Stainless Products supplies stainless steel seamless tube per ASTM A 213, ASTM A 269 and ASTM A 511. We supply common grades of stainless steel such as 304/304L and 316/316L in standard tube sizes and wall thicknesses.

Contact Now

Astm A790 Super Duplex 2507 Stainless Steel PipesProduct DescriptionThe chemical composition is :carbon C≤0.15manganese Mn≤1.25silicon Si≤1.00chromium Cr12.0~14.0nickel Ni≤0.60%phosphorus P≤0.06sulfur S≤0.15Molybdenum≤0.60%Product DescriptionProductAstm A790 Super Duplex 2507 Stainless Steel PipesSurface FinishBA, 2B, 2D, 4K, 6K, 8K, NO.4, HL, EmbossedTechniqueHot Rolled / Cold RolledStandardGB JIS ASTM ASME ENSteel Grade200 series: 201 202300 series: 301 304 304L 309 310 310s 316 316L 321400 series: 409 410 410S 420 430ColorStandard RAL color:red,bule,white,grey,brick,etc.Stock Dimension0.5mm

Contact Now

These grades of austenitic stainless steels are the most versatile and widely used stainless steels. They exhibit excellent corrosion resistance to a wide range of corrosive environments.

Contact Now

LDX 2101* is a duplex (austenitic-ferritic) stainless steel with relatively low contents of alloying elements. The grade has high mechanical strength, similar to that of other duplex grades. Its good corrosion resistance is on par with that of most standard stainless steel grades.

Contact Now

Product SpecificationUnit Pipe Length3 meter, 6 meter, 9 meter, 18 meterMaterialStainless SteelProduct DescriptionGradeTensileUltimate/MinYield/MinElongation/Min-KSIMPAKSIMPA%304755153020535304L704852517035These grades of austenitic stainless steels are the most versatile and widely used stainless steels.

Contact Now

304 (UNS S30400, 1.4301) stainless steel is a universal stainless steel, it is widely used to make equipment and machine parts that require good comprehensive performance. In order to maintain the inherent corrosion resistance of stainless steel, the steel must contain more than 18% chromium and more than 8% nickel content. 304 stainless steel is a grade of stainless steel produced in accordance with the American ASTM standard.The most important elements in 304 stainless steel are Ni and Cr, but they are not limited to these two elements.

Contact Now

AISI 329 Duplex Stainless Steel Plate belongs to a specification of duplex steel grades.

Contact Now

UNS S32760 is able to compete strongly with the 6% molybdenum “super austenitic” grades in some applications, as it has fewer amounts of Mo and Ni which drive up the base cost of the material. Although, 32760 has lower amounts when compared to “6% Moly” grades it still has higher contents of Cr, Ni, and Mo when referring to other alloys, these elements improve the intergranular and pitting corrosion resistance of the material.

Contact Now

Features of STAINLESS STEEL PipeOuter Diameter10-2000mm or as customer's requirementsThickness0.1-100mm or as customer's requirementsLength1000-12000mm or as requirementsSurfaceN0.1, N0.4, 2D, 2B, HL, BA, 6K, 8K, Mirror,etcMaterial201,202,301,302,303,304,304L,304N1,309S,310S,316,316L,316Ti,316N,317,317L,321,409L,410,420,430,904,904L,etcGrade200/300/400/500/600/700/800/900 series/duplex stainless steelStandardsAISI ASTM JIS SUS DIN GBCertificationsISO 9001 and SGSPackingIndustry standard packaging or according to client's requirementBrandTISCO,ZPSS,Baosteel,POSCO,LISCO,YUSCO,Ansteel

Contact Now

ASTM Decorative tube A312 201 304 304L 316 316L 430 904 2205 Sch10 2mm Thick hardness Polished bright Stainless Steel Bright Hairline Round square PipeDescriptionItemASTM Decorative tube A312 201 304 304L stainless steel pipeSteel grade300 seriesStandardASTM A213,A312,ASTM A269,ASTM A778,ASTM A789,DIN 17456, DIN17457,DIN 17459,JIS G3459,JIS G3463,GOST9941,EN10216, BS3605,GB13296Material304,304L,309S,310S,316,316Ti,317,317L,321,347,347H,304N,316L, 316N,201,904l,2205,2507,254smoSurfacePolishing,annealing,pickling,brightTypehot rolled and cold rolledWe can provide! 1 Reliable quality an

Contact Now

Duplex 2304 is two-phase, ferritic, austenitic which contain chromium 23%,nickel 4%, molybdenum-free duplex stainless steel. Itscorrosion resistance properties are similar to 316L stainless steel. Furthemore it has mechanical properties twice to 304L stainless steel/316Lstainless steel grades. And this becomes helpful for the manufacturers to save weight especially for properly designed pressure vessel applications.

Contact Now

2205 Duplex Stainless Steel PlateDuplex 2205 is a two-phase, ferritic, austenitic 22% chromium, 3% molybdenum, 5 to 6% nickel alloyed stainless steel. It is the most widely used duplex stainless steel grade and is characterized by high yield strength, double that of the standard austenitic stainless steel grades.

Contact Now

2205 duplex stainless steel Pipe SpecificationItemStainless Steel Tube/PipeSteel grade200series,300 series,400series,duplexStandardASTM A213,A312,ASTM A269,ASTM A778,ASTM A789,DIN 17456,DIN17457,DIN 17459,JIS G3459,JIS G3463,GOST9941,EN10216,BS3605,GB13296Material304,304L,309S,310S,316,316Ti,317,317L,321,347,347H,304N,316L, 316N,201,202,2205,2507,904lSurfacePolishing,annealing,pickling,brightTypehot rolled and cold rolledstainless steel round pipe/tubeSizeWall thickness1mm-150mm(SCH10-XXS)Outer diameter6mm-2500mm (3/8"-100")stainless steel square pipe/tubeSizeWall thickness1mm-150mm(

Contact Now

Duplex 2205 PlateDuplex 2205 Plate is a two-phase, ferritic, austenitic 22% chromium, 3% molybdenum, 5 to 6% nickel alloyed stainless steel. Duplex 2205 Plate is the most broadly used duplex stainless metal grade and is characterised via excessive yield strength, double that of the standard austenitic stainless steel grades.

Contact Now

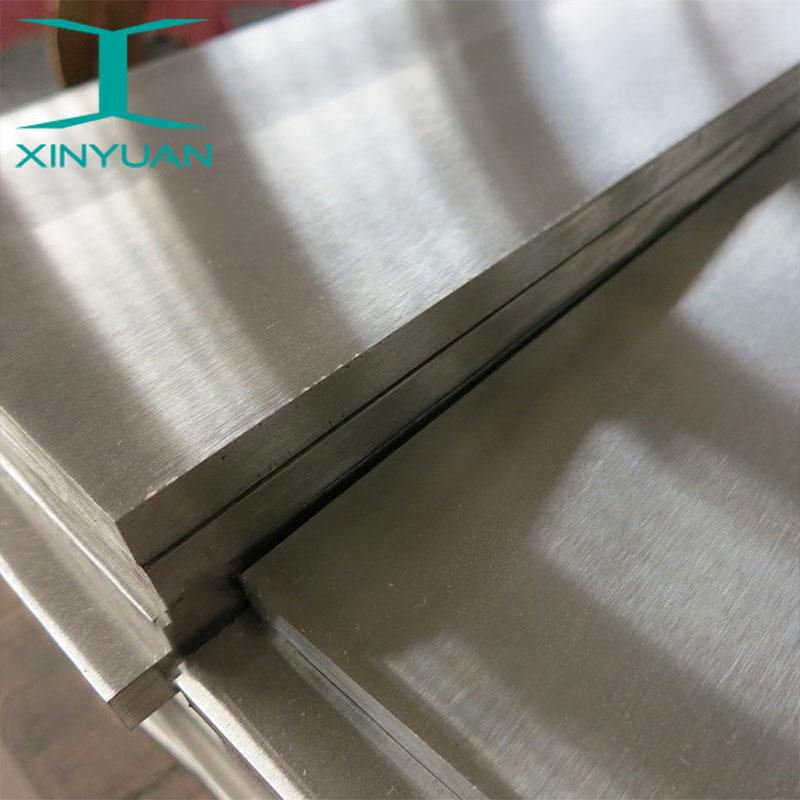

Stainless steel sheet is available in kind 304 and sort 316. type 304 may be easily roll-formed or bent, and its incredible corrosion resistance and weldability make it one of the maximum popular grades. Type 316 is a excessive corrosion resistance alloy, providing extra resistance to pitting-kind corrosion.

Contact Now

Products DescriptionStainless steel is notable for its corrosion resistance, and it is widely used for food handling and cutlery among many other applications.Type 304 can be easily roll-formed or bent, and its excellent corrosion resistance and weldability make it one of the most popular grades. Type 316 is a high corrosion resistance alloy, providing greater resistance to pitting-type corrosion. Typical uses for Type 316 include marine, chemical, paper, textile, and food service applications, such as a stainless steel back splash.

Contact Now

Products DescriptionStainless steel is notable for its corrosion resistance, and it is widely used for food handling and cutlery among many other applications.Stainless steel sheet is to be had in kind 304 and sort 316. type 304 may be without problem roll-original or bent, and its great corrosion resistance and weldability make it one of the maximum famous grades.

Contact Now

Stainless steel bar specification, materialMaterial :304, 304L, 321, 316, 316L, 310S, 630, 1Cr13, 2Cr13, 3Cr13, 1Cr17Ni2, duplex steel, antibacterial steel and other materials!304(18Cr-8Ni) material: as a widely used steel, has good corrosion resistance, heat resistance, low temperature strength and mechanical properties; Stamping, bending and other thermal processing, no heat treatment hardening phenomenon (no magnetic, they use temperature -196℃~800℃).

Contact Now

ASTM A790 refers to stainless steel seamless and welded pipes (UNS S31803, UNS S32205, UNS S32750, UNS S32760). These tubes can be easily cut and molded by bending, stretching, extrusion, and other common procedures. Consideration should be given to its high intensity and the resulting larger springbok.

Contact Now

The main feature is that the yield strength can reach 400-550mpa, which is 2 times of ordinary stainless steel, so it can save material and reduce the cost of equipment manufacturing.

Contact Now

Duplex stainless steel tube has good welding performance, compared with ferritic stainless steel and austenitic stainless steel, it is not like the welding heat affected zone of ferritic stainless steel, because of the severe coarsing grain and the plastic toughness is greatly reduced, nor like austenitic stainless steel, is more sensitive to welding hot crack.Because of its special advantages, duplex stainless steel is widely used in petrochemical equipment, seawater and wastewater treatment equipment, oil and gas pipelines, papermaking machinery and other industrial fields.

Contact Now

ASTM A182 F11 F22 F5 F304 F316L F53 Stainless Steel Duplex Stainless Steel Slip on Flange So RF Flange Weld Neck Flange Blind FlangeItemDescriptionBasic InformationMaterial GradeWP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etcSize1/2" to 48" Sch 5S to XXSStandardASTM A403 etc .Process MethodForged / CastingIndustry & AdvantageApplicationa) Connect pipesAdvantagea) High technology ; good surface ; high quality etcTerms & ConditionsPrice ItemFOB , CFR , CIF or as

Contact Now

Stainless Steel Pipe/Tube Grade 1.4301 ASTM A312 / ASME SA312ItemStainless Steel Tube/PipeSteel grade200series,300 series,400series,duplexStandardASTM A213,A312,ASTM A269,ASTM A778,ASTM A789,DIN 17456,DIN17457,DIN 17459,JIS G3459,JIS G3463,GOST9941,EN10216,BS3605,GB13296Material304,304L,309S,310S,316,316Ti,317,317L,321,347,347H,304N,316L, 316N,201,202SurfacePolishing,annealing,pickling,brightTypehot rolled and cold rolledstainless steel round pipe/tubeSizeWall thickness1mm-150mm(SCH10-XXS)Outer diameter6mm-2500mm (3/8"-100")stainless steel square pipe/tubeSizeWall thickness1mm-150mm(

Contact Now

ASTM A312 pipe is the general use stainless steel pipe applied in different industries. It covers diameters from 1/8” to 30” and thickness from SCH 10S to SCH 80S.

Contact Now