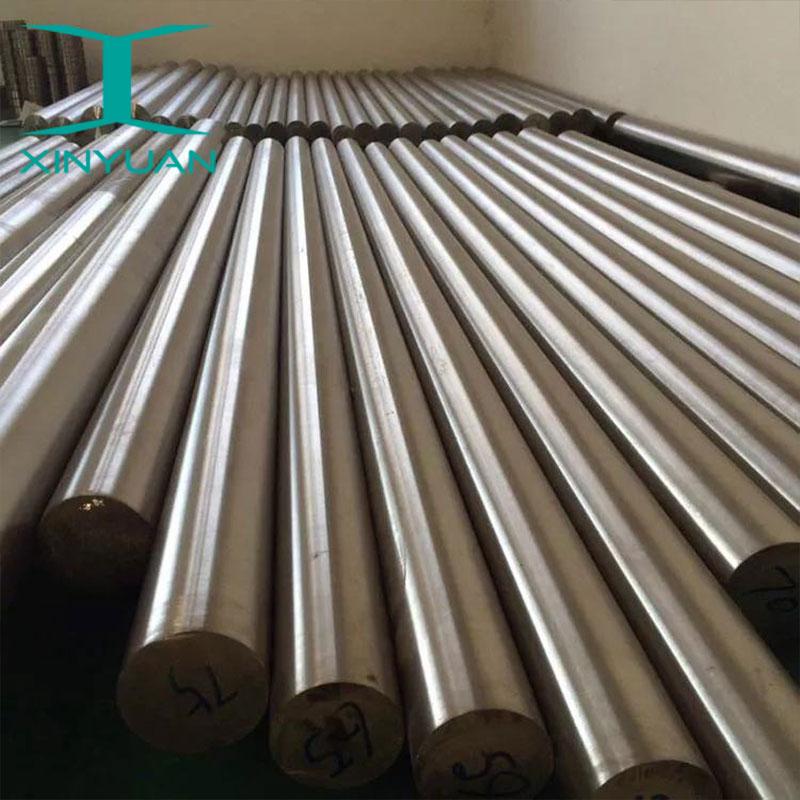

C276 Nickel Base Alloy Bar Hastelloy C-276 CharacterThe key elements influencing corrosion resistance of this fabric are the control of impurity S,P, gascontent O,N and key factors C,Si, and so forth.It depends on the manage of manufacturing procedure, which include thepreference of heating temperature and heat maintenance time of forging, such as the assure of forgingratio, inclusive of the assure of strong answer remedy, and so on.Product Parameter:2.Chemical compositionCSMnPSNiCrMoFeCoWVMin14.515.04.03.0Max0.010.081.00.040.03Mar

Contact Now

It has good corrosion resistance in low and medium temperature hydrochloric acid.

Contact Now

Nickel Base Alloy C276 are tremendous for warmth exchangers inside the chemical processing and nuclear industries. they’re used in steam generator tubing inside the nuclear energy industry, in excessive-temperature aircraft structures, and in oil and fuel extraction packages in which corrosion-, stress- and temperature-resistant tubing is needed.

Contact Now

Incoloy 330 is a nickel-ferrichrome austenite alloy.specifically designed for antioxidant and carburizing effects in high-temperature environments.Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines

Contact Now

Alloy 400 (UNS N04400) is a single-phase solid-solution nickel-copper alloy with excellent corrosion resistance to a wide range of media.Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines, blades, powder and

Contact Now

Types 309 and 309S are austenitic chromium-nickel stainless steels that provide excellent corrosion resistance and heat resistance plus good strength at room and elevated temperatures. Type 309S is identical to Type 309 except for a lower carbon content that minimizes carbide precipitation and improves weldability.

Contact Now

ncoloy617/alloy617 alloy processing and welding properties: the alloy is easy to process in a variety of hot and cold processing, although due to the high strength, high-power equipment is required. Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180

Contact Now

Applications.Chemical industry involving phosphoric acid, sulfuric acid and nitric acid, nuclear fuel reprocessing, nuclear waste treatment, acid washing, petrochemicals, fertilizer manufacturing, pesticide manufacturing, gold extraction, etc. Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm

Contact Now

Application:Widely used in petroleum,foodstuff,chemical industry,construction, electricProduct Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines, blades, powder and engines,etcFeatureHigh corrosion resistance, low

Contact Now

ApplicationWidely used in petroleum,foodstuff,chemical industry,construction, electricProduct Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines, blades, powder and engines,etcFeatureHigh corrosion resistance, low d

Contact Now

HASTELLOY C-2000 The most versatile performanceCorrosion-resistant alloy with excellent uniform corrosion resistance in both oxidizing and reducing environments.Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turb

Contact Now

Section shrinkage ψ(%):134 degrees, aging ≥ 61Density melting point for Young's modulus and Poisson's ratio, yield strength, tensile strength, elongationProduct Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turb

Contact Now

The C276 alloy (UNS N10276) is used in chemical processing, pollution control, pulp and paper production, industrial and municipal waste disposal, and recovery of "sour" natural gas.

Contact Now

Application field:(1)instrument transformerd(2)rader pulse transformers(3)Transducers(4)Shielding(5)tape recorder head laminations and so onProduct Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines, blades, powder

Contact Now

Alloy 625 (UNS NO6625) is used in combustion system transition bushings, propeller blades, seals, fasteners, pumps, turbine rings, heat exchanger tubes, reaction vessels, distillation towers, heat exchangers and valves.Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)

Contact Now

Inconel 825 Nickel Base Alloy Bar high nickel content ensures resistance to stress corrosion cracking, combined with molybdenum and copper to strongly resist reducing environments such as sulphuric and phosphoric acids, chromium to resist oxidising environments such as nitric acid, titanium to inhibit intergranular corrosion, and overall resistance to pitting and crevice corrosion.Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 8

Contact Now

Alloy X-750 exhibits excellent oxidation resistance to combustion gases at ambient temperatures up to 1600°F(870°C).Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines, blades, powder and engines,etcFeatureHi

Contact Now

A 310s stainless-steel bar is a sort of stainless steel alloy that carries high degrees of chromium, nickel, and a mild quantity of carbon. the "310s" designation refers back to the unique grade of stainless-steel and indicates that it contains 25-28% chromium and 19-22% nickel.310s chrome steel is known for its outstanding oxidation resistance at high temperatures and its potential to face up to thermal biking.

Contact Now

This nickel based alloy produced in the form of rounds, squares, hexagons, rectangles as well as Alloy 601 Uns N06601 Cold Finished Bar apart from cold- worked wire, have been covered in the ASTM B166 specification.

Contact Now

A 309s chrome steel bar is a sort of stainless-steel alloy that consists of excessive stages of chromium, nickel, and a moderate amount of carbon. the "309s" designation refers back to the specific grade of stainless-steel and indicates that it consists of 22-24% chromium and 12-15% nickel.309s stainless steel is understood for its excellent excessive-temperature resistance, making it suitable for use in programs that require resistance to oxidation and scaling at increased temperatures.

Contact Now

347h stainless steel bar is a form of stainless-steel alloy that belongs to the austenitic circle of relatives. it includes high stages of chromium, nickel, and small amounts of niobium (columbium) to enhance its resistance to corrosion and high-temperature environments.The "h" in 347h represents the high carbon content material, which affords advanced excessive-temperature power. this stainless steel grade has brilliant mechanical properties, inclusive of high tensile and yield strength.

Contact Now

Bars are the most common raw material used by industries in various shapes and sizes, one such shape of the bar is Alloy 926 Round Bar. The most common shapes of Bars are Alloy 926 Round Bar, Alloy 926 Square Bar, Alloy 926 Rectangle Bar, and Alloy 926 Hex Bar.

Contact Now

201 stainless steel bar is a type of stainless steel that contains low nickel content and higher manganese content. It is a cost-effective option for applications that require corrosion resistance and moderate strength.Some key features of 201 stainless steel bar include:Good corrosion resistance: It offers resistance to atmospheric corrosion, mild acids, and alkalis.Moderate strength: It has lower yield strength and tensile strength compared to other stainless steel grades, such as 304 or 316.201 stainless steel bar is commonly used in various industries such as construction, automotive

Contact Now

C-276 alloy welding performance and common austenitic stainless steel is similar to using a welding method for welding C-276 before, we must take measures to make the corrosion resistance of the weld and heat affected zone the smallest decline, such as tungsten gas shielded arc welding (GTAW), gas metal arc welding (GMAW), submerged arc welding or some other can make the weld and heat affected zone the smallest decline in corrosion resistance welding method.

Contact Now