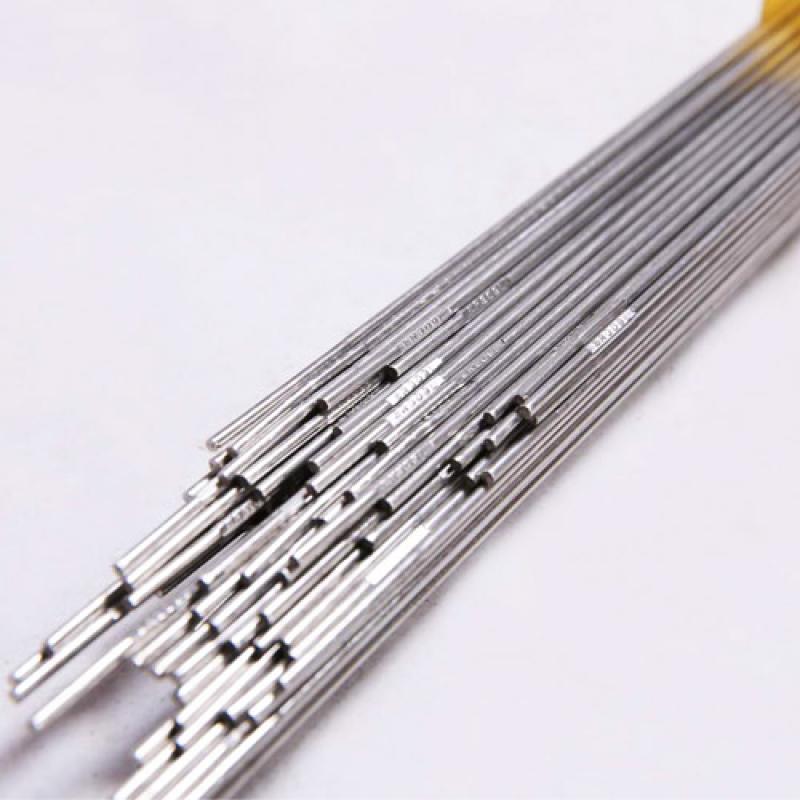

E308L-16 Stainless Steel ElectrodesUses: E308L-16 Stainless Steel Electrodes Used for welding gadget of urea, artificial fiber, and many others.

Contact Now

Available SizesDiameter X Spool SizesDiameter X Coil Sizes.025 x 2#, 10#, 25#1/16 x 60# & mill coil.030 x 2#, 10#, 25#, 30#, 33#5/64 x 60# & mill coil.035 x 2#, 10#, 25#, 30#, 33#3/32 x 60# & mill coil.045 x 2#, 10#, 25#, 30#, 33#1/8 x 60# & mill coil1/16 x 10#, 25#, 30#, 33#3/16 x 60# & mill coil5/32 x 60# & mill coilApplicationWW308 is used to MIG, and submerged arc welding of un-stabilized stainless steels such as Types 301, 302, 304, 305, 308.

Contact Now

430 stainless steel is a type of ferritic stainless-steel that consists of chromium, which gives it its corrosion-resistant properties. the primary alloying element in 430 stainless-steel is chromium, generally starting from 16 to 18 percentage. it additionally has a low carbon content material, which improves its weldability.430 stainless-steel bars are generally utilized in various packages due to their desirable mixture of corrosion resistance, formability, and affordability.

Contact Now

Grade 316 is also primarily composed of iron, and again contains significant amounts of nickel and chromium¡ª10-14% and 16-18%, respectively¡ªand small amounts of carbon, manganese, molybdenum, and silicon.

Contact Now

ER308,ER308L,ER308Si,ER308LSi,ER309,ER309L,ER310,ER316,ER316L;AWS: A5.9Conforms to Certification: AWS A5.9 ASME SFA A5.9Weld Process Used for Mig (GMAW) and Submerged Arc (SAW)AWS Chemical CompositionC = 0.08 maxCr = 19.5 – 22.0Ni = 9.0 – 11.0Mo = 0.75 maxMn = 1.0 – 2.5Si = 0.30 – 0.65P = 0.03 maxS = 0.03 maxCu = 0.75 maxAvailable SizesDiameter X Spool SizesDiameter X Coil Sizes.025 x 2#, 10#, 25#1/16 x 60# & mill coil.030 x 2#, 10#, 25#, 30#, 33#5/64 x 60# & mill coil.035 x 2#, 10#, 25#, 30#, 33#3/32 x 60# & mill coil.045 x 2#, 10#, 25#, 30#, 33#1/8 x 60# & mi

Contact Now

Incoloy 825 Pipe is used in tank trucks, calories, electrostatic precipitator electrodes, chemical process equipment, phosphoric acid evaporators, and sulfuric acid piping and vessels. Moreover, Alloy 825 Welded Pipe is also used in hot vessels for food and water, pickling tank heaters, pickling tanks, ammonium sulfate vessels, expansion bellows, and marine exhaust systems. Alloy 825 Clad Pipe manufactured by us are supplied to various industries in different countries.

Contact Now

The machinability of grade 202 stainless steel produces long, gummy chips. Machining can also be performed in the annealed condition. For heat treatment, the material has to be soaked at 1038°C (1900°F) for 30 min and cooled below 16°C (60°F) for full martensite transformation. The material can be welded by common fusion and resistance methods; however, this steel should not be joined using oxyacetylene welding method. The recommended filler metal is AWS E/ER630. Forging can be done by pre-soaking for 1 h at 1177°C (2150°F).

Contact Now

Product Parameter:Product Namess304 316 904l 201 stainless steel beam I profileSize10#-63C#TechniqueHot Rolled Welded BendingSurfaceNO.1 NO.4 BrightApplicationBuilding /Construction/Steel FrameMaterial201,202,301,304,321,316,316L,etcDelivery FormAccording to Customer Size and StandardSectional DimensionKg/mSectional DimensionKg/m100*50*5*79.54344*354*16*16131100*100*6*817.2346*174*6*941.8125*60*6*813.3350*175*7*1150125*125*6.5*923.8344*348*10*16115148*100*6*921.4350*350*12*19137150*75*5*714.3388*402*15*15141150*150*7*1031.9390*300*10*16107175*90*5*818.2394*398*11*18147175*175*7.5*1140.3400*150

Contact Now

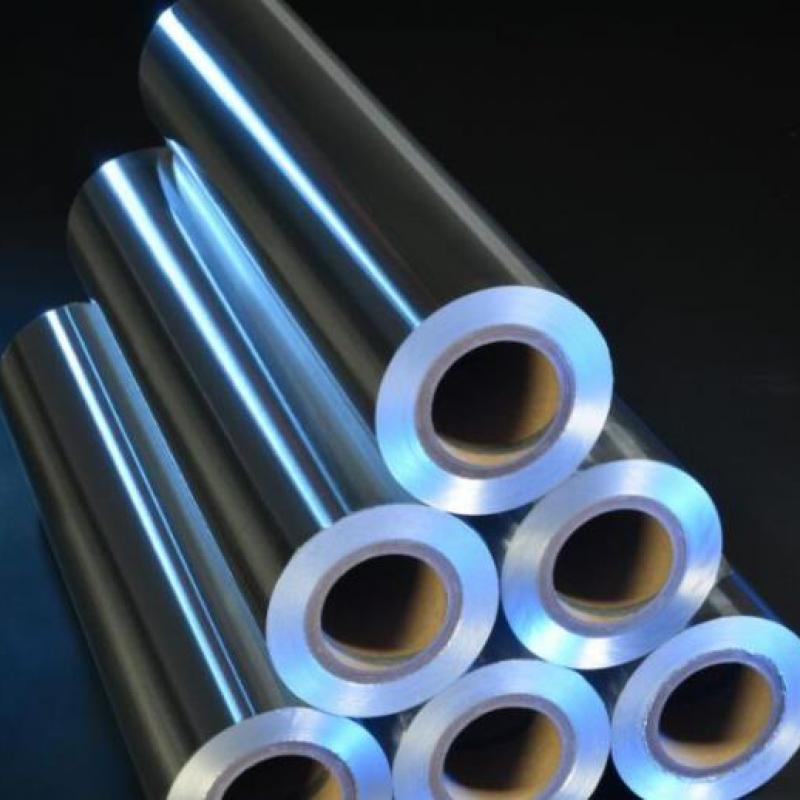

Through integrated production control, stainless steel foil that is excellent in etching properties and press formability, in addition to ultimately high thickness accuracy, strength, and spring characteristics. Stainless Steel FoilStainless steel foil is produced through the highly accurate rolling of stainless steel to be as thin as 100 mm, thus it has excellent flexibility, lightweight characteristics, and corrosion resistance.

Contact Now

Applications.Chemical industry involving phosphoric acid, sulfuric acid and nitric acid, nuclear fuel reprocessing, nuclear waste treatment, acid washing, petrochemicals, fertilizer manufacturing, pesticide manufacturing, gold extraction, etc. Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm

Contact Now

According to the main chemical composition is divided into chromium stainless steel, chromium nickel stainless steel and chromium manganese nitrogen stainless steel; Can also be divided into acid resistant stainless steel and heat resistant stainless steel with performance characteristics; It is usually classified by metallographic structure.

Contact Now

Section shrinkage ψ(%):134 degrees, aging ≥ 61Density melting point for Young's modulus and Poisson's ratio, yield strength, tensile strength, elongationProduct Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turb

Contact Now

410 Stainless Steel Checker Plate410 stainless steel contains 0.15% carbon and 13% chromium. It is a semi martensitic stainless steel. After quenching and tempering, it has high strength and toughness. It has good corrosion resistance and machining performance in a weak corrosive medium with a temperature not exceeding 30 degrees. It also has rust and corrosion resistance in wet atmosphere and fresh water, and has high thermal stability below 700 ℃.

Contact Now

Our stainless steel plates can be used for the following range of applicationsChemical industriesOil & GasAviation & AerospacePetrochemicalsPharmaceuticalsWe provide high and fine focus plasma, waterjet & laser cutting.304/1.403 Stainless6 mm8 mm10 mm12 mm14 mm15 mm16 mm18 mm20 mm22 mm25 mm28 mm30 mm32 mm35 mm36 mm40 mm45 mm50 mm55 mm60 mm65 mm70 mm75 mm80 mm90 mm100 mm110 mm120 mm130 mm150 mm 304L/1.4307 stainless6 mm8 mm10 mm12 mm14 mm15 mm16 mm18 mm20 mm22 mm25 mm28 mm30 mm32 mm35 mm36 mm40 mm45 mm50 mm55 mm60 mm65 mm70 mm75 mm80 mm90 mm100 mm110 mm120 mm130 mm150 mm 3

Contact Now

ApplicationWidely used in petroleum,foodstuff,chemical industry,construction, electricProduct Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines, blades, powder and engines,etcFeatureHigh corrosion resistance, low d

Contact Now

Application field:(1)instrument transformerd(2)rader pulse transformers(3)Transducers(4)Shielding(5)tape recorder head laminations and so onProduct Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines, blades, powder

Contact Now

Application:Widely used in petroleum,foodstuff,chemical industry,construction, electricProduct Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines, blades, powder and engines,etcFeatureHigh corrosion resistance, low

Contact Now

304 is a universal stainless steel, which is widely used in the manufacture of equipment and parts requiring good comprehensive properties (corrosion resistance and formability). To maintain the corrosion resistance inherent in stainless steel, the steel must contain at least 18% chromium and at least 8% nickel.

Contact Now

Alloy X-750 exhibits excellent oxidation resistance to combustion gases at ambient temperatures up to 1600°F(870°C).Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines, blades, powder and engines,etcFeatureHi

Contact Now

Type 301 is a chromium nickel austenitic stainless steel capable of attaining high strengths and ductility by cold working. It is not hardenable by heat ...Type 301 is corrosion resistant in many environments, but the corrosion properties are less than that of 304/304L stainless steel.

Contact Now

Stainless Steel Butt Weld ElbowPackaging Details:Standard seaworthy package or as your requiredPort :Tianjin or as your requiredProducts DescriptionProduct NameANSI B16.9 Butt Weld Stainless Steel 90 Degree LR ElbowSize1/2"-48"MaterialStainless SteelPackagingWooden Case/Wooden PalletsStandardANSI ,ASME, EN,DIN, JISRadiusLong, Short ThicknessSCH5S-SCHXXSOthersSpecial design available according to your requestProduct photoProduct Advantage:1.

Contact Now

AISI 309L Stainless Steel Wire309S stainless steel -- S30908 (American AISI, ASTM) 309S. Most of the steel mills produce 309S stainless steel, which has good corrosion resistance and high temperature resistance. Withstands high temperatures of 980°C. Mainly used in boiler, chemical and other industries.

Contact Now

304 stainless steel is a common stainless steel material, density of 7.93 g/cm³, the industry is also known as 18/8 stainless steel.

Contact Now

Type Stainless Steel SheetThicknessASIS,ASTM,DIN,JIS,JB,SUS,EN,etc.Size1000*2000mm, 1219*2438mm, 1219*3048mm or customized Max.

Contact Now