Alloy K-500 (UNS N05500) is a nickel-copper alloy.

Contact Now

Alloy 718 (UNS N07718) is a high-strength, nickel-based superalloy made for long-term use in temperatures ranging from cryogenic up to 1200°F.

Contact Now

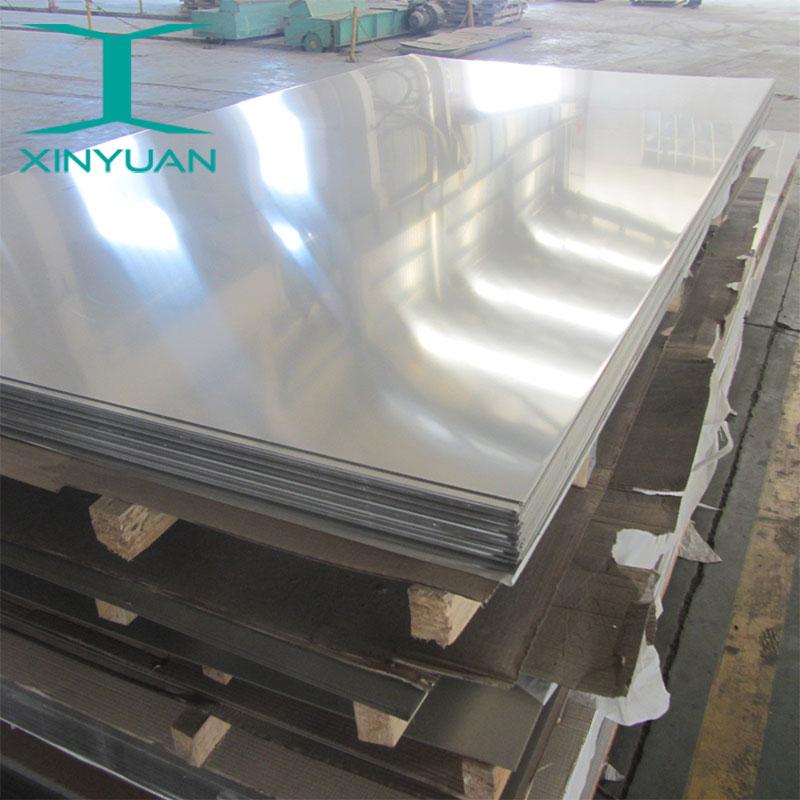

DIN 2.4375/MONEL K-500/UNS N05500 Alloy Steel Plate TypeNickel Alloy Sheet/PlateThickness0.8-36mmLength3000mm, 5800mm, 6000mm,etcWidth1000mm,1500mm,2000mm,etcStandardASTM,AISI,JIS,DIN,ENApplicationConstruction,Ship,Boiler,Machinery,etcCertificationISO,SGS,TUVTechniqueCold Rolled/Hot RolledEdgeMill Edge/ Silt EdgeGradeHastelloy: Hastelloy B/ -2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g;etcInconel 600/601/602CA/617/625/713/718/738/X-750;ETCIncoloy: Incoloy 800/800H/800HT/825/925/926;etcGH: GH2132,GH3030,GH3039,GH3128,GH4180,GH3044,etcMonel: Monel 400/K500/R405,etcNitronic 40/50/60/75

Contact Now

The C276 alloy (UNS N10276) is used in chemical processing, pollution control, pulp and paper production, industrial and municipal waste disposal, and recovery of "sour" natural gas.

Contact Now

The chemical composition of Monel400 alloy is mainly composed of 30%Cu and 65%Ni plus a small amount of Fe(1%-2%). The structure is typical monophasic austenite.

Contact Now

718 Nickel-based alloyProduct description718 Nickel-based alloy is specifically γ '[ Ni3(Al, Ti, Nb)] Nickel based high temperature alloys with getting older reinforcement have proper corrosion resistance and oxidation performance beneath 980 °C, excessive strength below 800 °C, and proper rest resistance underneath 540 °C.

Contact Now

This nickel based alloy produced in the form of rounds, squares, hexagons, rectangles as well as Alloy 601 Uns N06601 Cold Finished Bar apart from cold- worked wire, have been covered in the ASTM B166 specification.

Contact Now

Incoloy 800H Nickel Base Alloy Pipe Application:National defense, astronautics, transportation, equipment manufacture, shipping, petroleum, nuclear power industry, oil and gas industry, and chemical industry etc.Product Parameter:Product NameChina Factory Supplier Nickel Based Alloy Steel Astm B444 Uns N06625 Inconel 625 Din2.4856 Alloy 625 Steel Pipe TubeStandardGB,AISI,ASTM,DIN,EN,JISGradeStainless steel 304 / 304L / 310S / 316L / 316Ti / 316LN / 317L / 904L / 2205 / 2507 / 32760 / 253MA / 254SMo / XM-19 / S31803 /S32750 / S32205 / F50 / F60 / F55 / F60 / F61 / F65 etcMonel 400 / Monel K-500

Contact Now

The alloy is resistant to high temperature corrosion properties such as oxidation and carbonization. The alloy is *** resistant to corrosion in hot corrosion areas such as sulfide environments, especially oxidation and carbonization up to 1100°C cycles. These corrosion resistance coupled with excellent mechanical properties make this alloy particularly suitable for high temperature applications.

Contact Now

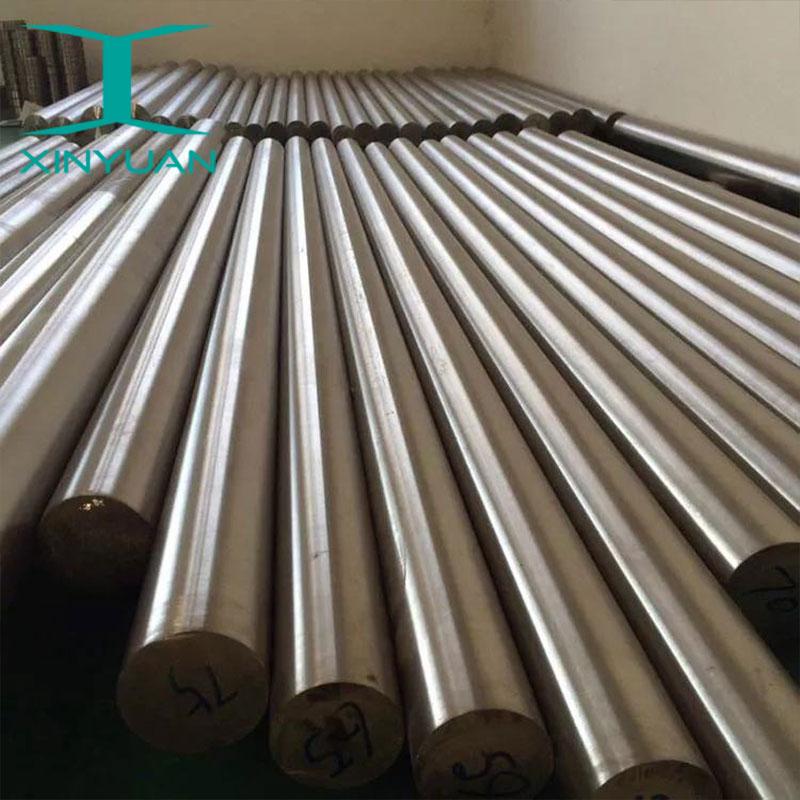

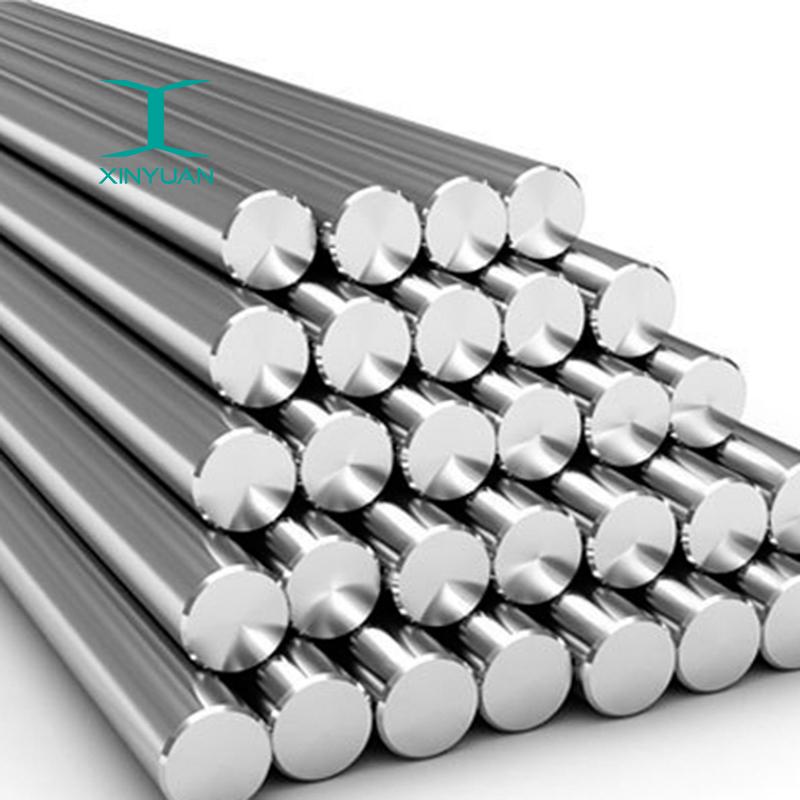

Alloy X-750 exhibits excellent oxidation resistance to combustion gases at ambient temperatures up to 1600°F(870°C).Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180~400mmLengthCustomizedApplicationAuto, turbines, blades, powder and engines,etcFeatureHi

Contact Now

Monel 400 Round BarsMonel 400 Round Bar is a ductile, nickel-copper based totally alloy comprised in truth of two-thirds nickel and one 1/3 copper. Nickel Alloy four hundred is recognised for resistance to a range of corrosive conditions, together with alkalies (or acid like substances), saltwater, hydrofluoric acid and sulfuric acid.

Contact Now

Inconel 617 Pipe & other nickel based alloys from these ranges are ideal for cost-effective manufacture of pumps, valves and process control equipment in oil and gas extraction.Product Parameter:Product NameChina Factory Supplier Nickel Based Alloy Steel Astm B444 Uns N06625 Inconel 625 Din2.4856 Alloy 625 Steel Pipe TubeStandardGB,AISI,ASTM,DIN,EN,JISGradeStainless steel 304 / 304L / 310S / 316L / 316Ti / 316LN / 317L / 904L / 2205 / 2507 / 32760 / 253MA / 254SMo / XM-19 / S31803 /S32750 / S32205 / F50 / F60 / F55 / F60 / F61 / F65 etcMonel 400 / Monel K-500Inconel 600 / Inconel 601 / Inc

Contact Now

Alloy A286 features high strength, oxidation resistance, and corrosion resistance at continuously high temperatures. A286 alloys are heat treatable to achieve a wide variety of grain structures and tensile properties. This grade of A286 is annealed and aged. Applications for Alloy A286 include jet engine components, superchargers, turbine wheels and blades, fasteners, springs, and general high-stress components in petrochemical, aerospace, and oil patch industries.DetailsA286 is an iron-nickel-chromium alloy with additions of molybdenum and titanium.

Contact Now

Outer diameter :10.3mm-406.4mm Wall thickness :1.24mm-40.49mmLength: usually fixed length 6m, according to customer requirementsProduct Parameter:Product NameChina Factory Supplier Nickel Based Alloy Steel Astm B444 Uns N06625 Inconel 625 Din2.4856 Alloy 625 Steel Pipe TubeStandardGB,AISI,ASTM,DIN,EN,JISGradeStainless steel 304 / 304L / 310S / 316L / 316Ti / 316LN / 317L / 904L / 2205 / 2507 / 32760 / 253MA / 254SMo / XM-19 / S31803 /S32750 / S32205 / F50 / F60 / F55 / F60 / F61 / F65 etcMonel 400 / Monel K-500Inconel 600 / Inconel 601 / Inconel 625 / Inconel 617 / Inconel 690 / Inconel 718 /

Contact Now

Product Parameter:Product NameChina Factory Supplier Nickel Based Alloy Steel Astm B444 Uns N06625 Inconel 625 Din2.4856 Alloy 625 Steel Pipe TubeStandardGB,AISI,ASTM,DIN,EN,JISGradeStainless steel 304 / 304L / 310S / 316L / 316Ti / 316LN / 317L / 904L / 2205 / 2507 / 32760 / 253MA / 254SMo / XM-19 / S31803 /S32750 / S32205 / F50 / F60 / F55 / F60 / F61 / F65 etcMonel 400 / Monel K-500Inconel 600/ Inconel 601 / Inconel 625 / Inconel 617 / Inconel 690 / Inconel 718 / Inconel X-750Incoloy A-286 / Incoloy 800 / Incoloy 800H / Incoloy 800HTIncoloy 825 / Incoloy 901 / Incoloy 925 / Incoloy 926Nimon

Contact Now

Incoloy 825 Nickel Base Alloy Pipe the organism is mainly used in heat treatment equipment, resistance alloy tube type heater and covering device, chemical such as petroleum processing equipment.Product Parameter:Product NameChina Factory Supplier Nickel Based Alloy Steel Astm B444 Uns N06625 Inconel 625 Din2.4856 Alloy 625 Steel Pipe TubeStandardGB,AISI,ASTM,DIN,EN,JISGradeStainless steel 304 / 304L / 310S / 316L / 316Ti / 316LN / 317L / 904L / 2205 / 2507 / 32760 / 253MA / 254SMo / XM-19 / S31803 /S32750 / S32205 / F50 / F60 / F55 / F60 / F61 / F65 etcMonel 400 / Monel K-500Inconel

Contact Now

Inconel nickel base alloy 600 625 706 725 seamless hastelloy pipeProduct Parameter:Product NameChina Factory Supplier Nickel Based Alloy Steel Astm B444 Uns N06625 Inconel 625 Din2.4856 Alloy 625 Steel Pipe TubeStandardGB,AISI,ASTM,DIN,EN,JISGradeStainless steel 304 / 304L / 310S / 316L / 316Ti / 316LN / 317L / 904L / 2205 / 2507 / 32760 / 253MA / 254SMo / XM-19 / S31803 /S32750 / S32205 / F50 / F60 / F55 / F60 / F61 / F65 etcMonel 400 / Monel K-500Inconel 600 / Inconel 601 / Inconel 625 / Inconel 617 / Inconel 690 / Inconel 718 / Inconel X-750Incoloy A-286 / Incoloy 800 / Incoloy 800H / Incol

Contact Now

Monel K500 Round BarMonel K500 Round Bar is a age hardened alloy, whose basic composition makeup consists of elements like Nickel&Copper. Which combines the corrosion resistance of Alloy 400 with the high strength, fatigue resistance and erosion resistance.Monel K500 is a nickel-copper alloy, precipitation hardenable through additions of aluminium and titanium. Monel K500 has excellent corrosion resistant characteristics.

Contact Now

600 alloy (UNS NO6600) The alloy is widely used in the chemical industry for its strength and corrosion resistance. Applications include heaters, stills, bubbles and condensers for fatty acid processing; Evaporator tubes, segments and spalling pans for the manufacture of sodium sulfide; And equipment for processing plants.

Contact Now

ncoloy617/alloy617 alloy processing and welding properties: the alloy is easy to process in a variety of hot and cold processing, although due to the high strength, high-power equipment is required. Product Parameter:Prdouct NameNickel Alloy BarGradeHastelloy: Hastelloy B / B-2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N;Inconel: Inconel 100/600/601/602CA/617/625713/718738/X-750,Carpenter 20;Incoloy: Incoloy 800/800H/800HT/825/925/926;Monel: Monel 400/K500Nimonic: Nimonic 75/80A/90 ;OuterDiameter (OD)Peeling Bar: 16~180mmCold Drawn Bar: 4.76~120mm (All sizes can be customized)Forged Bar: 180

Contact Now

This alloy has the following properties.1. High resistance to pitting and crevice corrosion in halide media and acidic media containing H2S2. Effective resistance to chloride ion stress corrosion cracking in practical applications3. Excellent corrosion resistance to all kinds of corrosion in the usual oxidizing and reducing environment4. Mechanical properties are improved compared to Cronifer 1925 LC-Alloy 904 L5.

Contact Now

Inconel 718 Round BarInconel 718 Round bars are stable cylindrical bars made from the high-strength & corrosion-resistant nickel-based superalloy recognised as Inconel 718. The spherical bar is normally machined or solid to the favored structure & size, and it can be heat-treated to decorate its mechanical properties. The aerospace, nuclear, & gasoline turbine industries oftentimes use these bars requiring high-temperature and high-stress resistance. Inconel 718 spherical bar is handy in a number of sizes & lengths.

Contact Now

Bars are the most common raw material used by industries in various shapes and sizes, one such shape of the bar is Alloy 926 Round Bar. The most common shapes of Bars are Alloy 926 Round Bar, Alloy 926 Square Bar, Alloy 926 Rectangle Bar, and Alloy 926 Hex Bar.

Contact Now

Alloy 400 from NeoNickel has superb corrosion resistance, particularly in neutral and alkaline salts. It is also one of a limited number of alloys that can be used in conjunction with hydrofluoric acid and fluorine. With high nickel content, this alloy is immune to chloride-induced stress corrosion cracking.

Contact Now