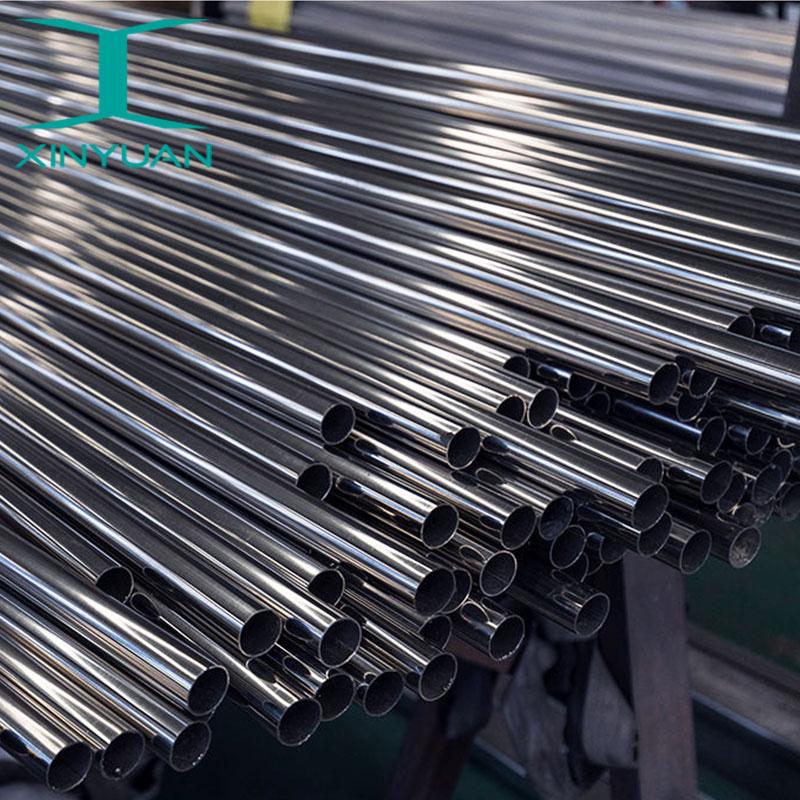

Cold Drawn Stainless Steel Welded PipeIt is mostly used to manufacture parts that are resistant to atmospheric, water vapor, water and oxidative acid corrosion.Cold Drawn Stainless Steel Welded Pipe videoProduct Parameter:DescriptionItemStainless Steel Pipe / TubeSteel grade200 series 300 series 400 series 600 series 900 seriesStandardASTM A213,A312,ASTM A269,ASTM A778,ASTM A789,DIN 17456, DIN17457,DIN 17459,JIS G3459,JIS G3463,GOST9941,EN10216, BS3605,GB13296Material201 202 203 204 301 302 303 303se 304 304L 304N1 304N2 304LN 305 309 309S 310 310S 316 316L 316N 316J1 316J

Contact Now

TP310s seamless/welded stainless steel pipe/tube for Instrumentation Stainless steel pipe is a kind of hollow long round steel, which is widely used in petroleum, chemical, medical, food, light industry, mechanical instruments and other industrial transmission pipelines as well as mechanical structural components. In addition, when the bending and torsional strength are the same, the weight is light, so it is also widely used to manufacture mechanical parts and engineering structures.

Contact Now

introduction:Welded stainless steel pipe provides us a large diameter but low cost solution. Our welding process mainly is Plasma-Arc Welding(PAW), its biggest diameter could reach 3000mm. If other process is required, please state it in the requirement of stainless steel tubings.Stainless steel contains chromium which provides the properties of corrosion resistance at high temperatures. Stainless steel can withstand corrosive or chemical environments due to its smooth surface.

Contact Now

Grade 410 stainless steel is a basic, general purpose, martensitic stainless steel. It is used for highly stressed parts, and provides good corrosion resistance, high strength and hardness. Grade 410 stainless steel pipes contain a minimum of 11.5% chromium.

Contact Now

Providing the ultimate in corrosion, rust, stain and temperature resistance, the 410 Stainless Steel is the most universal screw for almost any application and provides:Stainless steel finish provides a decorative aesthetic and superior corrosion resistanceSuperior holding strengthThe ability to withstand harsh conditionsLong-lasting performanceA reputation for quality, strength and ease of installation from industry professionalsOTHER APPLICATIONSPool enclosures, environmental, coastal construction, water and utilities, boat building, wastewater and sanitation.FAMILYHEAD TYPEANCHOR

Contact Now

Nickel when added to several stainless steel alloys brings about an increase in their corrosion resistance properties. The absence of a higher content of nickel in the Stainless Steel 201 Welded Pipe led to the addition of higher contents of both manganese and nitrogen in its chemistry.

Contact Now

410 Stainless Steel Checker Plate410 stainless steel contains 0.15% carbon and 13% chromium. It is a semi martensitic stainless steel. After quenching and tempering, it has high strength and toughness. It has good corrosion resistance and machining performance in a weak corrosive medium with a temperature not exceeding 30 degrees. It also has rust and corrosion resistance in wet atmosphere and fresh water, and has high thermal stability below 700 ℃.

Contact Now

Grade 410 belongs to the martensitic family of stainless steel alloys. Its high chromium content, which averages about 11.5 percent of its total composition, gives this stainless steel outstanding resistance to corrosion and excellent durability.

Contact Now

304 304L Stainless Steel304 is a variation of the basic 18-8 grade, Type 302, with a higher chromium and lower carbon content. Lower carbon minimizes chromium carbide precipitation due to welding and its susceptibility to intergranular corrosion. In many instances, it can be used in the ”as-welded“ condition, while Type 302 must be annealed in order to retain adequate corrosion resistance. Type 304L is an extra low-carbon variation of Type 304 with a 0.03% maximum carbon content that eliminates carbide precipitation due to welding.

Contact Now

Stainless steel 316l din 1.4404 1.4435 welded pipes aenhance great weldability in addition to great corrosion resistance and excellent strength properties. These welded pipes are formed with optimum quality of stainless steel material.

Contact Now

304 stainless steel welded pipe is an excellent candidate for most processing techniques as well as both indoor and outdoor applications. This product has a semi-smooth, dull grey finish with accurate dimensions throughout length. 304 stainless steel is a high strength material with excellent corrosion resistance making it a great candidate for liquid passageways.

Contact Now

This kind of steel pipe can be divided into stainless steel seamless steel pipe and stainless steel welded pipe (seam pipe) two categories.According to the different manufacturing process can be: hot rolling, extrusion, cold drawing and cold rolling these basic types, according to the shape of the section and can be divided into round pipe and special-shaped pipe, widely used is circular steel pipe, but there are some square, rectangular, semicircular, hexagonal, equilateral triangle, octagonal special-shaped stainless steel pipe.Shaped Stainless Steel Pipe1.Not easily rust, acid resistance an

Contact Now

Decorations, constructions, food industry, etc..Stainless steel pipe can be made according to the customers requirements.Product Parameter:NameWelded Steel PipesSizeOuter diameter :6 mm - 630mmThickness : 1- 40mmLength : 2000/2440/3000/5800/6000mm etcOrdinary DimensionDN6 /DN8/DN15/DN25/DN32/DN40/DN50/DN80/DN100/DN200/DN500 etcMaterial Series201 / 202 / 304 /310/310S/316/316L/409/409L/410/410S /420/430 etcTechniquePre-galvanized / Hot-dipped galvanized / Hang-planting galvanizationSteel GradeQ195, Q235A-B, Q345A-E, 20#, 10#,16Mn, ASTM A36,ASTM A500, ASTM A53, ASTM 106, SS400, St37, St52,

Contact Now

Pipe flanges connect pipes, valves, pumps and other equipment in a piping system. Flanges are usually welded or screwed into the systems and then joined with bolts. The eight types of pipe flanges are available in round, square and rectangular shapes.Blind FlangesA blind, or blanking, flange is a round plate with no center hold (but with bolt holes) that closes the ends of piping systems.Lap Joint FlangesPiping fitted with lapped pipe or with lap joint stub ends often use lap joint flanges.

Contact Now

Stainless Steel 410 is an austenitic stainless steel that combines excellent high temperature properties with good ductility and weldability. It is typically used for elevated temperature applications as its high chromium and nickel content provide solid corrosion resistance, excellent resistance to oxidation, and superior strength in temperatures up to 2100°F.

Contact Now

Although this austenitic alloy is a precipitation hardened metal, the 202 Stainless Steel Welded Tubes work well even in conditions where the temperatures are really low. Several carbon or alloy steels tend to crack when used in low temperatures, as the media tends to expand, leading to intermolecular forces applying pressure on the pipes. This pressure in low temperature environments could cause regular pipes to crack, thus leading to failure in the entire processing unit.

Contact Now

2205 2507 904L 254SMO POLISHED STAINLESS STEEL SEAMLESS/WELDED PIPE MANUFACTURERItemStainless Steel Tube/PipeSteel grade200series,300 series,400series,duplexStandardASTM A213,A312,ASTM A269,ASTM A778,ASTM A789,DIN 17456,DIN17457,DIN 17459,JIS G3459,JIS G3463,GOST9941,EN10216,BS3605,GB13296Material304,304L,309S,310S,316,316Ti,317,317L,321,347,347H,304N,316L, 316N,201,202SurfacePolishing,annealing,pickling,brightTypehot rolled and cold rolledstainless steel round pipe/tubeSizeWall thickness1mm-150mm(SCH10-XXS)Outer diameter6mm-2500mm (3/8"-100")stainless steel square pipe/tubeSizeWall

Contact Now

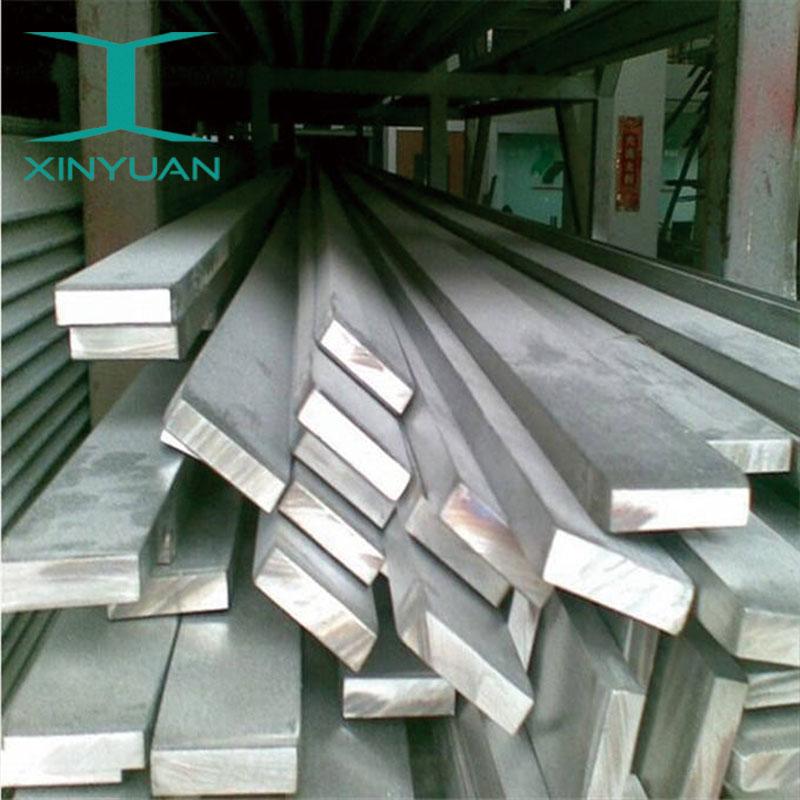

410 stainless steel flat steel is widely used in decorative pipe, kitchenware, products with pipe. Food technology, sugar and wine making equipment. Beer piping. Cooling equipment. Water treatment equipment, electric transportation equipment, mechanical automation equipment, medical equipment, automobile accessories. Boiler auxiliary machine. Petrochemical, printing and dyeing equipment, heat exchanger, water supply and other industries.

Contact Now

Our 301 Stainless Steel Welded Pipes are made of 301 stainless steel, which can exert strong anti-corrosion properties in air or chemically corrosive media, and are often used in production, chemical equipment and other fields. They have a smooth surface and good corrosion resistance, which is not caused by surface treatment such as electroplating, but takes advantage of the inherent surface properties of stainless steel.

Contact Now

410 stainless steel wire is preheated to 400 ° f to prevent cracking, and then usually heat treated at 2000 ° F. Thanks to various heat treatments, 410 stainless steel has many characteristics. Our 410 stainless steel can be used under a variety of conditions, including condition a, condition h, condition 2 and condition 3. One of the most common oil replenishment conditions is the QDT of each NACE.

Contact Now

2507 dual-phase steel density: 8.03g/cm3, melting point: 1300-1390 ℃, magnetic: noneHeat treatment: heat preservation between 1000-1052℃ for 1-2 hours, rapid air cooling or water cooling.Mechanical properties: tensile strength: σb≥795Mpa, yield strength σb≥550Mpa: elongation: δ≥15%, hardness ≤310 (HB)Product Parameter:ItemStandardMaterialStainless SteelASTM201, 202, 301, 304, 304L, 304N, XM21, 304LN, 305, 309S, 310S, 316, 316Ti, 316L, 316N, 316LN, 317, 317L, 321, 347, 329,405, 409, 430, 434, 444, 403, 410, 420, 440A, etc.EN1.4372, 1.4373, 1.4319, 1.4301, 1.4306, 1.4315, 1.4303, 1.4833, 1.4845,

Contact Now

409 stainless steel is a ferritic stainless steel commonly used in machinery, construction and other projects. Due to the presence of austenite grains, the mechanical properties are greatly improved.

Contact Now

S32750 Welded Pipes are used in offshore platforms, Mechanical and structural components, sea-water piping, Desalination Plants, Heat exchangers and chemical processing industries.Product Parameter:SpecificationSizeOuter Diameter: 6-2500mm (3/8”-100”);Wall Thickness: 1-150mm (SCH10-XXS);Length: As your requestProcessWeldedStandardASTM, DIN, ISO, EN, JIS, GB, etcMaterial200 series: 201,202,202Cu,204Cu,300 series: 301, 303/Cu, 304/L/H, 304Cu, 305, 309/S, 310/S, 316/L/H/Ti, 321/H, 347/H, 330,400 series: 409/L, 410, 416/F, 420/F, 430, 431, 440C, 441, 444, 446,600 series: 13-8ph, 15-5ph, 17-4ph, 17

Contact Now