Pipe Fitting Direct: Spectacle Blind Flange 3-1/2'' 600LB Stainless Steel 304L 321 316l ASTM A105 ASME B16.9 Eight 8 Word FlangesItemDescriptionBasic InformationMaterial GradeWP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etcSize1/2" to 48" Sch 5S to XXSStandardASTM A403 etc .Process MethodForged / CastingIndustry & AdvantageApplicationa) Connect pipesAdvantagea) High technology ; good surface ; high quality etcTerms & ConditionsPrice Item

Contact Now

sus304 sus316L sanitary stainless steel pipe fitting 90 180 degree welding elbowProduct Description of Stainless Steel ElbowPIPE FITTINGSProduction Name45 / 90 / 180 , Long / Short Radius Elbows, Equal / Reducing Crosses, Concentric / Eccentric Reducers, Caps, Stub EndsSize RangeFrom ½" up to 72" From 1/2 to 30 (Seamless Pipe Fittings),Form16to 72(Seam Pipe Fittings)ScheduleSCH STD, XS,

Contact Now

90 Degree Wp304/304L/347H/310S/321 Stainless Steel Pipe Fitting Elbow for ConstructionProduct Description of Stainless Steel ElbowPIPE FITTINGSProduction Name45 / 90 / 180 , Long / Short Radius Elbows, Equal / Reducing Crosses, Concentric / Eccentric Reducers, Caps, Stub EndsSize RangeFrom ½" up to 72" From 1/2 to 30 (Seamless Pipe Fittings),Form16to 72(Seam Pipe Fittings)ScheduleSCH STD, XS,

Contact Now

Gas Fitting Bw 24 90 Degree Elbow Stainless Steel Seamless Pipes And FittingsProduct Description of Stainless Steel ElbowPIPE FITTINGSProduction Name45 / 90 / 180 , Long / Short Radius Elbows, Equal / Reducing Crosses, Concentric / Eccentric Reducers, Caps, Stub EndsSize RangeFrom ½" up to 72" From 1/2 to 30 (Seamless Pipe Fittings),Form16to 72(Seam Pipe Fittings)ScheduleSCH STD, XS, XXS

Contact Now

The grade of austenitic stainless steel is versatile and is widely used stainless steel. It is exhibiting high corrosion resistance for the wide range of highly corrosive environments. The type 304 and 304L stainless steel grade pipe is also exhibiting good machinability and is also having excellent weldability feature without or by adding the filler metals.Stainless Steel 304/304L Pipe & Tube is versatile stainless steel which is popularly used for making the tools or the parts that require excellent performance (formability and corrosion).

Contact Now

304 Stainless Steel Pipe304 is an austenitic alloy, which is made up major constituents of nickel and chromium. The Stainless Steel 304 Pipe is designed with high corrosion and oxidation resistance properties. These alloys have excellent formation as well as welding properties.

Contact Now

Alloy 420 can be hardened by cold working and by heat treating.

Contact Now

Austenitic stainless steel refers to stainless steel with an austenitic structure at room temperature. When the steel contains about 18% Cr, 8%-25% Ni, and about 0.1% C, it has a stable austenite structure. Austenitic chromium-nickel stainless steel includes the famous 18Cr-8Ni steel and the high Cr-Ni series steel developed by adding Cr and Ni content and adding Mo, Cu, Si, Nb, Ti and other elements on this basis. Austenitic stainless steel is non-magnetic and has high toughness and plasticity, but its strength is low. It is impossible to strengthen it through phase transformation.

Contact Now

Alloy 400 from NeoNickel has superb corrosion resistance, particularly in neutral and alkaline salts. It is also one of a limited number of alloys that can be used in conjunction with hydrofluoric acid and fluorine. With high nickel content, this alloy is immune to chloride-induced stress corrosion cracking.

Contact Now

718 Nickel-based alloyProduct description718 Nickel-based alloy is specifically γ '[ Ni3(Al, Ti, Nb)] Nickel based high temperature alloys with getting older reinforcement have proper corrosion resistance and oxidation performance beneath 980 °C, excessive strength below 800 °C, and proper rest resistance underneath 540 °C.

Contact Now

Alloy 718 (UNS N07718) is a high-strength, nickel-based superalloy made for long-term use in temperatures ranging from cryogenic up to 1200°F.

Contact Now

The alloy is resistant to high temperature corrosion properties such as oxidation and carbonization. The alloy is *** resistant to corrosion in hot corrosion areas such as sulfide environments, especially oxidation and carbonization up to 1100°C cycles. These corrosion resistance coupled with excellent mechanical properties make this alloy particularly suitable for high temperature applications.

Contact Now

Alloy K-500 (UNS N05500) is a nickel-copper alloy.

Contact Now

304 stainless steel rectangular tube performance advantages:1. The stainless steel pipe made of 304 material is very environmentally friendly, safe and reliable.2. 304 stainless steel pipe can be bent with high Gini performance to a large extent,3. The 304 stainless steel pipe has excellent resistance to strong acid and alkali corrosion. There is a very thin protective film on the outer surface of the stainless steel pipe, which is very hard. Quickly carry out reconstruction, and it is not easy to have rust.4.

Contact Now

304 Stainless Steel PIpe is a universal stainless steel, which is widely used in the manufacture of equipment and parts requiring good comprehensive properties (corrosion resistance and formability). To maintain the corrosion resistance inherent in stainless steel, the steel must contain at least 18% chromium and at least 8% nickel.

Contact Now

Monel K500 Round BarMonel K500 Round Bar is a age hardened alloy, whose basic composition makeup consists of elements like Nickel&Copper. Which combines the corrosion resistance of Alloy 400 with the high strength, fatigue resistance and erosion resistance.Monel K500 is a nickel-copper alloy, precipitation hardenable through additions of aluminium and titanium. Monel K500 has excellent corrosion resistant characteristics.

Contact Now

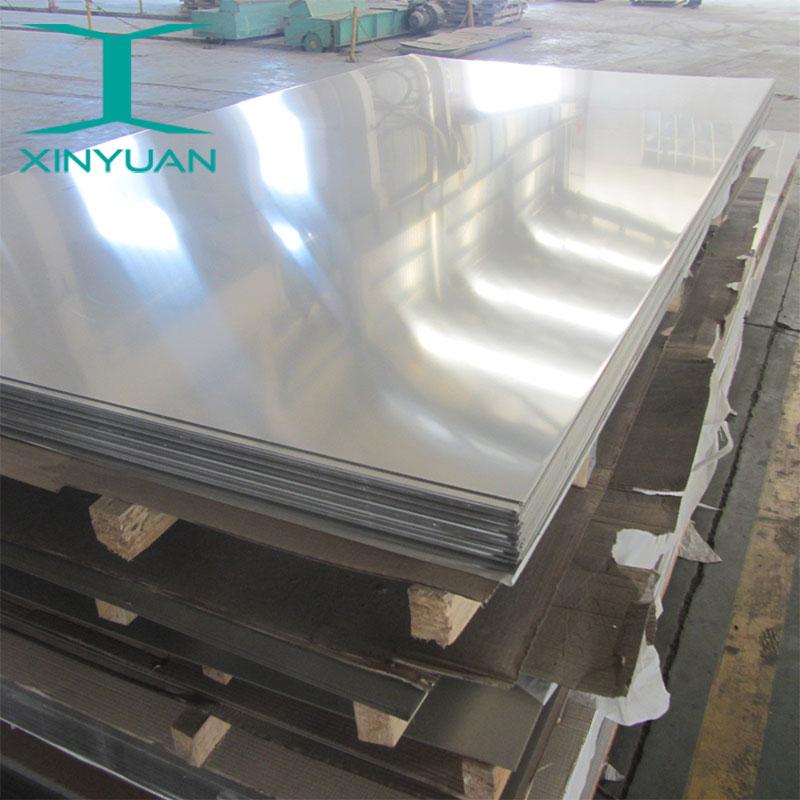

TypeNickel Alloy Sheet/PlateThickness0.8-36mmLength3000mm, 5800mm, 6000mm,etcWidth1000mm,1500mm,2000mm,etcStandardASTM,AISI,JIS,DIN,ENApplicationConstruction,Ship,Boiler,Machinery,etcCertificationISO,SGS,TUVTechniqueCold Rolled/Hot RolledEdgeMill Edge/ Silt EdgeGradeHastelloy: Hastelloy B/ -2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g;etcInconel 600/601/602CA/617/625/713/718/738/X-750;ETCIncoloy: Incoloy 800/800H/800HT/825/925/926;etcGH: GH2132,GH3030,GH3039,GH3128,GH4180,GH3044,etcMonel: Monel 400/K500/R405,etcNitronic 40/50/60/75/80A/90/A263 ;etcSpecificationWire: 0.01-10mm /Strip: 0.05*5.0-

Contact Now

Monel 400 Inconel 600 601 625 718 750 X-750 N07750 4x8 Feet Stainless Steel Sheet/plate Price Per KgTypeNickel Alloy Sheet/PlateThickness0.8-36mmLength3000mm, 5800mm, 6000mm,etcWidth1000mm,1500mm,2000mm,etcStandardASTM,AISI,JIS,DIN,ENApplicationConstruction,Ship,Boiler,Machinery,etcCertificationISO,SGS,TUVTechniqueCold Rolled/Hot RolledEdgeMill Edge/ Silt EdgeGradeHastelloy: Hastelloy B/ -2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g;etcInconel 600/601/602CA/617/625/713/718/738/X-750;ETCIncoloy: Incoloy 800/800H/800HT/825/925/926;etcGH: GH2132,GH3030,GH3039,GH3128,GH4180,GH3044,etcMonel: Monel

Contact Now

Monel 400 PlateMonel 400 Plate is a copper-nickel base alloy plate. Along with these, it is traced with the quantity of manganese, silicon, and carbon content. These Monel 400 Plates have proper ductility and facilitate most suitable resistance to a extensive vary of corrosive circumstances. These plates show off terrific resistance to alkaline and acidic environment. However, it posses extraordinary thermal conductivity in annealed conditions. This grade of plates consists of excessive tensile energy and toughness.

Contact Now

Manufacturer Alloy 330 Incoloy 330 nickel alloy sheet/plate/coilTypeNickel Alloy Sheet/PlateThickness0.8-36mmLength3000mm, 5800mm, 6000mm,etcWidth1000mm,1500mm,2000mm,etcStandardASTM,AISI,JIS,DIN,ENApplicationConstruction,Ship,Boiler,Machinery,etcCertificationISO,SGS,TUVTechniqueCold Rolled/Hot RolledEdgeMill Edge/ Silt EdgeGradeHastelloy: Hastelloy B/ -2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g;etcInconel 600/601/602CA/617/625/713/718/738/X-750;ETCIncoloy: Incoloy 800/800H/800HT/825/925/926;etcGH: GH2132,GH3030,GH3039,GH3128,GH4180,GH3044,etcMonel: Monel 400/K500/R405,etcNitronic 40/50/60/7

Contact Now

The chemical composition of Monel400 alloy is mainly composed of 30%Cu and 65%Ni plus a small amount of Fe(1%-2%). The structure is typical monophasic austenite.

Contact Now

Monel 400 Round BarsMonel 400 Round Bar is a ductile, nickel-copper based totally alloy comprised in truth of two-thirds nickel and one 1/3 copper. Nickel Alloy four hundred is recognised for resistance to a range of corrosive conditions, together with alkalies (or acid like substances), saltwater, hydrofluoric acid and sulfuric acid.

Contact Now

Application field:(1)instrument transformerd(2)rader pulse transformers(3)Transducers(4)Shielding(5)tape recorder head laminations and so onProduct Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines, blades, powder

Contact Now